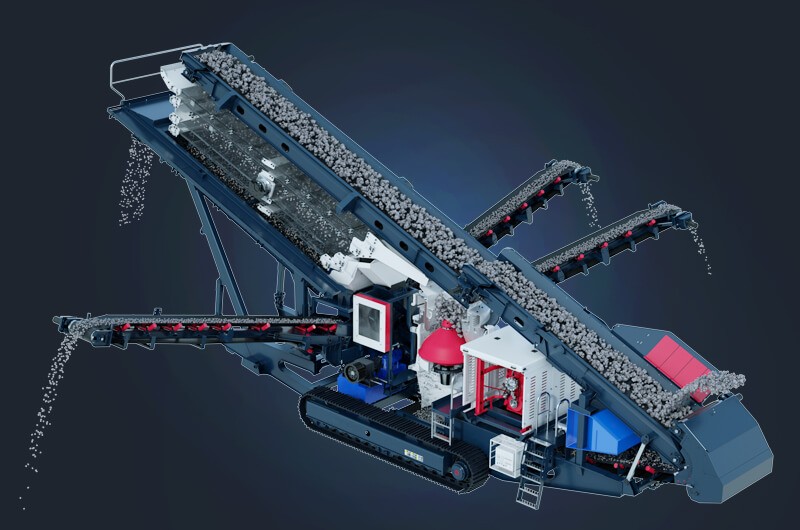

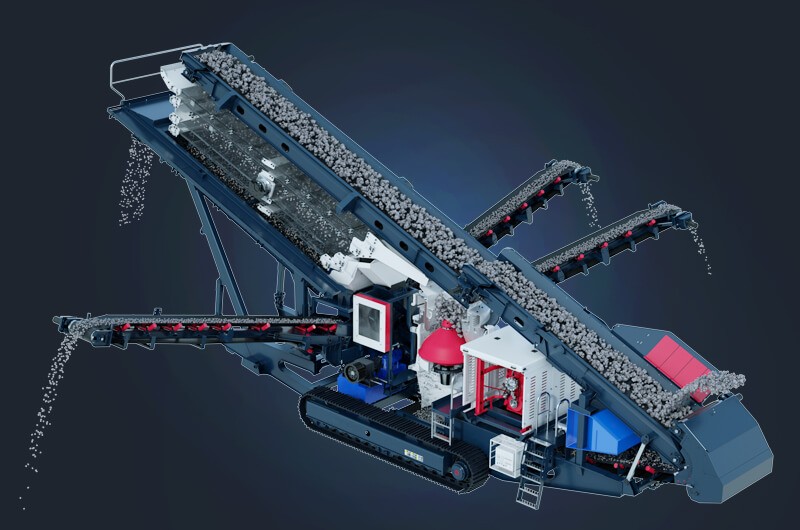

Product Introduction

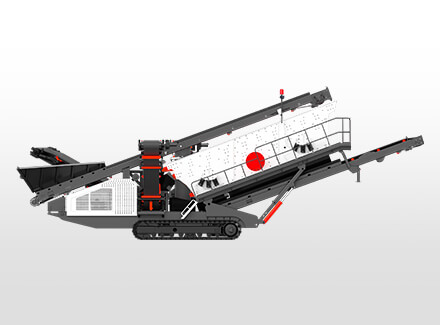

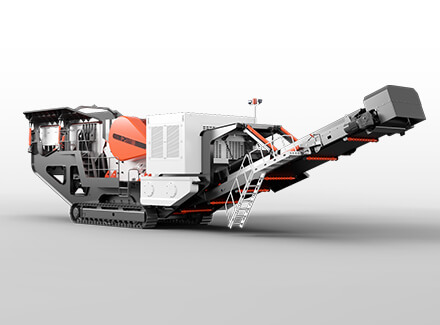

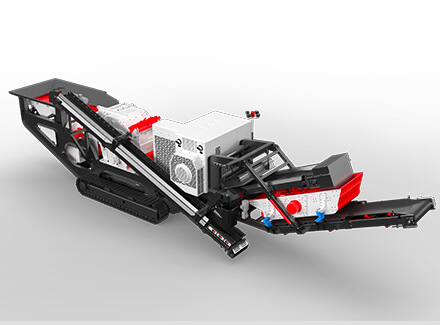

Crawler mobile cone crushing station is a new type of cone crusher developed by our company after optimizing design based on the introduction and absorption of European and American hydraulic cone crusher technology. It has low crushing energy consumption and strong crushing force. It has the characteristics of high reliability, large production capacity, high degree of automation, simple operation and maintenance, good product particle shape, and low cost of wearing parts.

Increase the eccentric moment and improve the processing capacity. High swing frequency and layer compression crushing bring higher output, greater crushing ratio and better particle shape. Thickened liner extends life; greatly increases the strength of the main shaft, can obtain greater installed power, can be quickly combined with jaw crusher, screening and other series of products to form a complete crushing production line.

Applicable materials

Crushing of various natural stones (limestone, river pebbles, granite, basalt, etc.), construction waste (rubble, road concrete, reinforced concrete), coal mines and metal mines, etc.

Application fields

Widely used in road and bridge construction, urban construction, metallurgy, energy and other fields.

Product Advantages

It can be used for both oil and electricity, with high production capacity and energy saving of about 70%.

It is efficient and stable, and can produce products within 30 minutes without installation and debugging.

One-button start/stop operation, combined with a wireless remote control, can reduce the number of auxiliary operators.

Product Parameters

| Equipment/Parts | Parameters | Model |

|---|

| THP200 | THP300 | THP400 |

|---|

| Feeder | Specification | B800×4.6m | B1000×4.6m | B1000×4.6m |

| Drive mode | Variable frequency motor + reducer drive (1KW) | Frequency conversion motor + reducer drive | Frequency conversion motor + reducer drive |

| Crusher | model | HP200 | HP300 | HP400 |

| Maximum feed size | 150mm | 200mm | 260mm |

| Minimum outlet | 10mm | 20mm | 16mm |

| Motor power | 160KW | 220KW | 280KW |

| Frame | Load-bearing | 60T | 60T | 60T |

| Structural Materials | Q345B welding | Q345B welding | Q345B welding |

| Return screen | Specification | YK1500×3800 | YK1600×4000 | YK1500×3800 |

| Drive mode | Vibration motor (3.7KW×2) | Vibration motor (3.7KW×2) | Vibration motor (3.7KW×2) |

| Main belt conveyor | Specification | B1000×12.5m | B1200×12.5m | B1200×10.6m |

| Drive mode | Motor reducer drive (15KW) | Motor reducer drive (15KW) | Motor reducer drive (15KW) |

| Belt Type | EP300-B1000×5(6.5+1.5) | EP300-B1000×5(6.5+1.5) | EP300-B1000×5(6.5+1.5) |

| Under-screen belt conveyor | Specification | B1000×5.6m | B1200×5.6m | B1200×6.2m |

| Drive mode | Motor reducer drive (7.5KW) | Motor reducer drive (7.5KW) | Motor reducer drive (7.5KW) |

| Belt Type | EP300-B1000×3(4.5+1.5) | EP300-B1200×3(4.5+1.5) | EP300-B1200×5(6.5+1.5) |

| Return belt conveyor | Specification | B500×12.5m | B500×12.5m | B650×12.5m |

| Drive mode | Motor reducer drive (7.5KW) | Motor reducer drive (7.5KW) | Motor reducer drive (7.5KW) |

| Belt Type | EP200-B500×3(4.5+1.5) | EP200-B500×3(4.5+1.5) | Endless polyester canvas belt |

| Transfer belt conveyor | Specification | B500×2.4m | B500×2.4m | B500×2.4m |

| Drive mode | Motor reducer drive (4KW) | Motor reducer drive (4KW) | Motor reducer drive (4KW) |

| Belt Type | EP200-B500×3(4.5+1.5) | EP200-B500×3(4.5+1.5) | EP200-B500×3(4.5+1.5) |

| Generator Set | power | 320KW engine unit | 500KW engine unit | 500KW engine unit |

| Electrical System | Control method | Cone motor frequency conversion start, other motors direct start |

| Hydraulic system | Core Features | Load Sensing Pump Valve Group |

| Additional Features | Hydraulic automatic lifting |

English

English

中文

中文