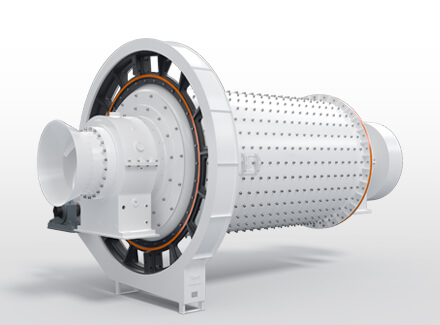

Product Introduction

Raymond mill, also known as Raymond machine, is an indispensable equipment for the powder industry for grinding non-metallic ores. ZOOMJO GROUP adopts new structural technology and is designed based on the traditional Raymond mill. It has high efficiency, low power consumption, small footprint, and small one-time investment. It is widely used in limestone, potassium feldspar, bentonite, kaolin, cement, gypsum, glass, etc., with Mohs hardness not greater than 9.3, moisture below 6%, non-flammable and explosive minerals, chemicals, construction and other industries. More than 280 kinds of materials are processed in fine powder. The finished particle size of the Raymond mill can be adjusted arbitrarily within the range of 80-325 mesh, and some materials can reach 600 mesh.

Applicable materials

gypsum, talc, calcite, limestone, marble, feldspar, barite, dolomite, granite, kaolin, bentonite, medical stone, bauxite, red iron oxide, iron ore, etc. The finished product fineness is between 613 microns and 440 microns (0.613 mm-0.044 mm)

Application scope

Suitable for small and medium-sized mining, chemical industry, building materials, metallurgy, refractory materials, glass, cement and other industries.

Product advantages

1. Convenient transportation and installation: The new structural design makes it occupy a smaller space, and it is more convenient to transport, install, operate and maintain.

2. High efficiency and less pollution: Raymond mill adopts PLC electrical automation control, which effectively reduces the failure rate and labor cost, while achieving high production, low noise and less pollution.

3. Fineness can be adjusted arbitrarily: The grinding fineness can be adjusted arbitrarily between 80-800 mesh, and the applicability is more flexible and extensive.

4. Long parts replacement cycle: The grinding roller and grinding ring have a long service life, eliminating the disadvantage of short replacement cycle of wearing parts of centrifugal mill.

Accessories Introduction

Raymond mill is mainly composed of grinding roller, grinding ring, star rack, scraper blade, blower, classifier, reducer and air collector.

1. Grinding rollers

Grinding rollers are the parts that grind materials. Usually 3-6 grinding rollers are used, and they rotate around the grinding ring. As the wearing parts of Raymond mill, it adopts more wear-resistant alloy steel or high-quality alloy carbon steel.

2. Grinding Ring

The grinding ring is a fixed part located below the grinding roller. The material is ground between the grinding roller and the grinding ring. The grinding ring is made of manganese alloy steel and is suitable for soft or low hardness materials.

3. star rack

When the mill is running, the main shaft drives the star rack to realize the rotation of the grinding roller and grinding ring.

4. scraper blade

The material is scooped up and moved forward along the grinding ring at high speed, and then thrown into the gap between the grinding roller and the grinding ring to complete the grinding process. The scraper blade is made of wear-resistant alloy material.

5. Blower

The blower generates airflow to blow the ground powder to the upper classifier for classification.

6. Classifier

The classifier is used to classify the ground powder by particle size. The rotation speed controls the fineness of the product. The fine powder is collected by the cyclone separator, while the coarse powder is returned for re-grinding.

7. Speed reducer

The gearbox can reduce the speed of the motor, thereby obtaining a power transmission mechanism with greater torque.

8. Air Collector

The powder is separated from the air and falls from the discharge port, while the air with fine particles enters the dust collector and is discharged after being processed.

Product Parameters

| Model | ZRM100 | ZRM130 | ZRM160 |

|---|

| Number of grinding rollers (pieces) | 4 | 5 | 6 |

| Grinding roller diameter x height (mm) | Ф310x170 | Ф410x210 | Ф440x270 |

| Grinding ring diameter x height (mm) | Ф950x170 | Ф1280x210 | Ф1600x270 |

| Main engine speed (r/min) | 130 | 103 | 82 |

| Maximum feed particle size (mm) | ≤25 | ≤30 | ≤35 |

| Finished product particle size (mm) | 1.6-0.045(Fine powder can reach 0.038) | 1.6-0.045(Fine powder can reach0.038) | 1.6-0.045(Fine powder can reach 0.038) |

| Capacity (t/h) | 3.0-8.0 | 6.0-11.0 | 9.0-22.0 |

| Overall dimensions length x width x height (mm) | 7100x5900x7900 | 9200x7250x9700 | 12550x5700x8355 |

| Main engine motor model | Y225S-4 | Y280S-4 | Y315M-4 |

| Main engine motor power (kW) | 37 | 75 | 132 |

| Powder selector motor model | YCT200-4A | YCT200-4B | YCT250-4A |

| Powder selector motor power (kW) | 5.5 | 7.5 | 18.5 |

| Draught fan motor model | Y225S-4 | Y280S-4 | Y315M-4/Y315L1-4 |

| Draught fan motor power (kW) | 37 | 75 | 132/160 |

| Electromagnetic vibrating feeder model | GZ2F | GZ3F | GZ3F |

| Electromagnetic vibrating feeder power (kW) | 0.15 | 0.2 | 0.2 |

English

English

中文

中文