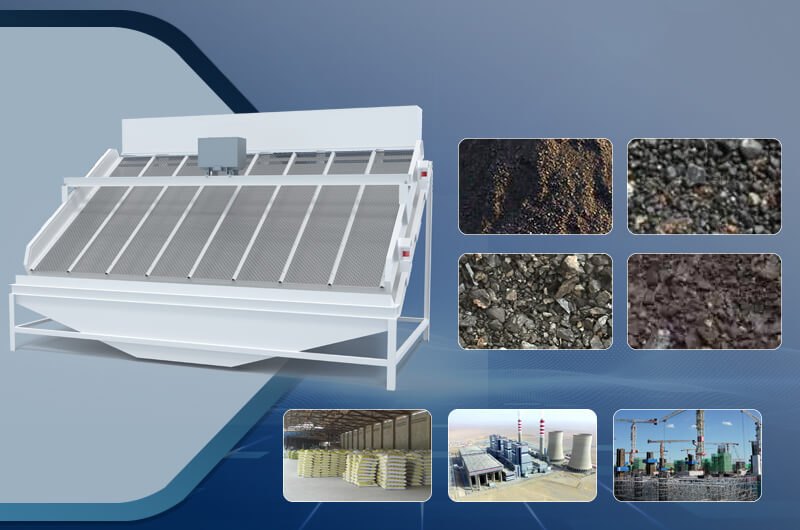

High frequency screening

Applicable materials: Screening or grading operations in ore dressing plants such as iron ore, tin, tungsten, tantalum, and niobium sand.

Applicable materials: Screening or grading operations in ore dressing plants such as iron ore, tin, tungsten, tantalum, and niobium sand.

The high-frequency screen is composed of vibrator, slurry distributor, screen frame, chassis, suspension spring, screen mesh and other components. The mineral high-frequency screen has the following advantages: high efficiency, low amplitude, and high-frequency screening.

The principle of the high-frequency screen is different from the general one. It uses high-frequency technology.

Screening or grading operations in ore dressing plants such as iron ore, tin, tungsten, tantalum, and niobium sand.

The laminated mesh increases the single-layer aperture, which not only increases the service life of the screen, but also prevents jamming and wear.

The rubber spring of the high-frequency screen supports the screen frame, which reduces noise and setting vibration.

Its low amplitude makes it easy to sort fine and heavy materials.

High production capacity and low energy consumption.

| Model | Capacity(t/h) | Power(kw) |

|---|---|---|

| GPS-4 | 15-25 | 0.72 |

| GPS-5 | 20-30 | 1.1 |

| GPS-6 | 24-36 | 1.5 |

| GPS-8 | 32-48 | 2.2 |

Directly contact us with your needs and get a solution in seconds!

E-mail: sales-zjks@zoomjo.cn

Tel: +86-371-87087999

Mobile: +86-15670952888

WhatsApp: +86-13938216895

TikTok

Copyright © Henan ZOOMJO MINING Machinery Co., Ltd. All Rights Reserved.