Magnetic separator

Applicable materials: magnetite, pyrrhotite, roasted ore, ilmenite, coal, non-metallic minerals, etc. Applications: Widely used in industries such as mining and minerals, aggregates, coal, recycling and building materials

Applicable materials: magnetite, pyrrhotite, roasted ore, ilmenite, coal, non-metallic minerals, etc. Applications: Widely used in industries such as mining and minerals, aggregates, coal, recycling and building materials

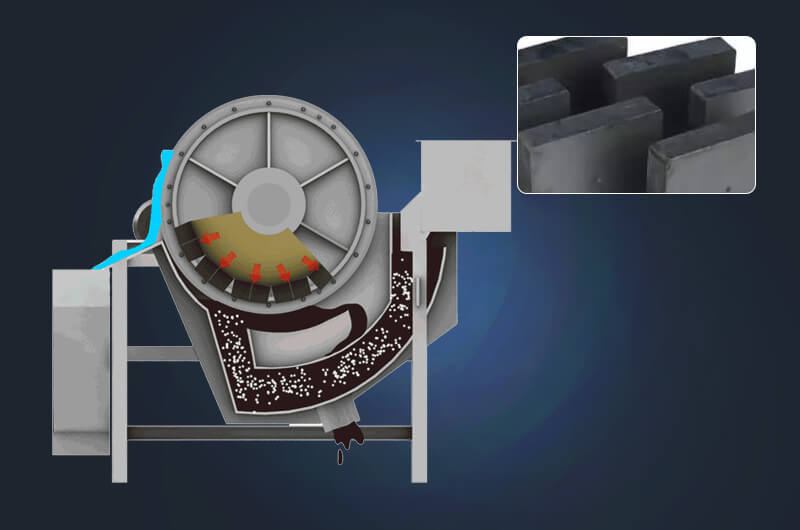

The magnetic separator is suitable for wet magnetic separation of magnetite, pyrrhotite, roasted ore, ilmenite and other materials with a particle size below 3mm. It is also used for iron removal of coal, non-metallic minerals, building materials and other materials. The magnetic system of the magnetic separator is made of high-quality ferrite materials or composited with rare earth magnets. The average magnetic induction intensity of the cylinder surface is 100-600mT. According to user needs, magnetic separation with different surface strengths such as downstream, semi-countercurrent and countercurrent can be provided. ZOOMJO GROUP magnetic separation equipment has the advantages of simple structure, large processing capacity, convenient operation and easy maintenance.

magnetite, pyrrhotite, roasted ore, ilmenite, coal, non-metallic minerals, etc.

Widely used in industries such as mining and minerals, aggregates, coal, recycling and building materials

According to the dry or wet processing method in mineral separation, it is divided into two types: :dry magnetic separator and wet magnetic separator。

Dry magnetic separators are ideal for roughing or primary separation and are typically used to separate large particles of strongly magnetic ores from fine, weakly magnetic ores.

Water-saving and environmentally friendly: No water source is required, reducing wastewater problems, suitable for areas with limited water resources.

Low maintenance: Simple structure, few parts, low failure rate, and reduced maintenance costs.

Easy to move: Compact and lightweight, easy to install and reposition.

Low energy consumption: Generally consumes less energy than wet magnetic separation.

Wet magnetic separators are often used to separate fine strong magnetic ores from fine weak magnetic ores, effectively improving the recovery rate of fine and powdery materials.

High separation efficiency: Wet magnetic separators are generally more efficient than dry magnetic separators, especially for fine, weakly magnetic and clay-rich minerals such as hematite and magnetite.

Suitable for wet materials: Wet separators can handle wet materials without additional drying.

High-grade concentrate: The full magnetic design increases the contact area between the slurry and the working surface, thereby extending the separation time and increasing the concentrate grade by 2%–4%.

Low dust pollution: Since wet separation is carried out in water, there is no dust pollution, which meets environmental protection requirements.

This is the core part of the diaphragm, which consists of multiple arranged permanent magnets. The magnets are made of high-quality ferrite materials or composited with rare earth magnet steel, generating a strong magnetic field to attract magnetic minerals.

The drum is usually made of 2-3 mm stainless steel or other wear-resistant materials and is used to carry and transport materials within the separator.

Magnetic and non-magnetic materials are separated here based on their response to the magnetic field.

This includes the motor, gearbox and pulley. The motor provides the power, which is transferred through the gearbox and pulley to rotate the drum at the correct speed.

Designed to remove magnetic material attracted to the drum, this may include scrapers, brushes or a water wash system.

| Model | Size | Average Value | Working Area | Midfielder Strong Magnetic Field | Capacity | Motor Power (kw) | Revolution | |

|---|---|---|---|---|---|---|---|---|

| t/h | m³/h | |||||||

| CTB-44 | 400×400 | 130 | 180 | 250-400 | 1-2 | 4-5 | 1.1 | 45 |

| CTB-46 | 400×600 | 130 | 180 | 250-400 | 2-3 | 5-10 | 1.1 | 45 |

| CTB-63 | 400×300 | 140 | 180 | 250-400 | 3-5 | 8-15 | 1.1 | 40 |

| CTB-66 | 400×600 | 140 | 180 | 250-400 | 5-10 | 10-30 | 1.1 | 40 |

| CTS-69 | 600×900 | 180 | 180 | 250-400 | 8-15 | 20-50 | 1.1 | 40 |

| CTB-69 | 600×900 | 180 | 180 | 250-400 | 8-15 | 20-50 | 1.1 | 40 |

| CTS-612 | 600×1200 | 140 | 180 | 250-400 | 10-20 | 25-50 | 2.2 | 40 |

| CTB-612 | 600×1200 | 140 | 180 | 250-400 | 10-20 | 25-50 | 2.2 | 40 |

| CTS-618 | 600×1800 | 140 | 180 | 250-400 | 15-30 | 40-80 | 2.2 | 40 |

| CTB-618 | 600×1800 | 140 | 180 | 250-400 | 15-30 | 40-80 | 2.2 | 40 |

| CTS-712 | 750×1200 | 160 | 200 | 300-500 | 15-30 | 40-80 | 3 | 35 |

| CTB-712 | 750×1200 | 160 | 200 | 300-500 | 15-30 | 40-80 | 3 | 35 |

| CTS-718 | 750×1800 | 160 | 200 | 300-500 | 20-45 | 60-100 | 3 | 35 |

| CTB-718 | 750×1800 | 160 | 200 | 300-500 | 20-45 | 60-100 | 3 | 35 |

| CTS-918 | 900×1800 | 170 | 200 | 300-500 | 25-55 | 70-120 | 4 | 28 |

| CTB-918 | 900×1800 | 10 | 200 | 300-500 | 25-55 | 70-120 | 4 | 28 |

| CTS-924 | 900×2400 | 170 | 200 | 300-500 | 35-70 | 80-130 | 4 | 28 |

| CTB-924 | 900×2400 | 170 | 200 | 300-500 | 35-70 | 80-130 | 4 | 28 |

| CTS-1018 | 1050×1800 | 180 | 220 | 300-700 | 40-75 | 110-160 | 5.5 | 22 |

| CTB-1018 | 1050×1800 | 180 | 220 | 300-700 | 40-75 | 110-160 | 5.5 | 22 |

| CTS-1021 | 1050×2100 | 180 | 220 | 300-700 | 50-100 | 140-200 | 5.5 | 22 |

| CTB-1021 | 1050×2100 | 180 | 220 | 300-700 | 50-100 | 140-200 | 5.5 | 22 |

| CTS-1024 | 1050×2400 | 180 | 220 | 300-700 | 80-120 | 170-280 | 5.5 | 22 |

| CTB-1024 | 1050×2400 | 180 | 220 | 300-700 | 80-120 | 170-280 | 5.5 | 22 |

| CTS-1030 | 1050×3000 | 180 | 220 | 300-700 | 70-150 | 200-320 | 7.5 | 22 |

| CTB-1030 | 1050×3000 | 180 | 220 | 300-700 | 70-150 | 200-320 | 7.5 | 22 |

| CTS-1218 | 1200×1800 | 180 | 220 | 300-700 | 60-110 | 160-230 | 5.5 | 19 |

| CTB-1218 | 1200×1800 | 180 | 220 | 300-700 | 60-110 | 160-230 | 5.5 | 19 |

| CTS-1224 | 1200×2400 | 180 | 220 | 300-700 | 70-130 | 60-300 | 7.5 | 19 |

| CTB-1224 | 1200×2400 | 180 | 220 | 300-700 | 70-130 | 60-300 | 7.5 | 19 |

| CTS-1230 | 1200×3000 | 180 | 220 | 300-700 | 80-160 | 250-400 | 7.5 | 19 |

| CTB | ||||||||

Directly contact us with your needs and get a solution in seconds!

E-mail: sales-zjks@zoomjo.cn

Tel: +86-371-87087999

Mobile: +86-15670952888

WhatsApp: +86-13938216895

TikTok

Copyright © Henan ZOOMJO MINING Machinery Co., Ltd. All Rights Reserved.