Overview

Ceramic proppant, also known as oil fracturing proppant, is a new type of material made of bauxite, manganese powder and admixtures, which is crushed, dried, batched, pelletized, calcined, cooled and screened. Ceramic sand has the advantages of high strength, compression and wear resistance, high roundness, good shock resistance and good permeability resistance.

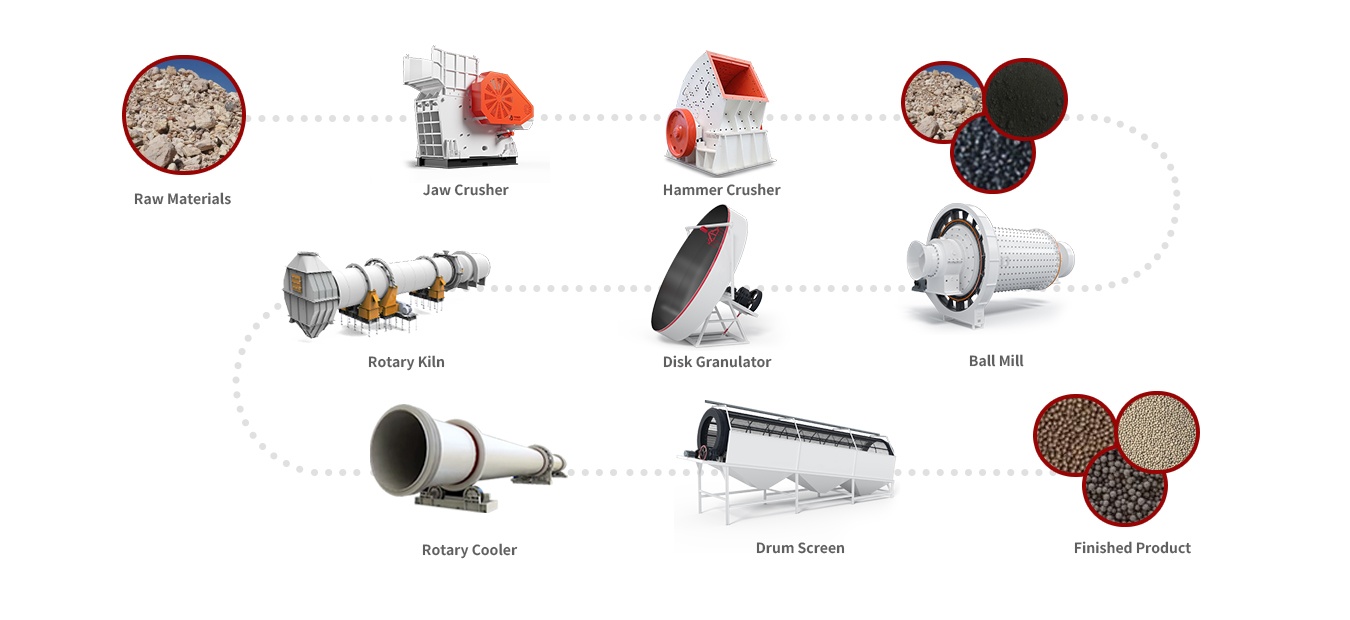

Process flow: crushing, batching, grinding, pelletizing, calcining, coal powder preparation, finished product cooling, screening, packaging, etc.

Outstanding Advantages

Advanced equipment

It has the characteristics of high production efficiency, fully automated control, and no dust pollution. Full process closed-loop design, raw material utilization rate > 95%.

Granulation experiments can be performed

We have a complete set of granulation experimental production lines, which can conduct experiments on customers' incoming materials, find out the appropriate granulation process for the materials, and provide guidance for actual production.

Environmentally friendly and pollution-free

The dust removal system adopts the design of automatic control system, and the dust removal effect meets the standards.

Low energy consumption and low cost

The production line adopts a sleeve drying structure, which recovers the heat lost by the drum wall, increasing the heat utilization rate from 30% to 70%. Taking a rotary kiln with a diameter of 2.5 meters as an example, it can save 450,000 to 500,000 yuan in energy costs annually.

Process

Raw material pretreatment

Crushing process

The bauxite raw material (block size 300-500mm) is crushed by a jaw crusher for primary crushing, and then crushed by a hammer crusher or impact crusher for secondary crushing. The particle size is controlled at ≤20mm, and some processes require ≤8mm.

After crushing, the material enters the buffer silo for temporary storage, and some of it needs to be dried (when the moisture content is >6%).

Drying

The waste heat from the fluidized bed furnace or rotary kiln is used to dry the crushed bauxite, with the hot air temperature at 800-900°C, reducing the moisture content of the material to the process requirements.

Ingredients and Grinding

Ingredients system

Bauxite is mixed with manganese powder, recycled materials, etc. in proportion and automatically measured by a speed-adjustable belt scale. The manganese element is used to reduce the sintering temperature and enhance the coloring of the product.

Grinding process

The closed-circuit grinding system consisting of a ball mill and a high-efficiency powder concentrator is used. The fineness of the raw material powder can reach above 400 meshes. The heat source can come from the exhaust gas of the rotary kiln or a special hot air furnace.

Pelletizing and Calcination

Pelletizing process

The raw material powder is added with water through a disc ball making machine to form balls with uniform particle size. After screening, qualified balls (particle size meets the standard) enter the rotary kiln, and the oversized particles return to the grinding system.

Rotary kiln calcination

The pellets are calcined at high temperature (1200-1500℃) in a tilted rotary kiln, with coal powder, gas or fuel oil as the fuel, to form high-strength ceramsite sand.

Cooling and post-processing

The high-temperature expanded clay sand is cooled to room temperature by a single cooler or naturally to prevent thermal stress from causing particle breakage.

Screening and packaging

Cooling system

The high-temperature expanded clay sand is cooled to room temperature by a single cooler or naturally to prevent thermal stress from causing particle breakage.

Screening and packaging

After cooling, the material is screened by a drum and classified by particle size (such as 20/40 mesh, 30/50 mesh, etc.). Qualified products are packaged and stored, and unqualified particles are returned to the grinding or ball making process.

Technical Parameters

Typical Configuration

| No. | Indicator | Unit | Quantity 1 | Quantity 2 | Quantity 3 | Quantity 4 |

|---|---|---|---|---|---|---|

| 1 | Product Output | t/a | 10000 | 20000 | 30000 | 50000 |

| 2 | Low density and high strength ratio | % | 80 | 80 | 80 | 80 |

| 3 | Main raw material usage | |||||

| ① | Bauxite | t/a | 10400 | 20800 | 31200 | 52000 |

| ② | Manganese powder | t/a | 200 | 400 | 600 | 1000 |

| ③ | Admixtures | t/a | 1000 | 2000 | 3000 | 5000 |

| 4 | Power consumption | |||||

| ① | New Water | t/a | 3000 | 6000 | 9000 | 15000 |

| ② | Electricity | kWh/a | 2800000 | 5600000 | 8400000 | 14000000 |

| ③ | Natural gas | Nm3/a | 1800000 | 3600000 | 5400000 | 9000000 |

| 5 | General plan transportation | |||||

| ① | Area | m2 | 30000 | 45000 | 61000 | 75000 |

| 6 | Capacity | name | 50 | 80 | 110 | 145 |

| 7 | Economic indicators | |||||

| ① | Project Investment | Ten thousand yuan | 960 | 1500 | 1800 | 2700 |

| ② | Investment profit rate | % | 84 | 84 | 84 | 84 |

| ③ | Payback period (after tax) | Year | 1.53 | 1.53 | 1.53 | 1.53 |

English

English

中文

中文