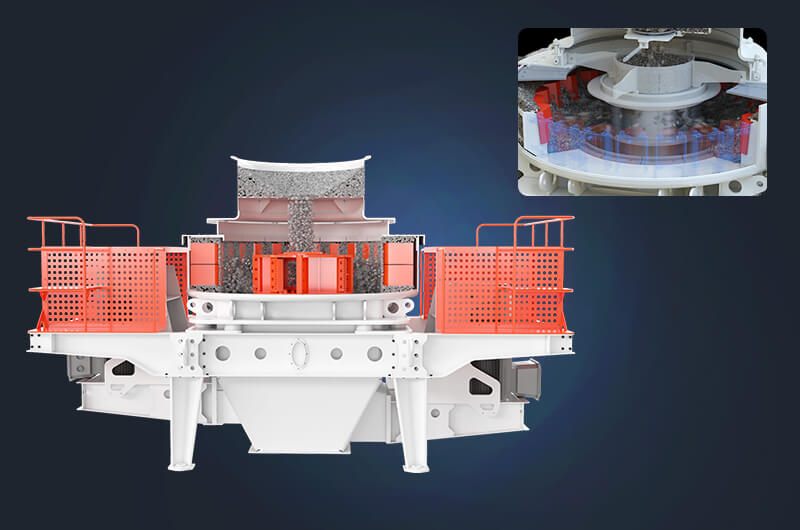

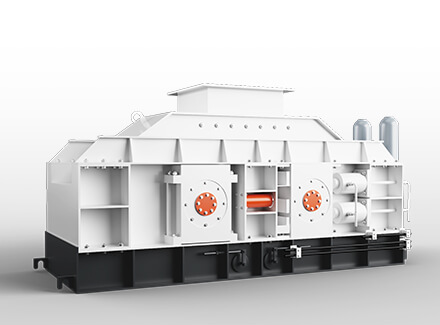

Sand making machine

Applicable materials: bluestone, granite, fluorite, river pebbles, quartz sand, limestone, quartz stone, etc.

Applicable materials: bluestone, granite, fluorite, river pebbles, quartz sand, limestone, quartz stone, etc.

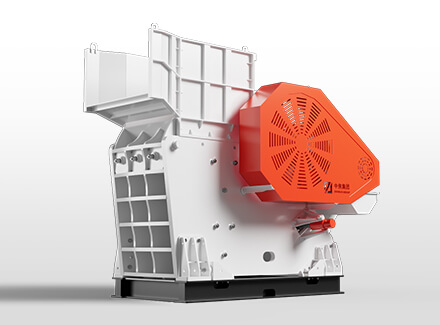

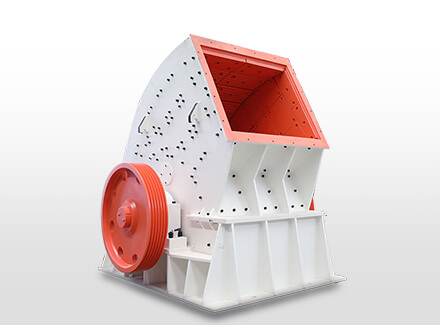

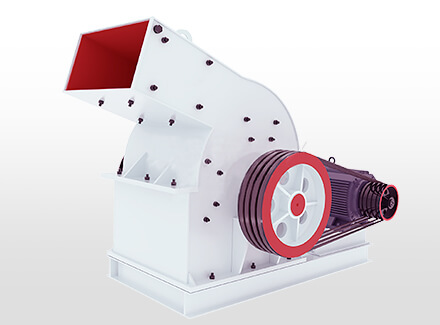

The impact crusher is also called a sand making machine. It is a new type of crushing and sand making equipment. It has a simple structural design and intelligent operation. The material self-lining in the impeller and vortex crushing chamber greatly reduces the cost of wear parts and maintenance workload. The deep cavity impeller increases the throughput by 30%, has high work efficiency, and is widely used. It is widely used in the medium and fine crushing of various hard and brittle materials such as rocks, quartz stones, river pebbles, and coal gangue. It is particularly suitable for construction sand and road sand.

The impact crusher effectively solves the "iron pollution" problem in the crushing process of raw materials such as glass and the "steel stuck" problem in the crushing process of steel slag. The clever internal airflow self-circulation eliminates dust dispersion.

Application: highways, buildings, bridges

Finished product specifications: 0-5mm, 5-10mm

Through the optimized design of the deep cavity rotor, the material throughput is increased by about 30%.

The new impeller design of the sand making machine optimizes the material flow, with an capacity of up to 650 tons/hour.

The machine has fine crushing and coarse grinding functions. The product is cubic, with good particle size and very low flake content.

The sand making machine is green and environmentally friendly during operation.

Thin oil lubrication system and automatic maintenance. Under the same capacity, the power consumption can be reduced by 10-40%.

Factory visit and special car reception: free special car reception, on-site inspection of equipment production process;

Scientific selection support: the technical team customizes equipment configuration solutions to meet production needs;

Technical training and debugging: professional personnel are on-site to guide installation and debugging to ensure efficient operation of equipment;

Lifetime after-sales: commitment to lifelong technical support;

Direct shipment from the factory workshop to prevent non-standard replacement

| Model | Soft Material | Hard Material | Sand Making | Plastic Surgery | Spindle Speed (r/min) | Power (kw) | Overall Dimension (mm) |

|---|---|---|---|---|---|---|---|

| VSI5X7615 | 35 | 30 | 150-280 | 70-140 | 1700-1900 | 75×2 | 4100×2330×2300 |

| VSI5X8522 | 40 | 35 | 240-380 | 120-190 | 1500-1700 | 110×2 | 4140×2500×2700 |

| VSI5X9532 | 45 | 40 | 350-540 | 180-280 | 1300-1510 | 160×2 | 4560×2600×2900 |

| VSI5X1145 | 50 | 45 | 500-640 | 250-360 | 1100-1310 | 220×2 | 5000×2790×3320 |

| VSI5X1263 | 55 | 60 | 454-486 | 545-849 | 900-1200 | 315×2 | 5700×2980×4190 |

Directly contact us with your needs and get a solution in seconds!

E-mail: sales-zjks@zoomjo.cn

Tel: +86-371-87087999

Mobile: +86-15670952888

WhatsApp: +86-13938216895

TikTok

Copyright © Henan ZOOMJO MINING Machinery Co., Ltd. All Rights Reserved.