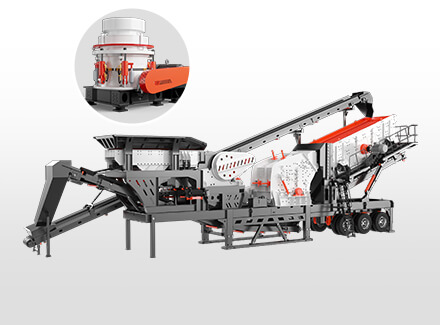

Product Introduction

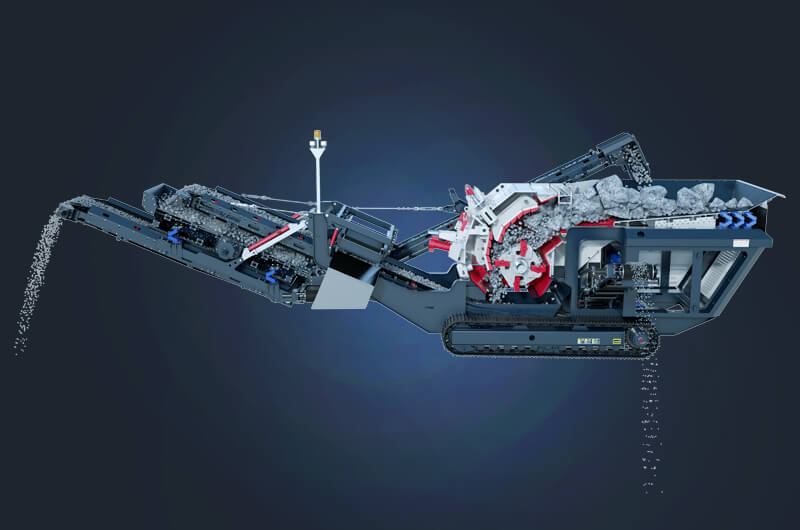

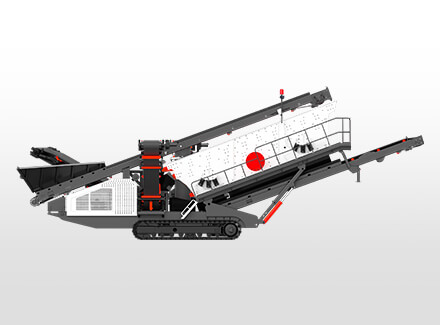

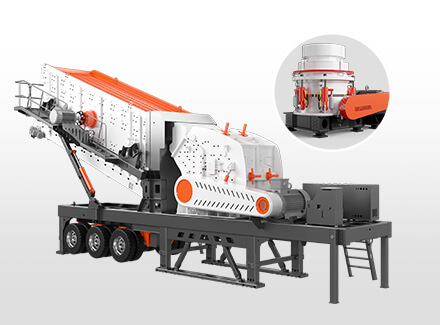

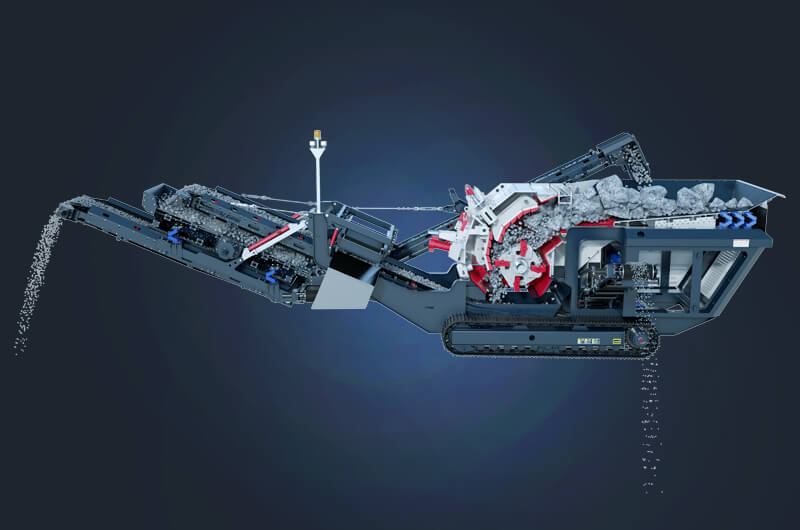

Crawler mobile impact crushing station is a brand-new design for construction solid waste. It features double-chamber crushing mainframe, good finished product particle shape, large crushing ratio, heavy-duty rotor and greatly improved production capacity. It is mainly used for resource utilization of construction solid waste, such as crushing in house demolition and recycling of road concrete; aggregate crushing in asphalt and concrete mixing plants, material crushing in other industries, primary crushing, medium crushing and fine crushing in the crushing process of mining industry, crushing of medium-soft hardness natural stone with compressive strength below 150 MPa and reprocessing of construction residues.

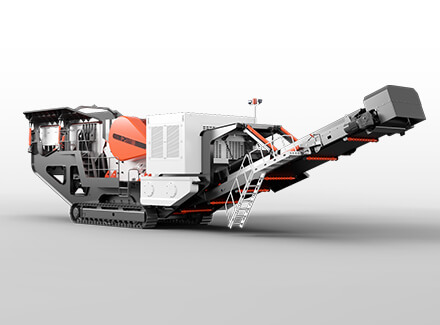

The newly developed hybrid mobile impact crusher is a hybrid type with oil and electricity as standard. Thanks to its compact shape and weight, it is easy to transport and has a wide range of uses.

Applicable materials

rocks, pebbles, construction waste, tailings, iron ore, molybdenum ore, coal, glass, ceramics, etc.

Application

quarrying, recycling, construction and demolition waste, aggregates, industry, environmental protection

Product advantages

High capacity and good particle shape.

High-performance impact crusher, high capacity and good particle shape.

Real-time adjustment, convenient and fast.

The feed speed is adjusted in real time according to the load of the crusher to ensure good material flow.

Integrated unit.

The core equipment is the new CI series impact crusher, with reasonable matching of speed and power to meet different applications of coarse crushing, medium and fine crushing and material recovery.

Large crushing chamber and large feed particle size.

Heavy-duty rotor, high wear-resistant material, large crushing chamber, so that the feed particle size is large, the product is stable, the output is high, and the crushing ratio is large.

Product Parameters

Hydraulic crawler chassisSpecificationDrive mode

| model | TF150 | T250 counterattack vehicle | TTF250 counterattacks against standard vehicles |

Feede |

Model | GZD1038 | ZDG1228 | ZDG1228 |

| Vibration Motor | 2x3.7KW | 5.5KW*2 | 5.5KW*2 |

Motor drive | Motor drive | Motor drive |

Crusher |

Model | LF150 | LF250 | LF250 |

Maximum feed siz | 400mm | 500mm | 500mm |

| Motor and drive mode | 160KW | 250KW | 250KW |

Motor drive | Motor drive | Motor drive |

Chassis |

| NS415E | NS415E | NS415E |

|

| Boat-shaped frame | Q345B welding | Q345B welding | Q345B welding |

| Main belt conveyor |

| B800*11m | B1200*11m | B1200*11m |

|

| Motor reducer | 11KW | 电机减速器驱动15KW | 电机减速器驱动15KW |

| Endless polyester canvas belt | | EP300-B1200*5(6.0+1.5) | EP300-B1200*5(6.0+1.5) |

| Transfer belt conveyor |

| Specification | B500*2m | B500*2.4m | B500*2.4m |

| Motor reducer | 4KW | Motor reducer drive 4KW | Motor reducer drive 4KW |

| Endless polyester canvas belt | | EP200-B500*3(4.5+1.5) | EP200-B500*3(4.5+1.5) |

| Under-screen belt conveyor |

| Specification | B1000*5m | B1200*6.2m | B1200*6.2m |

| Motor reducer | 5.5KW | Motor reducer drive7.5KW | Motor reducer drive7.5KW |

| Endless polyester canvas belt | | EP300-B1200*5(4.5+1.5) | EP300-B1200*5(4.5+1.5) |

| Return belt conveyor |

| Specification | B500*7.7m | B500*9.3m | B500*9.3吗、 |

| Motor reducer | 5.5KW | Motor reducer drive 4KW | Motor reducer drive 4KW |

| Endless polyester canvas belt | | EP200-B500*3(4.5+1.5) | EP200-B500*3(4.5+1.5) |

| Return screen |

| Specification | 2YK1530 | YS1320 | GLS1630FA |

| Motor | 11KW | 3.7KW*2 | 3KW*2 |

Motor drive | Motor drive | ROST spring |

|

| Iron remover |

| Specification | RCYQ-13 | RCYQ-13 | RCYQ-13 |

| Motor reducer | 3KW | Motor reducer drive 3KW | Motor reducer drive 3KW |

| Powertrain |

| Generator Set | 320KW Cummins generator set | 500KW generator set | 500KW generator set |

| Electrical System | It adopts PLC intelligent control system, has fault alarm and fault record query functions, visual workflow, simple operation, screen display of various parameters monitoring, and the engine can automatically adjust speed according to load conditions. | The main motor of the impact crusher is frequency conversion started, and other motors are directly started. The main electrical components are Schneider | The main motor of the impact crusher is frequency conversion started, and other motors are directly started. The main electrical components are Schneider |

| Hydraulic system | Belt conveyor folding cylinder and impact crusher main engine cylinder hydraulic pump, valve, station and oil pipe accessories | Unpacking and discharging gap adjustment, side discharging folding and return part disassembly, load sensitive, electro-hydraulic proportional valve travel valve group | Unpacking and discharging gap adjustment, side discharging folding and return part disassembly, load sensitive, electro-hydraulic proportional valve travel valve group |

English

English

中文

中文