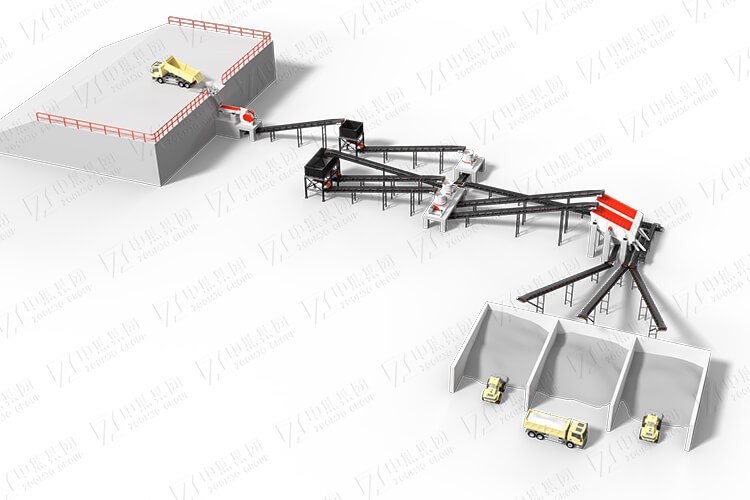

1. System Overview

This production line is suitable for hydropower engineering, highways, urban infrastructure and industrial building materials. It can process more than 10 kinds of hard materials such as river pebbles, granite, basalt, etc. The output supports customized configuration of 50-800 tons/hour, meeting the production needs of road aggregates, railway ballast and construction sand with different grading requirements.

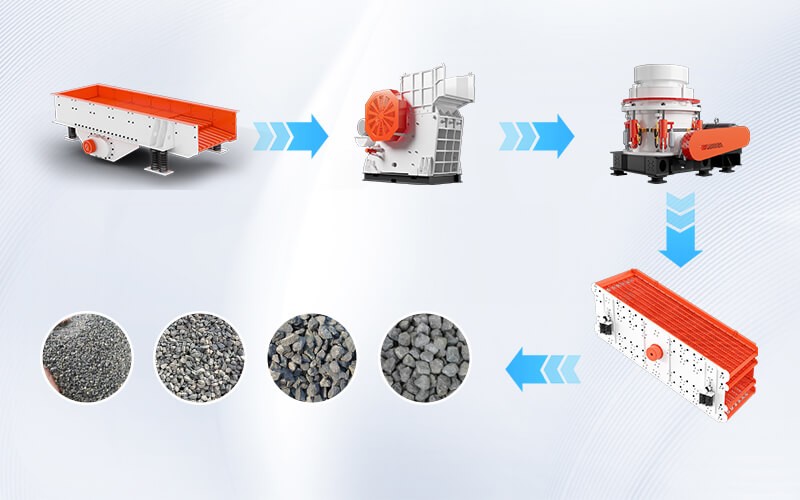

2. Core process system

Crushing and grading system

Primary crushing: jaw crusher (feed ≤ 1020mm)

Secondary crushing: European impact crusher/cone crusher

Shaping module: high-efficiency shaping machine

Screening system: multi-stage YK circular vibrating screen (2-4 layers of screen configuration)

3.Typical Configuration Scheme

700-800 tons of limestone processing per hour

Equipment configuration:

Vibrating feeder × 1

Jaw crusher × 1

Vibrating feeder × 2

European impact crusher × 4

Circular vibrating screen × 4

Process flow:

Explosive material → Jaw crusher coarse crushing (150-300mm) → Impact crusher fine crushing → Four-stage screening → Finished product warehouse (<30mm)>

Note: When the feed is less than or equal to 300mm, the material directly enters the European impact crusher for crushing, without the first stage of crushing.

600-700 tons of hard rock processing per hour

Core equipment:

Feeder ×1

Jaw crusher ×1

Cone crusher ×1

Shaping machine ×2

Circular vibrating screen ×4

Process features:

Granite/basalt → primary crushing by jaw crusher → secondary crushing by cone crusher → shaping optimization → three-stage screening → fine aggregate (cubic>90%)

Note: When the feed is less than or equal to 320mm, the material enters the cone crusher directly for crushing without the first stage of crushing.

Economical configuration with an output of 500-600 tons per hour

Equipment composition:

Feeder × 1

Jaw crusher × 1

Impact crusher × 3

Circular vibrating screen × 3

Technical advantages:

Explosive material → Jaw crusher coarse crushing (160mm-275mm) → Impact crusher fine crushing → Four-stage screening → Finished product warehouse (<30mm)>

Note: When the feed is less than or equal to 300mm, the material directly enters the European impact crusher for crushing, without the first stage of crushing.

4.Technical parameter comparison table

| Index items | Plan A | Plan B | Plan C |

|---|---|---|---|

| Applicable rock type | Medium Hard | High Hard | Medium Hard |

| Maximum feed (mm) | 1020 | 1020 | 930 |

| Finished product specifications (mm) | 0-5/5-10/10-30 | 0-5/5-16/16-31.5 | 0-5/5-20/20-40 |

5. Suggestions on Solution Selection

Priority configuration principle:

For materials with compressive strength ≤350MPa, use impact crusher.

For materials with high abrasiveness, it is recommended to use cone crusher + shaping machine.

For materials with soil content >8%, pre-screening is required.

This solution supports EPC general contracting services and provides a full-process solution of process design-equipment installation-commissioning and training, which can be customized according to the characteristics of raw materials and finished product requirements.

English

English

中文

中文