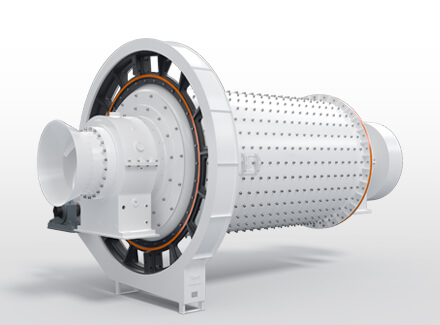

High pressure micro powder mill

Applicable materials: kaolin, limestone, calcite, marble, barite, gypsum, iron oxide, iron oxide green, aluminum hydroxide, pigment, clay, coal, activated carbon, feldspar,talc, carbon black,etc.

Applicable materials: kaolin, limestone, calcite, marble, barite, gypsum, iron oxide, iron oxide green, aluminum hydroxide, pigment, clay, coal, activated carbon, feldspar,talc, carbon black,etc.

In the main unit of the high-pressure micro-powder mill, a high-pressure spring with a pressure of 1000-1500 kg is fastened to the roller hanger. After starting to work, the roller rotates around the main shaft and rolls close to the grinding ring under the action of the high-pressure spring and centrifugal force. Its rolling pressure is 1.2 times higher than that of the Raymond mill under the same power conditions, so the output is greatly improved. This industrial ultra-fine high-pressure micro-powder mill solves the difficulty of ultra-fine powder classification. It is mainly used for ultra-fine powder processing of more than 500 kinds of materials such as feldspar, talc, barite, marble, limestone, carbon black, clay, etc. The fineness is 500 mesh (25 microns)-2500 mesh (5 microns), and the finest powder is 3500 mesh (3.55 microns).

kaolin, limestone, calcite, marble, barite, gypsum, iron oxide, iron oxide green, aluminum hydroxide, pigment, clay, coal, activated carbon, feldspar,talc, carbon black,etc.

Under the same output and fineness, the price of high-pressure micro-powder mill is only one-eighth of that of airflow mill.

Under the same output and fineness, the energy consumption of ultra-fine high-pressure micro-powder mill system is only one-third of that of airflow mill.

The rolling force of the grinding roller on the material is increased by 800-1200Kg under the action of high-pressure spring.

The feed particle size of high-pressure micro-powder mill is large, and the average particle size of the discharge can reach 6.5um ultra-fine powder.

| Model | Micro powder 93 | Micro powder 90 | Micro powder 86 | Micro powder 75 | Grinding 65 |

|---|---|---|---|---|---|

| Feed size (mm) | ≤25 | ≤25 | ≤20 | ≤20 | ≤15 |

| Finished product size (mm) | 0.125-0.010 | 0.125-0.010 | 0.125-0.010 | 0.125-0.010 | 0.125-0.010 |

| Capacity(t/h)(based on different raw material fineness) | 1-21 | 1-20 | 0.5-12 | 0.3-8 | 0.2-8 |

| Center shaft speed (rpm) | 160 | 160 | 160 | 160 | 180 |

| Grinding ring inner diameter (mm) | 1006 | 973 | 907.5 | 865 | 725 |

| Grinding roller diameter (mm) | 300 | 300 | 270 | 260 | 210 |

| Grinding roller and grinding ring height (mm) | 160 | 160 | 150 | 150 | 150 |

| Main motor (KW) | y225m-8-30 | y225m-8-30 | y225m-8-22 | y225m-8-18.5 | y225m-8-15 |

| Fan motor (KW) | y160E-2-22 | y180m-4-22 | y160L-4-15 | y160L-4-15 | y160L-4-11 |

| Analyzer motor (KW) | y112m-4-3 | yc20-4A-3 | yc120-4A-3 | yc120-4A-3 | yc120-4A-3 |

Directly contact us with your needs and get a solution in seconds!

E-mail: sales-zjks@zoomjo.cn

Tel: +86-371-87087999

Mobile: +86-15670952888

WhatsApp: +86-13938216895

TikTok

Copyright © Henan ZOOMJO MINING Machinery Co., Ltd. All Rights Reserved.