Product Introduction

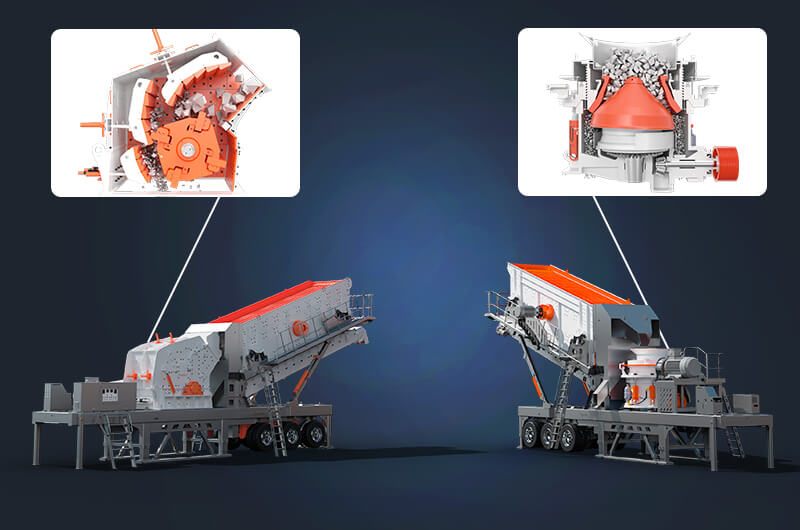

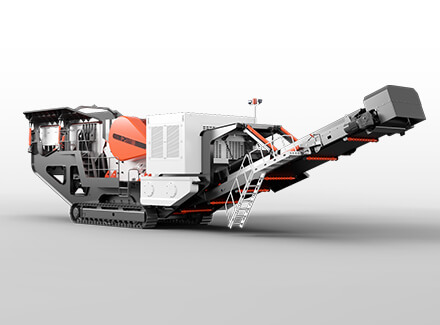

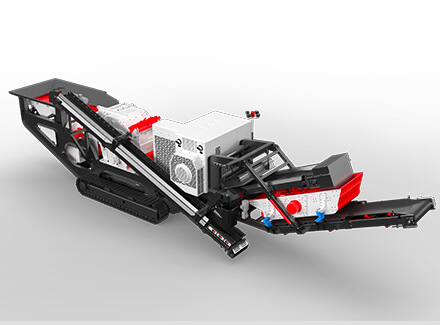

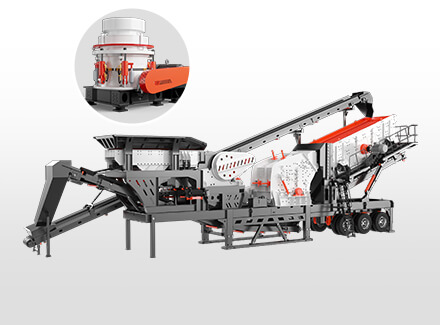

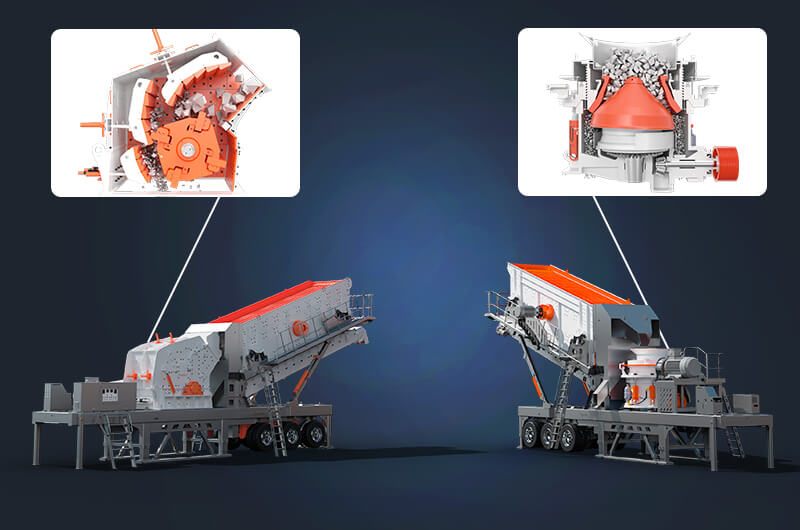

The K series medium and fine crushing and screening mobile station has 18 models, which are mainly used for secondary crushing and pure screening operations. With the help of a vibrating screen with adjustable installation angle, the whole machine has a larger processing capacity and better adaptability to the production needs of users at different stages.

Applicable materials

river pebbles, mountain rocks (limestone, granite, basalt, diabase, andesite, etc.), ore tailings, artificial sand making of stone chips.

Application scope

Widely used in road and bridge construction, urban construction, metallurgy, energy and other fields.

Product Advantages

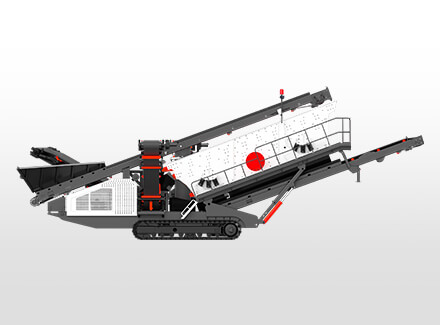

Shoe design, no infrastructure required

The machine body support device, a shoe developed independently by us, can be automatically folded during transportation, which is convenient for transportation; after entering the work area, the machine can be put into operation by simply leveling the ground, saving a lot of infrastructure construction time, related material costs and manpower.

Effective and reliable medium and fine crushing host equipment

It has the advantages of large crushing ratio, strong processing capacity, stable and reliable performance.

Add the function of adjusting the vibrating screen

Add the function of adjusting the installation angle of the vibrating screen to make the whole machine more powerful.

Flexible configuration of the host

Adaptable host equipment switching, dozens of models can be matched to meet the personalized needs of customers.

Easy to install

Flexible and maneuverable parking function, quickly enter the working mode.

Product Parameter

Standard Model

model | Supporting Equipment | Supporting Equipment | Preparation capacity (t/h) | Dimensions |

| model | model | Feed size (mm) | Output (t/h) |

| KC75-2 | 3YZS1848 | CS75B | ≤102-175 | A | ≤A+(20~50) | 14730×3620×6680(mm) |

| KT100-2 | 3YZS1848 | HST100H1 | ≤52-192 | A | ≤A+(20~50) | 14730×3620×6680(mm) |

| KC160-2 | 3YZS1860 | CS160B | ≤168-192 | A | ≤A+(30~70) | 14860×3850×7100(mm) |

| KT160-2 | 3YZS1860 | HST160H1 | ≤72-288 | A | ≤A+(30~70) | 14860×3850×7100(mm) |

| KH300-2 | 3YZS1860 | HPT300C2 | ≤84-168 | A | ≤A+(30~70) | 14860×3850×7100(mm) |

| KT250-2 | 3YZS1860 | HST250H1 | ≤88-360 | A | ≤A+(30~70) | 14860×3850×7100(mm) |

| KH300-2 | 3YZS2160 | HPT300C2 | ≤84-168 | A | ≤A+(40~90) | 14880×3910×7120(mm) |

| KT250-2 | 3YZS2160 | HST250H1 | ≤88-360 | A | ≤A+(40~90) | 14880×3910×7120(mm) |

| KH300-2 | 4YZS2160 | HPT300C2 | ≤84-168 | A | ≤A+(20~80) | 14880×4260×7610(mm) |

| KF1214-2 | 3YZS1860 | PF1214 | ≤300 | 90-180 | ≤120-240 | 14860×3660×7100(mm) |

| KF1214-2 | 3YZS1860 | PFW1214Ⅲ | ≤250 | 90-190 | ≤120-250 | 14860×3660×7100(mm) |

| KF1315-2 | 3YZS2160 | PF1315 | ≤300 | 120-250 | ≤150-320 | 14880×3910×7120(mm) |

| KF1315-2 | 3YZS2160 | PFW1315Ⅲ | ≤300 | 150-280 | ≤180-350 | 14880×3910×7120(mm) |

| KF1315-2 | 4YZS2160 | PFW1315Ⅲ | ≤300 | 150-280 | ≤150-280 | 14880×4260×7610(mm) |

| KF1318-2 | 3YZS2160 | PFW1318Ⅲ | ≤300 | 220-350 | ≤250-430 | 14880×3910×7120(mm) |

| KS1848-1 | 3YZS1848

|

| 50-250 | 50-250 | ≤70-300 | 14870×4305×6680(mm) |

| KS1860-1 | 3YZS1860 |

| 60-320 | 60-320 | ≤70-350 | 14850×4305×7100(mm) |

| KS2160-1 | 3YZS2160 |

| 80-400 | 80-400 | ≤90-450 | 14870×4305×7120(mm) |

English

English

中文

中文