Types of industrial coolers: single cylinder cooler, double cylinder cooler, grate cooler, clinker cooler and so on.

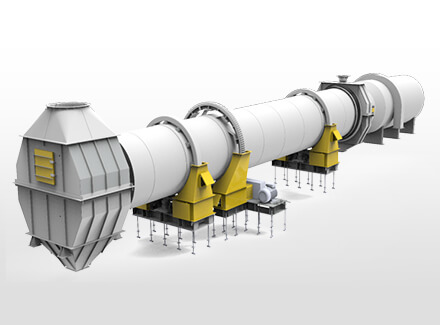

Single cylinder cooler is one of the important equipments in the rotary kiln system, the function of this equipment is to cool the clinker (1000-1300℃) coming out from the rotary kiln to below 200℃, and at the same time to improve the clinker quality and grindability.

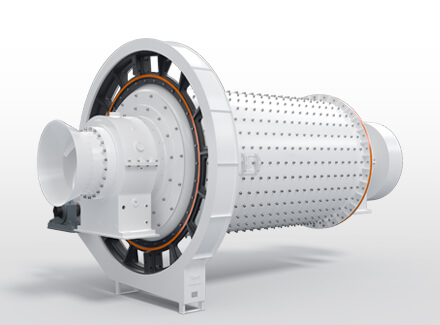

Clinker cooler is an important supporting equipment of cement rotary kiln. Without the corresponding high efficiency cooler, it is impossible to have a high efficiency rotary kiln.

Grate cooler is a cooling equipment that uses certain pressure air to polycool the moving clinker on the castor bed in a mutually perpendicular direction of movement.

Lime Cooler: Vertical cooler is one of the hosts of active lime. After calcination of rotary kiln generated after the active lime flows into the refractory vertical cooler in turn, the cooler cross-section for the square, in which there is a uniform distribution of the center of the cold cap and the chamber cold cap, the cap has a pipeline connected to the external fan, in the bottom of the cooler is equipped with a discharge port, each under the discharge port of a motor vibration unloader. Material in the cooler is piled up to cover the cap and form a certain material layer thickness, cooling wind is blown in by the external fan, through the wind chamber into the cap.

The cooling air is blown in by the external fan and enters into the air cap through the air chamber. After coming out from the air cap and contacting with the high temperature material, the heat exchange is completed, and the material cooled by the air is gradually excluded from the cooler under the action of the motor vibrating unloader, and the air heated by the material enters into the rotary kiln directly by the kiln head hood, and participates in the combustion as the secondary air.

Compact structure, reliable operation, low failure rate

Easy operation, low maintenance cost

Especially suitable for small and medium-sized cement plants

High heat recovery efficiency, remarkable energy saving effect

| Specifications (m) (diameter x length) | Capacity (t/h) | Installation slope (%) | MainGear reducer | Main motor(kw) | Total weight (t) |

| Φ1.5×15 | 2-3 | 3-5 | ZQ500 | 15 | 28 |

| Φ1.5×20 | 3-4 | 3-5 | ZQ500 | 15 | 35 |

| Φ1.8×18 | 4-6 | 3-5 | ZQ500 | 18.5 | 47 |

| Φ2.0×22 | 7-8.5 | 3-5 | ZQ500 | 22 | 61 |

| Φ2.2×18 | 7-8.5 | 3-5 | ZQ500 | 22 | 64 |

| Φ2.2×22 | 8-10 | 3-5 | ZQ650 | 30 | 73 |

| Φ2.4×24 | 12-15 | 3-5 | ZS125 | 45 | 98 |

| Φ2.5×25 | 15-20 | 3-5 | ZS125 | 55 | 110 |

| Φ2.8×28 | 16-22 | 3-5 | ZL100 | 55 | 130 |

| Φ3.0×30 | 20-25 | 3-5 | ZL115 | 75 | 169 |

| Φ3.2×36 | 28-32 | 3-5 | ZL115 | 90 | 200 |

| Φ3.3×40 | 32-36 | 3-5 | ZL130 | 132 | 237 |

| Φ3.6×36 | 35-38 | 3-5 | ZSY450-28 | 185 | 318 |

| Φ4.0×36 | 50-60 | 3-5 | ZSY450-25 | 220 | 348 |

| Φ4.0×45 | 60-70 | 3-5 | ZSY450-25 | 250 | 414 |

| Φ4.5×50 | 70-75 | 3-5 | ZSY500-25 | 315 | 576 |

Directly contact us with your needs and get a solution in seconds!

E-mail: sales-zjks@zoomjo.cn

Tel: +86-371-87087999

Mobile: +86-15670952888

WhatsApp: +86-13938216895

TikTok

Copyright © Henan ZOOMJO MINING Machinery Co., Ltd. All Rights Reserved.