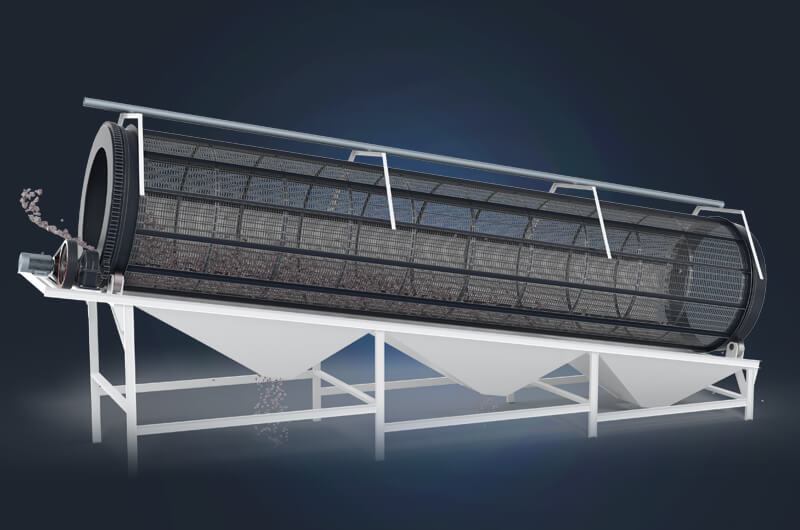

Drum screen

Product features: Used for grading powdery materials, good screening effect, 60-200 mesh screen

Product features: Used for grading powdery materials, good screening effect, 60-200 mesh screen

Drum screen, also known as rotary drum screen or drum screen, is a self-cleaning screening machine that separates materials by size.

Compared with vibrating screen, drum screen can avoid clogging and achieve high output even with dust and sticky materials.

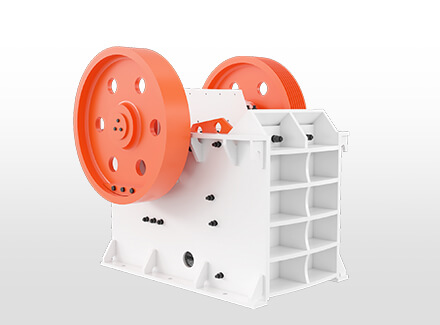

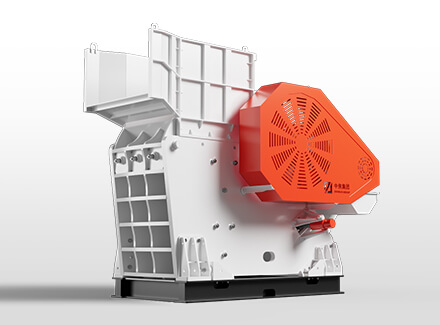

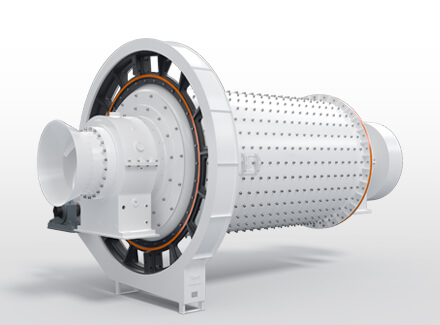

Drum screen is usually used in conjunction with mineral processing equipment, such as crusher and ball mill.

Stone quarries (such as granite): used for grading large and small stones and separating soil and stone powder

Gravel fields (such as quartz sand): used for sand and gravel separation

Coal industry (such as coal gangue): used for separating lumps of coal and coal powder and washing coal

Chemical and mineral processing industries: used for grading large and small pieces and separating powdered materials

1. Small installation angle, not easy to clog.

2. Small space occupied, convenient for process layout, large output.

3. Low noise, less dust pollution.

4. Smooth operation and high screening efficiency.

The drum screen is larger and is a cylinder with holes mounted at an angle on the frame. The inclination angle is between 5-30°, closer to 30° for light and fine material and less than 20° for heavier material, and can be reduced to 5-10°in special cases.

The main wearing parts of the drum screen include the drum, screen, drive system, bearings and discharge port.

The drum is the main component of the drum screen and is made of steel. It is a cylindrical structure that rotates around its axis and tilts at a certain angle to allow the material to tumble inside.

The drum screen must be equipped with a steel ring to prevent the drum screen from deforming.

The screen is installed inside the drum screen and is mainly made of stainless steel. The raw material is non-sticky, easy to clean, and has no sanitary dead corners.

The size of the opening in the screen can be customized to suit specific applications and required output sizes.

The screen of the drum screen can be divided into woven type and one or two layers of punching.

The drive system is used to rotate the drum, which is powered by a motor and a reducer, which drive the drum to rotate through bearings.

Due to the rotation of the drum, the material passes through the screen from high to low and is successfully screened out.

The tension of the belt loosens the screws between the reducer and the motor. You should frequently check the tightness of the bolts and belts to avoid belt slippage.

The bearings bear all the load of the drum screen machine.

Good lubrication has a great relationship with the life of the bearings, which directly affects the service life and operation rate of the machine.

The discharge chute is located at the end of the drum and is used to discharge the screened material into a conveyor or container.

The discharge port is often blocked, so its angle should be as perpendicular to the ground as possible. Its diameter should be large to facilitate the discharge of materials.

| Model | Specification (mm) | Roller length(mm) | Speed (r/min) | Capacity (t/h) | Motor | Power(kw) |

|---|---|---|---|---|---|---|

| GS1410 | Φ1400/Φ1000 | 1500 | 20 | 10-20 | Y100L2-4 | 3 |

| GS1612 | Φ1600/Φ1200 | 1800 | 18 | 20-30 | Y112M-4 | 4 |

| GS2014 | Φ2000/Φ1400 | 2000 | 14 | 30-40 | Y132S-4 | 5.5 |

Directly contact us with your needs and get a solution in seconds!

E-mail: sales-zjks@zoomjo.cn

Tel: +86-371-87087999

Mobile: +86-15670952888

WhatsApp: +86-13938216895

TikTok

Copyright © Henan ZOOMJO MINING Machinery Co., Ltd. All Rights Reserved.