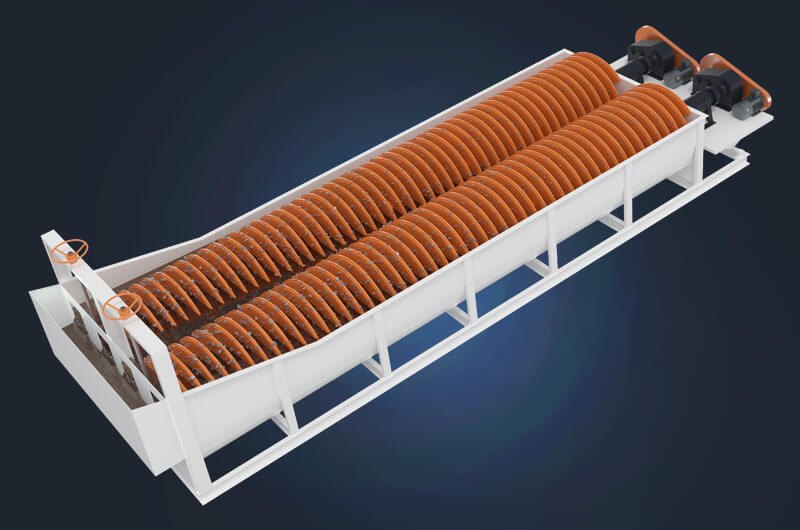

Spiral Classifier

Applicable materials: In the process of metal beneficiation, including gravity concentration and ore washing, such as quartz, gold ore, iron ore, copper ore, ore, slurry, fine mud, cement clinker, magnetite and other materials.

Applicable materials: In the process of metal beneficiation, including gravity concentration and ore washing, such as quartz, gold ore, iron ore, copper ore, ore, slurry, fine mud, cement clinker, magnetite and other materials.

Spiral classifier is one of the equipment for mineral processing. It is a kind of equipment for mechanical classification based on the principle that the solid particles have different specific gravities and therefore different precipitation speeds in liquid. Spiral classifier is used to process alluvial sand ore, especially for those with high dissociation degree of useful mineral monomers and flat shapes. Spiral classifier is referred to as classifier. There are four main types of classifiers: high weir single spiral and double spiral, submerged single spiral and double spiral.

In the process of metal beneficiation, including gravity concentration and ore washing, such as quartz, gold ore, iron ore, copper ore, ore, slurry, fine mud, cement clinker, magnetite and other materials.

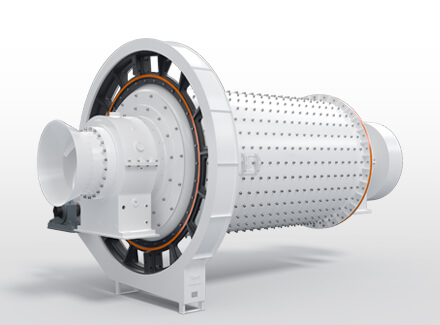

1. The spiral classifier is widely used in the ore dressing plant to form a closed-loop cycle with the ball mill to separate the ore sand, or to classify the ore sand and fine mud in the gravity ore dressing plant, and to classify the ore pulp in the metal ore dressing process, and to remove mud and water in the ore washing operation.

2. The spiral classifier adopts frequency conversion control technology, which is simpler to operate, tile lining, and the maintenance rate is very low.

3. The quality of stone powder is easy to control, and the fineness adjustment is convenient, flexible and reliable. The content of 0-0.75mm stone powder can be adjusted between 2%-15%.

| Model | Specification | Screw Diameter (mm) | Rotating Speed of Screw (r/min) | Cell | Production Capacity (t/24h) | Driving Motor | Hoist Motor | Weight (t) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Length (mm) | Width (mm) | Dip (°) | Model | Power (kw) | Model | Power (kw) | ||||||

| FG-5 | φ500 | 500 | 9.2 | 3900 | 560 | 14°-10.5° | 21-75 | Y132M-8 | 3 | Manual | - | 1.6 |

| FG-7 | φ750 | 750 | 7.8 | 5367 | 830 | 14°-10.5° | 65-154 | Y132M-8 | 3 | Manual | - | 2.9 |

| FG-10 | φ1000 | 1000 | 7 | 6500 | 1110 | 14°-10.5° | 85 | Y132M2-6 | 5.5 | Manual | - | 4.5 |

| FG-12 | φ1200 | 1200 | 5,6,7 | 6500 | 1372 | 14°-10.5° | 150 | Y132M2-6 | 5.5 | XWD4-29-2.2 | 2.2 | 8.8 |

| FG-15 | φ1500 | 1500 | 2.5,4,6 | 8265 | 1664 | 14°-18.5° | 235 | Y160M-6 | 7.5 | XWD4-29-2.2 | 2.2 | 11.7 |

| FG-20 | φ2000 | 2000 | 5.4 | 8400 | 2396 | 14.5°-18.5° | 400 | Y160L-4 | 15 | XWD4-29-2.2 | 2.2 | 20.5 |

| FG-24 | φ2400 | 2400 | 3.6,5.4,6.3 | 9160 | 2600 | 14°-18.5° | 580 | Y160L-6/4 | 11/15 | XWD4-29-22 | 2.2 | 26.7 |

| FG-30 | φ3000 | 3000 | 3.17 | 12500 | 3200 | 14°-18.5° | 890 | Y180L-4 | 22 | Y112M-4 | 4 | 44.88 |

| FG-35 | φ3500 | 3500 | 2.85 | 14000 | 3650 | 16°-18.5° | 1300 | Y225S-4 | 37 | Y112M-4 | 4 | 62 |

| Model | Specification | Screw Diameter (mm) | Rotating Speed of Screw (r/min) | Cell | Production Capacity (t/24h) | Driving Motor | Hoist Motor | Weight (t) | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Length×Width (mm) | Dip (°) | Model | Power (kw) | Model | Power (kw) | ||||||

| 2FG-12 | φ1200 | 1200 | 5,6,7 | 6500×2620 | 14°-10.5° | 300 | Y132M2-6 | 5.5×2 | XWD4-29-2.2 | 2.2×2 | 15.8 |

| 2FG-15 | φ1500 | 1500 | 2.5,4,6 | 8265×3200 | 14°-18.5° | 460 | Y160M-6 | 7.5×2 | XWD4-29-2.2 | 2.2×2 | 22.1 |

| 2FG-20 | φ2000 | 2000 | 5.4 | 8400×4296 | 14.5°-18.5° | 800 | Y160L-4 | 15×2 | XWD4-29-2.2 | 2.2×2 | 36.4 |

| 2FG-24 | φ2400 | 2400 | 3.6,5.4,8.3 | 9160×5040 | 14°-18.5° | 1160 | Y160L-6/4 | 11×2 15×2 | XWD4-29-2.2 | 2.2×2 | 45.9 |

| 2FG-30 | φ3000 | 3000 | 3.17 | 12500×6300 | 14°-18.5° | 1785 | Y180L-4 | 22×2 | Y112M-4 | 4×2 | 77.08 |

| 2FG-35 | φ3500 | 3500 | 2.85 | 14000×7300 | 16°-18.5° | 25800 | Y225S-4 | 37×2 | Y112M-4 | 4×2 | 113.5 |

| Model | Specification | Screw Diameter (mm) | Rotating Speed of Screw (r/min) | Cell | Production Capacity (t/24h) | Driving Motor | Hoist Motor | Weight (t) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Length (mm) | Width (mm) | Dip (°) | Model | Power (kw) | Model | Power (kw) | ||||||

| FC-10 | φ1000 | 1000 | 6-7.4 | 6500 | 1110 | 14°-10.5° | 75 | Y132M2-6 | 5.5 | Manual | - | 6 |

| FC-12 | φ1200 | 1200 | 5,6,7 | 8400 | 1372 | 14°-10.5° | 120 | Y160M-6 | 7.5 | XWD4-29-2.2 | 2.2 | 11 |

| FC-15 | φ1500 | 1500 | 2.5,4,6 | 10500 | 1664 | 14°-18.5° | 185 | Y160M-6 | 7.5 | XWD4-29-22 | 2.2 | 15.3 |

| FC-20 | φ2000 | 2000 | 5.4 | 12800 | 2396 | 14.5°-18.5° | 400 | Y180M-4 | 18.5 | XWD4-29-2.2 | 2.2 | 29 |

| FC-24 | φ2400 | 2400 | 3.6 | 11130 | 2600 | 14°-18.5° | 455 | Y200L1-6 | 18.5 | XWD4-29-2.2 | 2.2 | 37 |

| FC-30 | φ3000 | 3000 | 3.2 | 14300 | 3200 | 14°-18.5° | 705 | Y200L-4 | 30 | Y112M-4 | 4 | 43.5 |

| Model | Specification | Screw Diameter (mm) | Rotating Speed of Screw (r/min) | Cell | Production Capacity (t/24h) | Driving Motor | Hoist Motor | Weight (t) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Length (mm) | Width (mm) | Dip (°) | Model | Power (kw) | Model | Power (kw) | ||||||

| 2FC-12 | φ1200 | 1200 | 6 | 8400 | 2620 | 14°-10.5° | 240 | Y160M-6 | 7.5×2 | XWD4-29-22 | 2.2×2 | 19.6 |

| 2FC-15 | φ1500 | 1500 | 2.5,4,6 | 10500 | 3200 | 14°-18.5° | 370 | Y160M-6 | 7.5×2 | XWD4-29-2.2 | 2.2×2 | 27.5 |

| 2FC-20 | φ2000 | 2000 | 5.4 | 12800 | 4280 | 14.5°-18.5° | 640 | Y180M-4 | 18.5×2 | XWD4-29-22 | 2.2×2 | 50 |

| 2FC-24 | φ2400 | 2400 | 3.6 | 11160 | 5040 | 14°-18.5° | 910 | Y200L1-6 | 18.5×2 | XWD4-29-22 | 2.2×2 | 65.3 |

| 2FC-30 | φ3000 | 3000 | 3.17 | 14300 | 6300 | 14°-18.5° | 1410 | Y200L-4 | 30×2 | Y112M-4 | 4×2 | 84.9 |

Directly contact us with your needs and get a solution in seconds!

E-mail: sales-zjks@zoomjo.cn

Tel: +86-371-87087999

Mobile: +86-15670952888

WhatsApp: +86-13938216895

TikTok

Copyright © Henan ZOOMJO MINING Machinery Co., Ltd. All Rights Reserved.