Ceramic ball mill

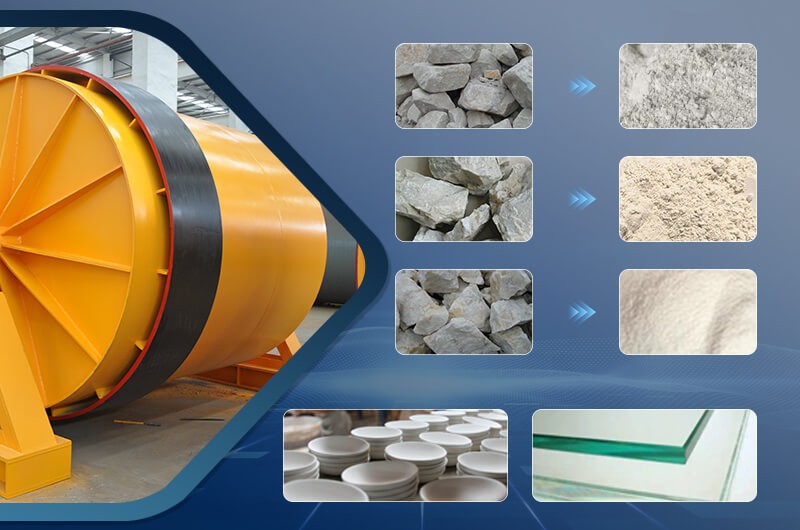

Applicable materials: cement, silicate, new building materials, fertilizers, ferrous and non-ferrous metal beneficiation, glass, ceramics, etc.

Applicable materials: cement, silicate, new building materials, fertilizers, ferrous and non-ferrous metal beneficiation, glass, ceramics, etc.

Ceramic ball mill is mainly used for mixing and grinding materials. The fineness of the product is uniform and it saves power. It can be dry or wet. The machine can use different lining types according to production needs to meet different needs. The fineness of the grinding operation is controlled by the grinding time. The electric ball mill starts with auto-coupling decompression to reduce the starting current. Its structure is divided into integral type and independent type. This product has the characteristics of low investment, lower energy consumption than similar products, novel structure, simple operation, safe use, stable and reliable performance, etc.

cement, silicate, new building materials, fertilizers, ferrous and non-ferrous metal beneficiation, glass, ceramics, etc.

Compared with ceramic liners made of high manganese steel, ceramic liners have the following advantages:

Prevent iron contamination, especially suitable for grinding glass, ceramics and other materials.

Wear resistance: The hardness exceeds HRA85, which is 271.5 times harder than high manganese steel.

High temperature resistance: It can operate for a long time at temperatures from 0°C to 250°C.

Reduce costs: Excellent wear resistance reduces maintenance frequency, saving maintenance and labor costs.

More obvious advantages exist in the grinding of materials with higher requirements on material iron content and cleanliness.

Ceramic grinding balls are white balls with a diameter of 0.5 mm to 120 mm. They consist of 90% aluminum. Therefore, ceramic balls are also called aluminum balls.

Full range of spare parts inventory: covering the core components of the ball mill (housing, lubrication system, filter, etc.), ensuring rapid response to urgent needs.

Extremely fast delivery: global supply chain support, shortening downtime waiting time.

Standardized inspection: Regularly inspect key components (such as trunnion bushings and transmission systems) to prevent sudden failures and reduce maintenance costs.

Optimization and adjustment: Dynamically calibrate equipment parameters to ensure efficient and stable operation and extend service life.

Accurate planning: Combine tool management and time-motion analysis to optimize downtime processes and reduce production losses.

Safe execution: Professional teams control the entire process to ensure that maintenance is completed efficiently, safely and on time.

Graded maintenance services: From partial renovation to complete machine transformation, targeted restoration of equipment performance.

Aging management: Optimize maintenance strategies based on wear analysis to improve long-term operating reliability.

| Model | Cylinder size(mm) | Speed (r/min) | Capacity (t/h) | Feed size (mm) | Output size (mm) | Output (t/h) | Motor | Weights (t) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Diameter | Length | Model | Power(kw) | |||||||

| YMQG900x1800 | 900 | 1800 | 38 | 1.8 | 0-25 | 0.075-0.6 | 0.44-2.4 | Y180L-6 | 15 | 4.2 |

| YMQG900x3000 | 900 | 3000 | 38 | 2.5 | 0-25 | 0.075-0.6 | 0.7-2.9 | Y180L-6 | 18.5 | 5.4 |

| YMQG1200x2400 | 1200 | 2400 | 37 | 4.8 | 0-25 | 0.075-0.6 | 0.4-5.8 | Y225M-6 | 30 | 8.2 |

| YMQG1200x4500 | 1200 | 4500 | 37 | 5.2 | 0-25 | 0.075-0.6 | 1.4-5 | Y280M-6 | 55 | 11 |

| YMQG1500x3000 | 1500 | 3000 | 29 | 10 | 0-25 | 0.075-0.4 | 2.8-9 | Y315S-6 | 75 | 16.3 |

| YMQG1500x5700 | 1500 | 5700 | 29 | 12 | 0-25 | 0.075-0.4 | 3.1-7 | Y315M-6 | 90 | 20.7 |

| YMQG1830x6400 | 1830 | 6400 | 23.9 | 18.5 | 0-25 | 0.075-0.4 | 6-8.5 | JR138-8 | 210 | 35.1 |

| YMQG1830x7000 | 1830 | 7000 | 23.9 | 21 | 0-25 | 0.075-0.4 | 6-7 | JR138-8 | 245 | 38 |

Directly contact us with your needs and get a solution in seconds!

E-mail: sales-zjks@zoomjo.cn

Tel: +86-371-87087999

Mobile: +86-15670952888

WhatsApp: +86-13938216895

TikTok

Copyright © Henan ZOOMJO MINING Machinery Co., Ltd. All Rights Reserved.