Rod mill

Applicable materials: quartz, iron ore, copper ore, gold ore, glass, construction waste, cement clinker, etc.

Applicable materials: quartz, iron ore, copper ore, gold ore, glass, construction waste, cement clinker, etc.

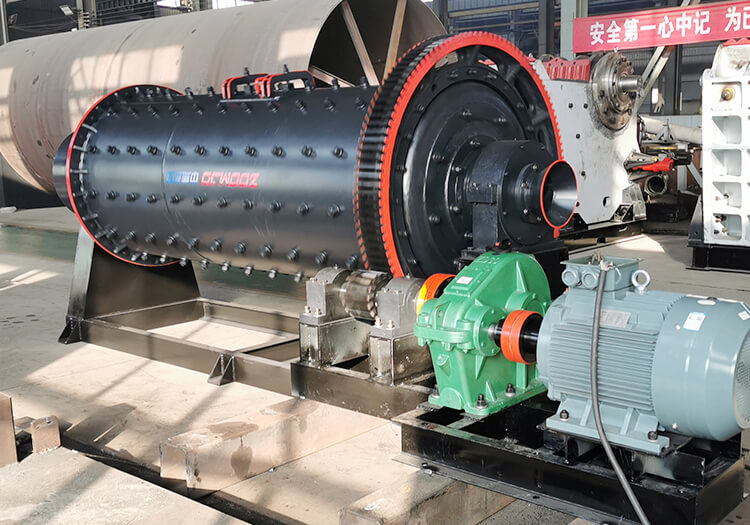

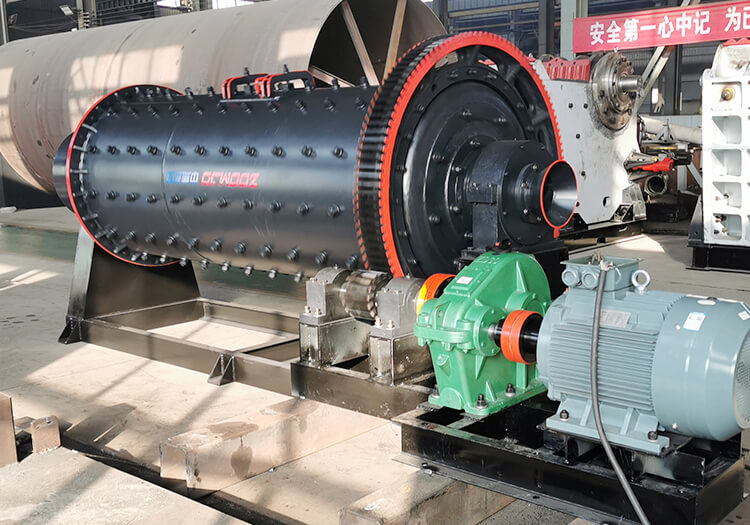

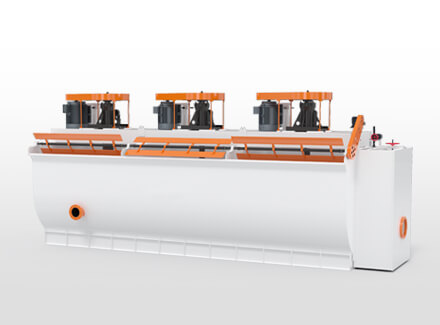

Rod mill is a grinding equipment that uses steel rods as grinding media. This mill produced by Zhongjiao adopts advanced controllable feeding and discharging technology. By combining the actual grinding materials and matching the appropriate grinding bodies, the traditional surface contact is changed to line contact, making the discharge particle size more uniform and the output higher.

Note: Rod mills are available in two forms: dry and wet. Users can choose according to their actual situation.

Applicable materials

quartz, iron ore, copper ore, gold ore, glass, construction waste, cement clinker, etc.

Grinding operations in industries such as refractory materials, chemicals, metallurgy, and glass that require relatively high uniformity of the finished product after grinding. In recent years, it has also been used in the sand making industry for construction sand, etc.

During the movement, the material is screened, large particles are lifted to the top of each layer, and concentrated to the place with strong crushing capacity. Therefore, the rod mill has high working efficiency and low power consumption.

When the ore is ground by steel bars, it is first crushed into coarse particles and then ground into smaller particles, which reduces the risk of over-crushing

Rod mill changes the surface contact of traditional ball mill to line contact.

When the rods rotate and rise with the liner, coarse particles are sandwiched between them, allowing fine particles to pass through the gaps of the rods, which is conducive to crushing coarse particles, so the coarse particles are concentrated where the grinding media hits.

Therefore, the rod mill product is more uniform and the over-crushing is lighter. It is suitable for ores of different hardness (Mohs hardness 5.5-2).

The particle size of the material produced by the rod mill can be adjusted according to the needs of the user, because there is a fineness control device and a screening device for discharge inside the rod mill. These two devices work at the same time.

Smaller mineral particles can be obtained by adjusting their size, so the size of the grinding particles can be effectively guaranteed.

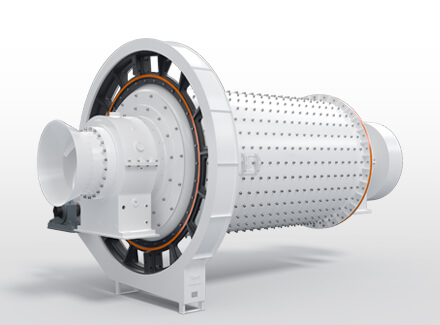

The rod mill adopts the reducer drive mode and centralized unloading. It mainly consists of the following parts:

The feeding device is a shoe-shaped hopper with an upper flange connected to the feeding device to receive the feed. There is an inspection door on the rear wall of the hopper, which forms a round tube and extends into a spiral barrel mounted on a hollow shaft, through which the material enters the mill.

The rotating part is a cylinder made of rolled and welded steel plates. A liner is provided inside the cylinder, which not only protects the cylinder but also lifts the steel rod to a suitable height, thereby improving the efficiency of sand making. There is an acid-resistant and alkali-resistant rubber pad between the steel liner and the simplified end cover to reduce noise and vibration.

The large and small gears are driven by helical gears, which are balanced in operation, have little impact and long service life. The use of spray lubrication and regular oiling reduces the labor intensity of workers, has good lubrication effect and reduces the consumption of lubricating oil.

The main bearing supports all the weight of rotating parts, steel bars, materials, etc. The bearing bushing is supported on a spherical seat, which can play a self-defense function and adapt to manufacturing and installation errors.

After the main bearing works for a long time, the bearing shell will wear and cause the hollow shaft to sink. The seal bracket can be adjusted downward to ensure good contact between the seal and the hollow shaft.

| Model | Cylinder Specifications(mm) | Cylinder speed(r/min) | Feed size(mm | Discharge size(mm) | Capacity (t/h) | Power (kw) | Total weight(t) | |

|---|---|---|---|---|---|---|---|---|

| Diameter | Length | |||||||

| MBS0918 | 900 | 1800 | 36-38 | ≤25 | 0.833-0.147 | 0.62-3.2 | 18.5 | 5.9 |

| MBS0924 | 900 | 2400 | 36 | ≤25 | 0.833-0.147 | 0.81-4.3 | 22 | 6.7 |

| MBS1224 | 1200 | 2400 | 36 | ≤25 | 0.833-0.147 | 1.1-4.9 | 30 | 13.9 |

| MBS1530 | 1500 | 3000 | 29.7 | ≤25 | 0.833-0.147 | 2.4-7.5 | 75 | 19.8 |

| MBS1830 | 1830 | 3000 | 25.4 | ≤25 | 0.833-0.147 | 4.8-11.6 | 130 | 34.9 |

| MBS2130 | 2100 | 3000 | 23.7 | ≤25 | 0.833-0.147 | 14-35 | 155 | 46.5 |

| MBS2136 | 2100 | 3600 | 23.7 | ≤25 | 0.833-0.147 | 19-43 | 180 | 48.7 |

| MBS2430 | 2400 | 3000 | 21 | ≤50 | 0.833-0.147 | 25-65 | 245 | 59.7 |

| MBS2736 | 2700 | 3600 | 20.7 | ≤50 | 0.833-0.147 | 32-86 | 380 | 92.5 |

| MBS2740 | 2700 | 4000 | 20.7 | ≤50 | 0.833-0.147 | 32-92 | 400 | 95 |

| MBS3245 | 3200 | 4500 | 18 | ≤50 | 0.833-0.147 | 64-180 | 630 | 149 |

Directly contact us with your needs and get a solution in seconds!

E-mail: sales-zjks@zoomjo.cn

Tel: +86-371-87087999

Mobile: +86-15670952888

WhatsApp: +86-13938216895

TikTok

Copyright © Henan ZOOMJO MINING Machinery Co., Ltd. All Rights Reserved.