1. System Overview

Designed specifically for construction sand, it is suitable for hydropower projects, highways, municipal construction and other fields. It can process hard materials such as river pebbles and granite. The production capacity is 10-800t/h and can be flexibly configured to produce 0-5mm machine-made sand and multi-grade aggregates to meet the needs of high-standard concrete and special engineering sand.

2. Core Process System

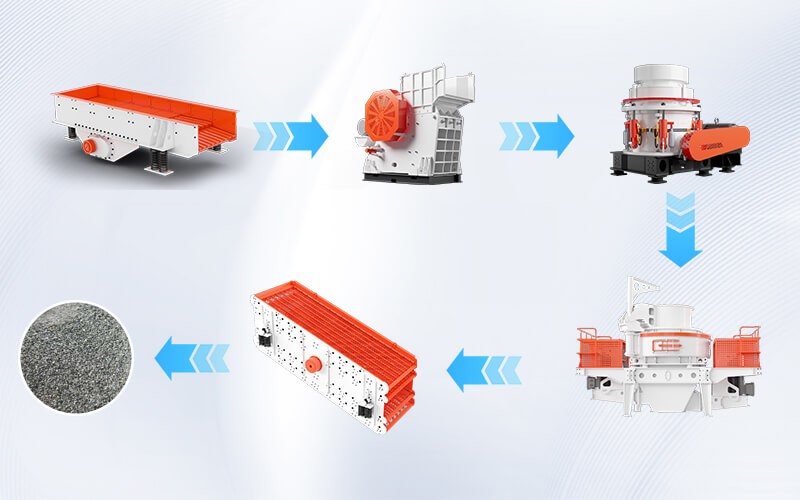

1. Modular combination of equipment

Crushing unit: jaw crusher (primary crushing) + impact crusher/cone crusher (secondary crushing)

Sand making unit: centrifugal impact sand making machine (fine crushing and shaping)

Screening unit: multi-layer circular vibrating screen (3YK/4YK series)

Auxiliary system: vibrating feeder, belt conveyor, dust removal device

2. Typical configuration plan

▌300-350 tons of limestone sand production per hour

Equipment configuration:

Feeder ×1

Jaw crusher ×1

Impact crusher ×2

Sand making machine ×2

Circular vibrating screen ×3

Process flow:

Explosive material (≤750mm) → jaw crusher → impact crusher → screening (40mm classification) → sand making → finished sand (0-5mm)

▌200-250 tons of hard rock sand (granite/river pebbles) per hour

Core equipment:

Feeder ×1

Cone crusher ×1

Sand making machine ×2

Screening machine ×2

Process features:

Hard rock → cone crusher → sand making and shaping → three-stage screening → cubic sand (powder content can be controlled)

▌150-200 tons per hour economical sand making line

Equipment composition:

Jaw crusher ×1

Impact crusher ×1

Sand making machine ×1

Dual-stage vibrating screen ×2

Advantages:

Modular and compact design, suitable for direct crushing of raw materials below 630mm, reducing energy consumption by 20%

4. Technical Parameters Comparison

headline indicato | PlanA | PlanB | PlanC |

|---|---|---|---|

Applicable material | limestone | granite | limeston |

Maximum feed (mm | 750 | 210 | 630 |

Finished sand specificatio | 0-3/3-5mm | 0-5/5-10mm | 0-5mm |

5. Suggestions on Solution Selection

Priority configuration principle:

For materials with high hardness (such as granite), use the combination of "cone crusher + sand making machine".

For raw materials with soil content > 5%, a sand washing module is required.

When the requirements for machine-made sand grading are high, add a wind separation powder removal machine.

Efficiency-enhancing measures:

The sand making machine peripheral guard plate is made of high chromium alloy, which increases its service life by 3 times.

Screen quick-change structure (spec switching can be completed in 10 minutes).

Support EPC general contracting services, provide full-process solutions from process design to equipment selection to installation and commissioning, and customize dry/wet sand making processes according to the characteristics of raw materials.

English

English

中文

中文