Jaw Crusher

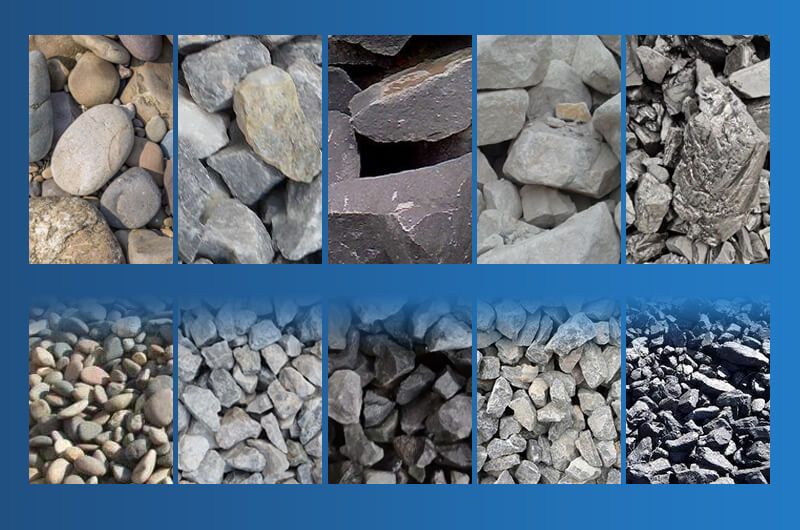

Applicable materials: river pebbles, granite, basalt, iron ore, limestone, quartz, coal gangue, construction waste, etc.

Applicable materials: river pebbles, granite, basalt, iron ore, limestone, quartz, coal gangue, construction waste, etc.

Jaw crusher is also called jaw crusher or jaw stone crusher. It is an early stone crushing equipment. It can be used for crushing various ores and large stones with a compressive strength of 147-245MPa, such as river pebbles, cobblestones, granite, and construction waste. It is often used as a coarse crushing equipment in some large-scale aggregate production lines and open-pit and underground mining operations.

Scope of application: large-block material crushing in mining, metallurgy, construction, highway, railway, water conservancy, chemical industry and other industries

Finished product specifications: 40-100mm 50-100mm 65-180mm 80-180mm

Unique flywheel design: effectively reduce vibration, stable machine operation.

Large crushing ratio: low suspension motion mechanism, large crushing ratio.

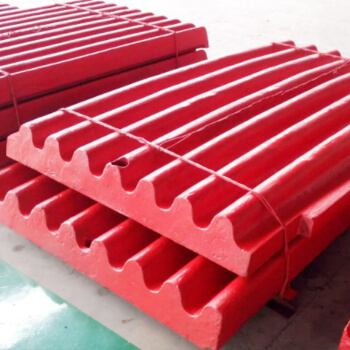

Easy maintenance: high wear-resistant tooth plate, long maintenance cycle, cost saving.

Low failure rate: reliable performance, optimized design, low failure rate.

The jaw crusher consists of several key components that work together to crush materials:

Fixed jaw

Fixed working surface constituting the crushing chamber

Made of high manganese steel and other wear-resistant materials

Remain still during the crushing process

Movable jaw plate

Also known as the swing jaw, it is the main moving part of the crusher

Adopts casting structure, reciprocating motion on fixed jaw plate

Directly apply crushing force to the material

Toggle plate (thrust plate)

Key components that control the motion trajectory of the jaw plate

Usually made of cast iron or high manganese steel

Adjust the jaw plate movement range to control the discharge particle size

Eccentric shaft

The core transmission component of the crusher bears huge bending force

Made of high carbon steel for durability and resistance to bending

Converts the rotational motion of the motor into reciprocating motion of the jaw plate

flywheel

Storing and releasing energy through inertia

Ensure smooth and continuous operation of the machine

Usually made of cast iron or cast steel

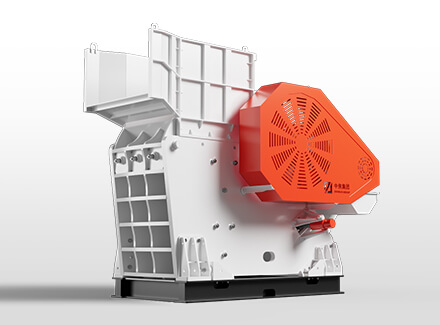

PE/PEX jaw crusher is an early type with simple structure. PE type is a coarse jaw crusher, and PEX type is a secondary jaw crusher. It is the main crushing equipment in the small stone production line.

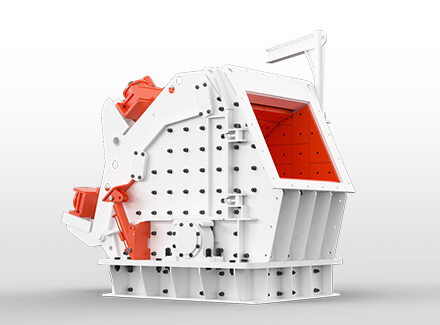

European version jaw crusher is developed by Zhongjiao combined with German crushing technology. The large inclination angle of the toggle plate enables higher output and more uniform particle size. It optimizes the crusher cavity and performs well in processing hard materials.

It consists of jaw crusher, vibrating feeder, screening equipment, conveying equipment, etc., becoming a walking coarse crushing production line. Its application saves the time spent on material transportation and production costs.

| Crusher equipment specification parameter table | ||||

|---|---|---|---|---|

| materials | Limestone (lower hardness) | |||

| Device Model | PE1200×1500 | |||

| Processing power | 800 tons/hour | |||

| Feed size | ≤1020mm | |||

| Finished product specifications | 0-10mm | 10-20mm | 20-40mm | 40-80mm |

| Multi-grade generation | ||||

This fixed production line successfully meets the customer's demand for limestone crushing, and the product particle size distribution meets the requirements.

| Model | Feeding Size(mm) | Discharge Size(mm) | Processing Capacity (t/h) | Motor Power(kw) | Overall Dimension(mm) |

|---|---|---|---|---|---|

| PE150×250 | ≤130 | 15-45 | 1-4 | 5.5 | 896×745×935 |

| PE250×300 | ≤150 | 15-55 | 3-6 | 7.5 | 1050×987×1000 |

| PE250×400 | ≤210 | 25-60 | 5-20 | 15 | 1215×1520×1030 |

| PE400×600 | ≤350 | 40-90 | 15-60 | 30 | 1650×1588×1050 |

| PE500×750 | ≤425 | 50-100 | 40-110 | 45 | 1956×1918×1920 |

| PE600×900 | ≤500 | 60-125 | 90-180 | 55 | 2250×2733×2280 |

| PE800×900 | ≤600 | 80-140 | 100-220 | 75 | 2450×2950×2490 |

| PE750×1060 | ≤630 | 60-150 | 110-380 | 110 | 2531×2455×2783 |

| PE900×1060 | ≤700 | 100-160 | 230-390 | 110 | 2900×2657×2950 |

| PE900×1200 | ≤750 | 110-165 | 220-450 | 132 | 3100×2760×3260 |

| PE1000×1200 | ≤900 | 110-185 | 315-500 | 132 | 3200×2760×3260 |

| PE1200×1500 | ≤950 | 115-195 | 550-1000 | 220 | 3710×3446×4075 |

| PE1500×1800 | ≤1200 | 135-225 | 600-1200 | 280 | 5100×4700×4300 |

| PEX150×750 | ≤120 | 10-40 | 8-25 | 15 | 1310×1118×1145 |

| PEX250×750 | ≤210 | 15-50 | 15-35 | 22 | 1400×1751×1515 |

| PEX350×750 | ≤300 | 15-50 | 18-40 | 30 | 1485×1680×1648 |

| PEX250×1000 | ≤210 | 15-60 | 15-60 | 30 | 1550×1964×1380 |

| PEX250×1200 | ≤210 | 15-60 | 20-60 | 37 | 1530×1946×1380 |

| PEX300×1300 | ≤250 | 25-60 | 16-105 | 55-75 | 2000×2320×1730 |

| PEX300×1500 | ≤250 | 25-60 | 18-122 | 15-90 | 2200×2320×1730 |

| PEX500×1500 | ≤425 | 50-100 | 50-220 | 90-110 | 2300×2420×1840 |

Consider the following:

Feed size: not exceeding the maximum allowable value of the equipment

Finished product requirements: Different models have different discharge ranges

Capacity requirements: Select by hourly processing volume

Material hardness: Hard materials require higher crushing force

By adjusting the jaw spacing:

Hydraulic adjustment system

Mechanical adjustment (shims or wedges)

Several customization options available:

Jaw plate material customization

Motor power adjustment

Special function installation

Regular inspection of wear parts

Keep it well lubricated

Tighten loose bolts

Clean equipment promptly

Directly contact us with your needs and get a solution in seconds!

E-mail: sales-zjks@zoomjo.cn

Tel: +86-371-87087999

Mobile: +86-15670952888

WhatsApp: +86-13938216895

TikTok

Copyright © Henan ZOOMJO MINING Machinery Co., Ltd. All Rights Reserved.