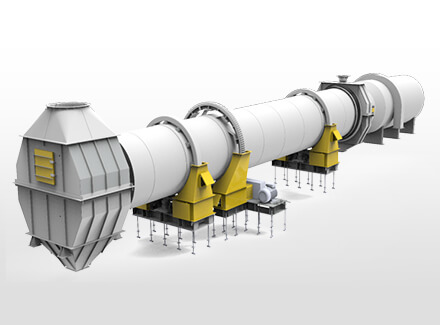

Air-Swept Coal Mill

Applicable materials: raw coal, etc.

Applicable materials: raw coal, etc.

Air-swept coal mill, also called coal mill, is a device used to grind and dry coal of various hardness. It is mainly composed of feeding device, main bearing, rotating part, transmission device, feeding and discharging device, high-voltage starting device and lubrication system. It is widely used in cement building materials, thermal power generation, metallurgical industry, chemical industry, etc. Air-swept coal mill has reasonable structure and high grinding efficiency. It is an ideal equipment for coal powder preparation.

How to choose a coal mill

The type of coal mill is selected based on the type of coal (bituminous coal, anthracite, lignite) and its hardness, grindability index, temperature and type of desiccant, and the capacity is selected based on the expected grinding volume.

According to the different speeds of coal mills, they can be roughly divided into the following three types:

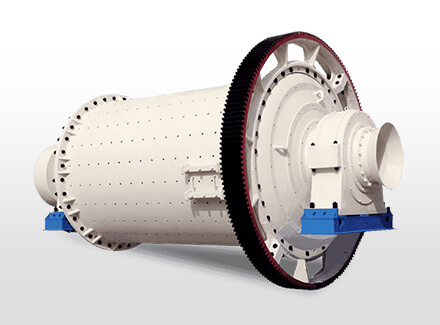

Low-speed coal mill: Its speed range is 15–25 r/min. Low-speed coal mills include cylindrical steel ball mills, steel ball mills with two symmetrical grinding circuits, etc.

Medium-speed coal mill: Its speed range is 50–300 r/min.

High-speed coal mill: Its speed range is 500-1,500 r/min.

Mainly composed of feeding device, main bearing, rotating part, transmission device, unloading device, high-pressure starting device, lubrication system, etc.

Shutter structure: supports angled feeding, ensures uniform mixing of air and materials, and improves feeding smoothness.

Sealing design: A sealing device is set at the contact point between the feeding device and the rotating part to effectively prevent cold air from infiltrating.

Adjustable installation: A gasket can be filled between the feeding pipe and the air inlet pipe, and the bracket height can be adjusted to facilitate precise alignment.

Core grinding structure: It consists of hollow shaft, cylindrical cylinder, lifting plate, partition plate, wear-resistant lining plate and steel ball grinding media to realize efficient drying and grinding of raw coal.

Edge transmission system: the main motor drives the mill at low speed through reducer + gear set to ensure stable power output.

Convenient maintenance design: pinion gear and gear shaft are connected by conical lock, which is convenient for installation and disassembly, avoiding problems such as gear eccentricity and slipping, and prolonging service life.

Wear-resistant elbow + liner: reduce the wear and tear of material scouring, prolong the life of the equipment.

Spiral return system: the coarse powder that does not meet the standard is automatically sent back to the grinding silo through the spiral cylinder, avoiding the accumulation of slag, reducing manual cleaning, and guaranteeing the safe production and environmental protection operation.

Modification measures: Replacement of high-efficiency thermal insulation materials and installation of additional air locking devices at the head of the coal mill to reduce cold air infiltration.

Effect: The hot air temperature is raised from 190°C to 220°C~240°C, which significantly improves the drying efficiency.

Adjustment of bin ratio: shortening the drying bin from 3m to 2.1m, extending the grinding bin by 0.9m, and optimizing the length ratio to 1:2.81 (originally 1:1.67).

Matching upgrade: increase the steel ball loading capacity and match a higher power motor.

Advantages: improve the processing capacity of inferior coal and grind more fully.

Screening design: the liner plate at the discharge end is equipped with rectangular screen holes, combined with the inner and outer spiral pipe to realize dynamic sorting of steel balls.

Operation mechanism: unqualified steel balls are discharged automatically and qualified steel balls are recycled without downtime for cleaning.

Product Specification | Φ1.7×2.5 | Φ2.2×4.4 | Φ2.4×4.75 | Φ2.4×4.5+2 | Φ2.6×5.25+2.25 | Φ2.8×5+3 | Φ3.0×6.5+2.5 | Φ3.2×6.75+2 | Φ3.4×6+3 | Φ3.8×7+2.5 | |

Speed(r/min) | 24.5 | 22.4 | 20.4 | 20.4 | 19.7 | 18.3 | 18.3 | 16.9 | 17.5 | 16.4 | |

Capacity(t/h | 3-5 | 8-9 | 12-14 | 11-12 | 13-14 | 16-17 | 19-20 | 25-30 | 28-30 | 38-40 | |

Feeding Size(mm | <25 | <25 | <25 | <25 | <25 | <25 | <25 | <25 | <25 | <25 | |

Grinding Media Loading(t | 7.5 | 20 | 22 | 22.5 | 28 | 32 | 43 | 50 | 55 | 80 | |

Main Gear Reduce | ZD40 | ZD60 | ZD60 | ZD60 | ZD70 MBY450 | ZD70 MBY500 | ZD80 MBY560 | JDX560 | JDX710 | MBY800 | |

Main motor(kw) | 95 | 250 | 280 | 315 | 400 | 500 | 630 | 710 | 800 | 1250 | |

Total weight (t) | 29 | 46 | 54 | 76 | 98 | 107 | 124 | 148 | 162 | 215 | |

Directly contact us with your needs and get a solution in seconds!

E-mail: sales-zjks@zoomjo.cn

Tel: +86-371-87087999

Mobile: +86-15670952888

WhatsApp: +86-13938216895

TikTok

Copyright © Henan ZOOMJO MINING Machinery Co., Ltd. All Rights Reserved.