Rotary Dryer

Applicable materials: various metal ores, mineral powder, coal powder, sand

Applicable materials: various metal ores, mineral powder, coal powder, sand

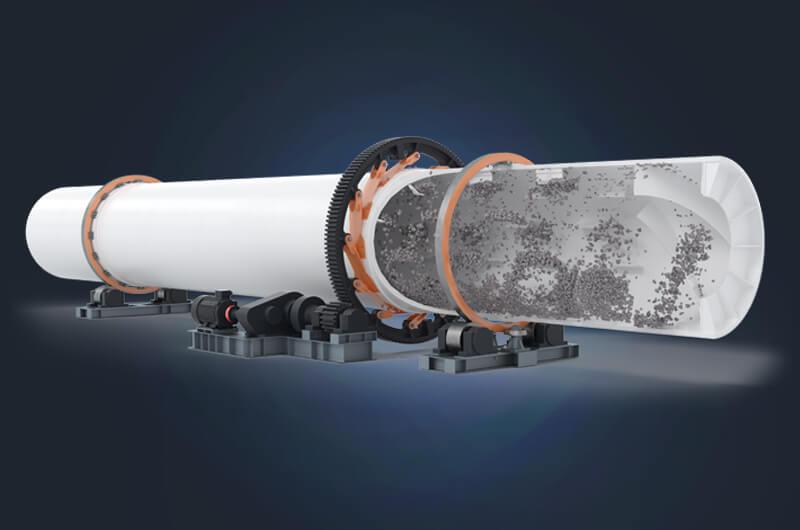

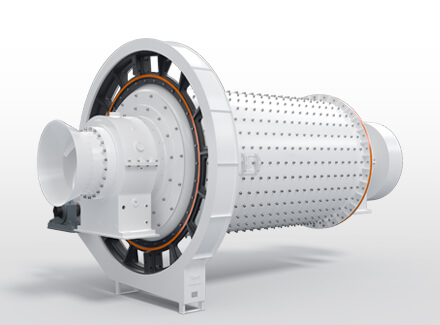

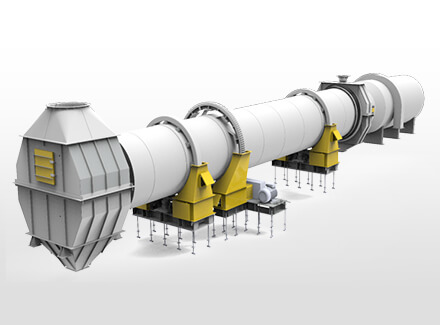

Rotary dryer also called dryer, is mainly used in mineral processing, building materials, metallurgy, chemical industry and other sectors to dry materials with a certain humidity. The dryer equipment has strong adaptability to materials, can dry all kinds of materials, and the equipment is simple and reliable operation, so it is commonly used.

The dryer is an efficient and multifunctional drying equipment with an operating temperature of up to 800°C. It can reduce the moisture content of various materials to 0.5%-1% and is widely used in many industries.

• Natural sand: river sand, yellow sand, sea sand, etc. • Machine-made sand: silica sand, quartz sand, glass sand, dolomite sand • Others: aggregate, cement, clay, blast furnace slag, gypsum powder, etc.

• Agricultural by-products: sawdust, wood chips, straw, alfalfa, bagasse

• Food processing waste: wine lees, wine lees, potato lees, fruit lees

• Organic fertilizers: animal manure, eggshells, shells, cattle bones, etc.

• Industrial waste: slag, steel slag, fly ash, industrial sludge

• Chemical products: phosphate, barium chloride, ammonium nitrate, ammonium sulfate

• Others: petroleum coke, desulfurized gypsum, calcium carbonate, activated lime

• Various mining products

• Coal and its by-products

Adopting high-temperature flue gas rapid evaporation technology, the thermal efficiency is up to 80%.

Continuous operation capacity of 1.9-76 tons/hour, the output can be flexibly adjusted.

Significantly reduce drying costs, low fuel consumption, economical and efficient operation.

Special design effectively prevents sticky materials from sticking to the wall

The final product parameters can be precisely controlled:

• Adjustable moisture content (e.g. coal can be dried to 8% moisture content)

• Controllable particle size (e.g. 8mm specification products can be produced)

Rugged structural design with high overload capacity

Stable and reliable operation with low maintenance requirements

Intelligent temperature control system to maintain a balanced drum temperature

Equipped with advanced dust removal device, realizing zero emission of dust.

Exhaust gas purification treatment, mainly converted into water vapor emissions

| Specification(m)(diameter x length) | Cylinder volume (m³) | Production capacity (t/h) | Installation slope (%) | Maximum intake air temperature (°C) | Main motor (kw) | Total weight (t) |

| Φ1.2×8.0 | 9.0 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

| Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

| Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

| Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

| Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

| Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

| Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

| Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

| Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |

Directly contact us with your needs and get a solution in seconds!

E-mail: sales-zjks@zoomjo.cn

Tel: +86-371-87087999

Mobile: +86-15670952888

WhatsApp: +86-13938216895

TikTok

Copyright © Henan ZOOMJO MINING Machinery Co., Ltd. All Rights Reserved.