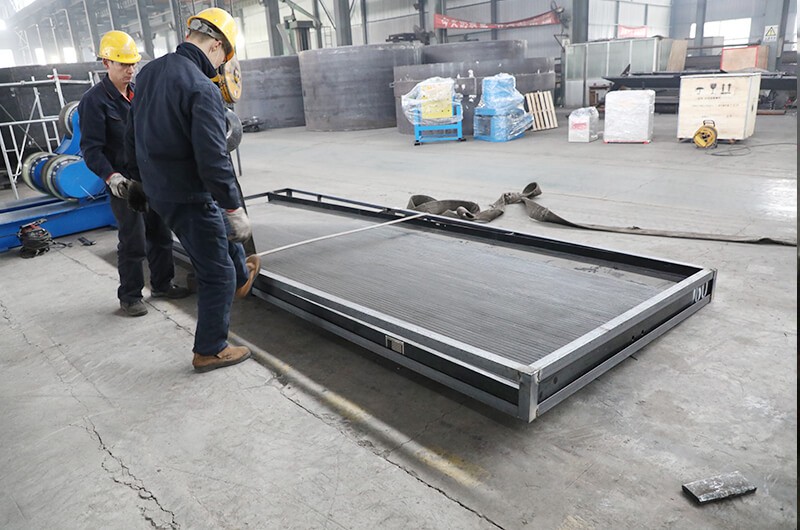

Shaker tables

Applicable materials: tin, tungsten, gold, silver, lead, zinc, tantalum, niobium, iron, manganese, titanium and coal, etc.

Applicable materials: tin, tungsten, gold, silver, lead, zinc, tantalum, niobium, iron, manganese, titanium and coal, etc.

The shaking table is mainly used to separate and recover rare metals and precious metal ores such as gold, iron, manganese, copper, chromium, tungsten, molybdenum, tin, tantalum, niobium, etc.

In addition, it can separate coal and purify non-metallic minerals such as talc, limestone, garnet and pyrophyllite. It can also be used to process non-ferrous metal ores before flotation.

The ZOOMJO GROUP shaking table can be used for coarse grinding, concentration and sweeping to separate coarse sand (2-0.5 mm), fine sand (0.5-0.074 mm), sludge (within 0.074 mm) and other particles of different particle sizes. It is very effective for selecting fine-grained materials below 1 mm, especially materials below 0.1 mm.

1. It has the advantages of high enrichment ratio, good separation efficiency and simple operation.

2. The finished product has good effect and can obtain the final concentrate and final tailings at one time.

3. Compared with traditional processes, it has the advantages of no need for chemicals, low energy consumption and easy management.

4. The price is favorable and has a high cost performance.

Unlike other bed surfaces on the market, ZOOMJO GROUP shaking tables are designed to withstand the harsh conditions of the mining industry. The bed surface is made of a steel frame wrapped in polyurethane fiberglass reinforced plastics (FRP). And the working surface is a special wear-resistant layer.

Along the longitudinal direction, there are many parallel bed bars or grooves on the bed surface. ZOOMJO GROUP shaking tables can be divided into three types: rectangular bed bars for coarse sand, trapezoidal bed bars for fine sand and grooved bed bars for sludge.

There is a feeding trough on the upper right side of the bed surface, which is about 1/3-1/4 of the total length. There are many small holes on one side of the feeding trough so that the slurry can be evenly distributed on the bed surface.

Connected to the feeding trough is the flushing trough, which occupies 2/3-3/4 of the total length of the bed surface. There are many small holes on the side of the water tank so that the flushing water can be evenly injected along the longitudinal direction of the bed.

The driving head of the vibration table is driven by an electric motor and connected to the bed surface through a pull rod, so that the bed surface reciprocates asymmetrically in the longitudinal direction.

When the bed surface moves forward, its speed increases from slow to fast, and then stops quickly.

When the bed surface moves backward, its speed increases rapidly from zero to the maximum value, and then slowly decreases to zero.

The support method of the bed surface can be divided into sitting type or suspended type.

Sitting type means that the bed surface is directly connected to the bracket, and a slope adjustment device is installed on the bracket to adjust the horizontal slope of the bed surface.

Suspension type means that the bed surface is suspended on the bracket with a wire rope. The bed surface is suspended in the air, and its slope is adjusted by adjusting the tightness of the wire rope.

| Name | Coarse sand shaker | Fine sand shaker | Slime Shaker | |

|---|---|---|---|---|

| Bed size | Length (mm) | 4450 | 4450 | 4450 |

| Transmission end width(mm) | 1855 | 1855 | 1855 | |

| Concentrate end width(mm) | 1546 | 1546 | 1546 | |

| Maximum feed size(mm) | 2 | 0.5 | 0.15 | |

| Feeding amount(t/d) | 30-60 | 10-20 | 15-25 | |

| Feed concentration(%) | 25-30 | 20-25 | 15-25 | |

| Route (mm) | 16-22 | 11-16 | 8-16 | |

| Frequency (f) | 45-48 | 48-53 | 50-57 | |

| Bed surface cleaning water volume(t/d) | 80-150 | 30-60 | 10-17 | |

| Horizontal slope of bed surface(°) | 2.5-4.5 | 1.5-3.5 | 1-2 | |

| Longitudinal slope of bed surface(%) | 1.4 | 0.92 | ---- | |

| Bed surface angle(°) | 32-42 | 40 | 42 | |

| Mineral processing area(㎡) | 7.6 | 7.6 | 7.6 | |

| Bed length ratio | 2.6 | 2.6 | 2.6 | |

| Bed end shape | Rectangle | Zigzag | Triangle | |

| Motor power(kw) | 1.1 | 1.1 | 1.1 | |

| Transmission mechanism | Eccentric connecting rod mechanism | |||

Directly contact us with your needs and get a solution in seconds!

E-mail: sales-zjks@zoomjo.cn

Tel: +86-371-87087999

Mobile: +86-15670952888

WhatsApp: +86-13938216895

TikTok

Copyright © Henan ZOOMJO MINING Machinery Co., Ltd. All Rights Reserved.