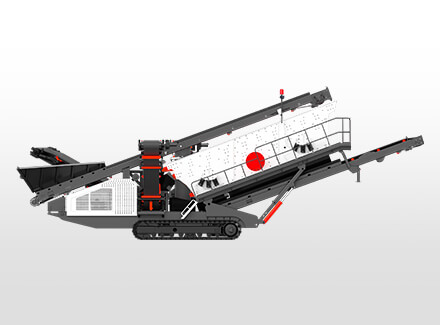

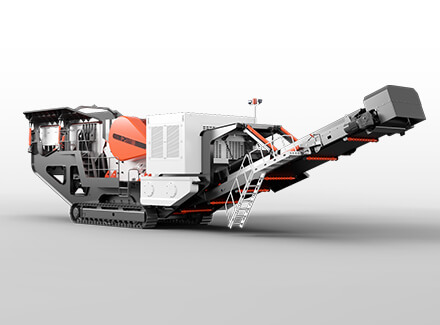

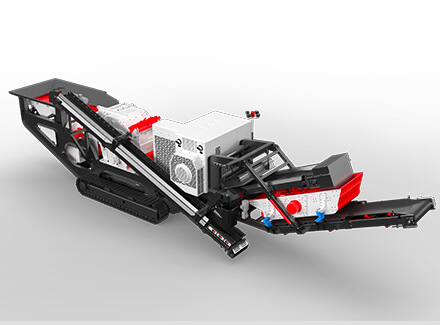

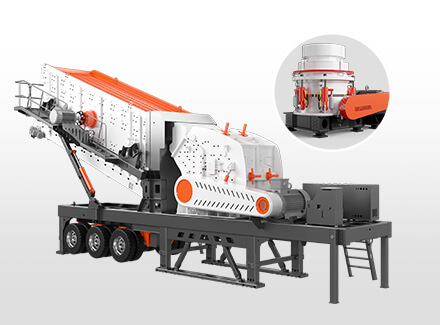

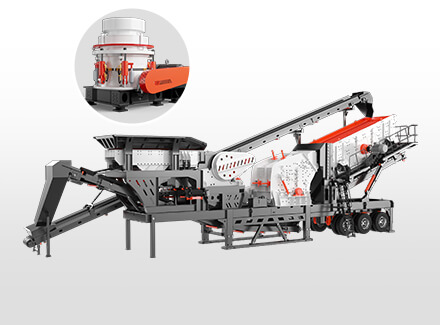

Product Introduction

The K series mobile crushing station has 12 models, with a maximum capacity of 650 tons/hour and a maximum feed of 1100X1200 mm, filling the gap in large-capacity mobile crushing equipment. At the same time, the multi-series host reserve not only meets the crushing needs of quarries and coal mining, but can also be used in the treatment of concrete and construction waste.

Applicable materials

iron ore, river pebbles, marble, limestone, basalt, diabase, ore tailings, construction waste and other materials.

Application scope

Widely used in road and bridge construction, urban construction, metallurgy, energy and other fields

Product Advantages

Shoe design, no infrastructure required

The self-developed machine body support device, a shoe, can be automatically folded during transportation, which is convenient for transportation; after entering the work area, simply level the ground and start working, saving a lot of infrastructure construction time, related material costs and labor costs. The process is simple.

The coarse crushing mobile crushing station integrates process equipment such as receiving, crushing, and transmission. Through the optimization of the process flow, it has good crushing performance for rock crushing, aggregate production, and open-pit mining.

Large crushing ratio

The coarse mobile crusher is equipped with high-quality jaw crusher and impact crusher main crushing equipment, which can crush hard and highly abrasive materials with a large crushing ratio.

Low transportation cost

The mobile crushing station can be driven directly into the raw material site and can crush the materials on site, eliminating the intermediate link of transporting the materials away from the site and then crushing them, greatly reducing the material transportation cost.

Product Parameter

Standard Model

model | Supporting Equipment | Supporting Equipment | Preparation capacity (t/h) | Dimensions |

| Model | Model | Feed size (mm) | Output (t/h) |

| KE600-1 | TSW0936 | PE600×900Ⅱ | ≤500 | 90-180 | ≤100-210 | 12150×2800×3960(mm) |

| KF1214Ⅱ-1 | TSW0936 | PFW1214Ⅱ | ≤500 | 110-190 | ≤120-210 | 12150×2800×4010(mm) |

| KJ98-1 | TSW1139 | HJ98 | ≤560 | 110-350 | ≤130-370 | 12150×2800×3960mm |

| KE750-1 | TSW1139 | PE750×1060 | ≤630 | 110-300 | ≤130-330 | 13030×3350×4840mm |

| KE760-1 | TSW1139 | PEW760 | ≤640 | 150-310 | ≤170-330 | 13030×3350×4600(mm) |

| KF1214Ⅱ-1 | TSW1139 | PFW1214Ⅱ | ≤500 | 110-190 | ≤140-230 | 13030×3350×4600(mm) |

| KJ110-1 | TSW1345 | HJ110 | ≤660 | 215-490 | ≤235-520 | 13250×3430×4720(mm) |

| KE860-1 | TSW1345 | PEW860 | ≤720 | 200-420 | ≤230-450 | 14600×3280×5070(mm) |

| KJ125-1 | TSW1345 | HJ125 | ≤800 | 280-620 | ≤310-650 | 14532×3268×5192(mm) |

| KF1315Ⅱ-1 | TSW1345 | PFW1315Ⅱ | ≤600 | 180-280 | ≤190-310 | 14532×3268×4862(mm) |

| KF1415Ⅱ-1 | TSW1548 | PFW1415Ⅱ | ≤700 | 280-450 | ≤310-480 | 14759×3475×4870(mm) |

| KE1100-1 | TSW1548 | PEW1100 | ≤930 | 300-600 | ≤350-650 | 14759×3475×5120(mm) |

English

English

中文

中文