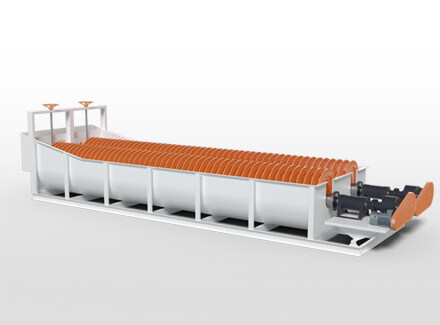

Spiral chute

Applicable materials: iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten ore, tin ore, niobium ore, etc.

Applicable materials: iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten ore, tin ore, niobium ore, etc.

The spiral chute, also known as the mineral spiral separator, is a gravity separation equipment. It uses the inertial centrifugal force generated by the slurry in the spiral rotation motion to separate light minerals from heavy minerals.

The spiral chute combines the characteristics of the spiral concentrator, vibrating table and centrifugal concentrator. It is the best equipment for mining and mineral processing, especially for sand mining along the coast, riverside, beach and stream.

iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten ore, tin ore, niobium ore, etc.

Spiral chute can be used to separate fine-grained minerals with different specific gravities and a particle size of 0.3-0.02 mm. Applicable materials Gold placer iron ore magnetite, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten ore, tin ore, tantalum ore, niobium ore, antimony ore and other non-ferrous metals, rare metals, non-metallic minerals.

1. Reasonable structure, simple installation, light weight, small footprint, easy operation.

2. Stable ore dressing and clear ore separation.

3. Large processing capacity, high efficiency, high ore dressing enrichment ratio, high recovery rate, and reliable operation.

4. Moisture-proof, rust-proof, corrosion-resistant, strong adaptability to fluctuations in feed volume, concentration, particle size, and grade, and no noise.

The upper part of the spiral chute component has a distributor and a feed chute, and the lower part has a product interceptor and a collection chute. The entire device adopts a steel frame vertical frame.

The spiral chute is similar to the shape of a screw thread. The movement of the material inside can be divided into three stages: the material introduction stage, the material acceleration stage, and the material uniform speed warehouse stage. The third stage lasts the longest and is the key to material crushing.

The main part of the spiral chute device is the spiral scraper, which is made of glass fiber reinforced plastic. The inner surface of the spiral chute is coated with a wear-resistant lining, usually a polyurethane wear-resistant glue or epoxy resin mixed with artificial corundum.

| Model | Capacity (t/h) |

|---|---|

| DL2000 | 15-40 |

| DL1500 | 8-16 |

| LL1200 | 4-6 |

| LL900 | 2-3 |

Directly contact us with your needs and get a solution in seconds!

E-mail: sales-zjks@zoomjo.cn

Tel: +86-371-87087999

Mobile: +86-15670952888

WhatsApp: +86-13938216895

TikTok

Copyright © Henan ZOOMJO MINING Machinery Co., Ltd. All Rights Reserved.