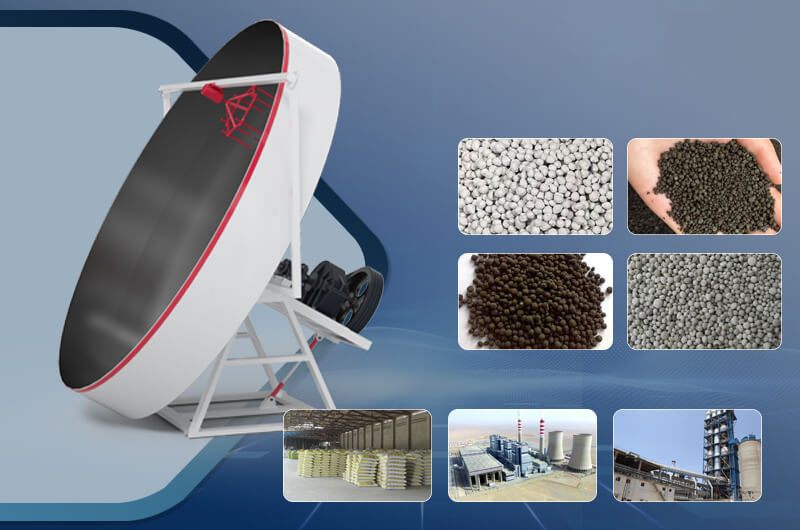

Disc granulator

Applicable materials: coal powder, cement, clinker, limestone, shale, coal gangue, clay and other powdered, granular or small block materials, etc.

Applicable materials: coal powder, cement, clinker, limestone, shale, coal gangue, clay and other powdered, granular or small block materials, etc.

The disc granulator is a modification of ZOOMJO GROUP based on the advanced technology of similar equipment at home and abroad. The disc granulator is lined with high-strength fiberglass, which has the advantages of uniform granulation, high granulation rate, stable operation, durable equipment and long service life. It is an ideal granulation equipment.

coal powder, cement, clinker, limestone, shale, coal gangue, clay and other powdered, granular or small block materials, etc.

The granulator has a novel structure, light weight, low height and flexible process layout.

The disc granulator adopts an overall arc structure, and the granulation rate can reach more than 95%.

The inclination angle of the disc can be adjusted (35–55°). Angle gaskets are used for flexible and convenient adjustment.

90% of the particle diameter is 3-6 mm. The granulation effect is good and there will be no large mud balls.。

The transmission gear is treated with high-frequency quenching and has a long service life.

It can be automatically graded according to the particle size, and the discharged ball products are qualified.

New dredging design. The scraper device consists of a non-powered combined scraper and a corner scraper, which can clean the bottom and edge and save labor.

It consists of a granulating disc, a scraper, an angle adjuster, a motor, a reducer, a frame, a base, etc.

The disc adopts an arc structure and is horizontally mounted on a rotating shaft. It is the platform for the granulation process, including a main shaft, two sets of roller bearings and two shaft blocks. The bottom of the disc is reinforced with multiple heat dissipation steel plates, which has high strength and good rigidity.

The scraper system consists of a scraper and a scraper holder, and the scraper is installed on the top of the granulating disc. When the disc rotates, the scraper prevents excessive accumulation of materials, promotes uniform mixing, and promotes granule formation.

The angle tilt adjuster allows the operator to modify the position angle of the puck relative to the horizontal plane. By adjusting the angle 35-55°, the residence time of the material on the disc can be controlled, affecting the particle growth process.

The reducer and motor work together to ensure that the disc rotates at the optimal speed for granulation. The reducer and motor are driven by a flexible belt, which ensures smooth start-up of the equipment, small impact force and longer service life.

| Model | Disc Diameter (mm) | Disc Height (mm) | Inclination Angle (°) | Speed (r/min) | Main Motor Power (kw) | Scraper Motor Power (kw) | Weight (t) |

|---|---|---|---|---|---|---|---|

| PQ10 | 1000 | 250 | 35-55 | 2.5-25 | 3 | 1.1×1 | 0.6 |

| PQ12 | 1200 | 250 | 35-55 | 2.5-25 | 4 | 1.1×1 | 0.8 |

| PQ16 | 1600 | 300 | 35-55 | 2-19 | 7.5 | 1.5×1 | 1.4 |

| PQ20 | 2000 | 320 | 35-55 | 1.5-15 | 7.5 | 2.2×1 | 2.2 |

| PQ22 | 2200 | 350 | 35-55 | 1.4-14 | 15 | 2.2×1 | 3.8 |

| PQ25 | 2500 | 350 | 45-55 | 1.2-12 | 15 | 2.2×1 | 5 |

| PQ28 | 2800 | 400 | 45-55 | 1.2-12 | 18.5 | 2.2×1 | 5.8 |

| PQ32 | 3200 | 400 | 45-55 | 1.2-12 | 22 | 3×1 | 8.5 |

| PQ36 | 3600 | 550 | 45-55 | 1-10 | 30 | 3×2 | 9.8 |

| PQ42 | 4200 | 550 | 45-55 | 1-10 | 37 | 4×2 | 12.5 |

| PQ45 | 4500 | 550 | 45-55 | 1-9 | 45 | 4×2 | 13.5 |

| PQ50 | 5000 | 650 | 43-53 | 6-9 | 55 | 5.5×2 | 18 |

| PQ55 | 5500 | 650 | 43-53 | 5.7-8.5 | 75 | 5.5×2 | 30.2 |

| PQ60 | 6000 | 650 | 43-53 | 5.7-8.5 | 90 | 5.5×2 | 32.8 |

| PQ70 | 7000 | 650 | 43-53 | 5.1-7.9 | 132 | 5.5×3 | 45.9 |

| PQ75 | 7500 | 650 | 43-53 | 5.1-7.9 | 160 | 5.5×3 | 50 |

Directly contact us with your needs and get a solution in seconds!

E-mail: sales-zjks@zoomjo.cn

Tel: +86-371-87087999

Mobile: +86-15670952888

WhatsApp: +86-13938216895

TikTok

Copyright © Henan ZOOMJO MINING Machinery Co., Ltd. All Rights Reserved.