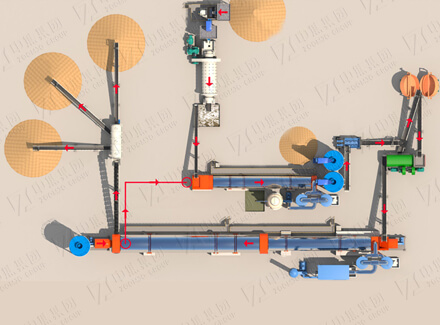

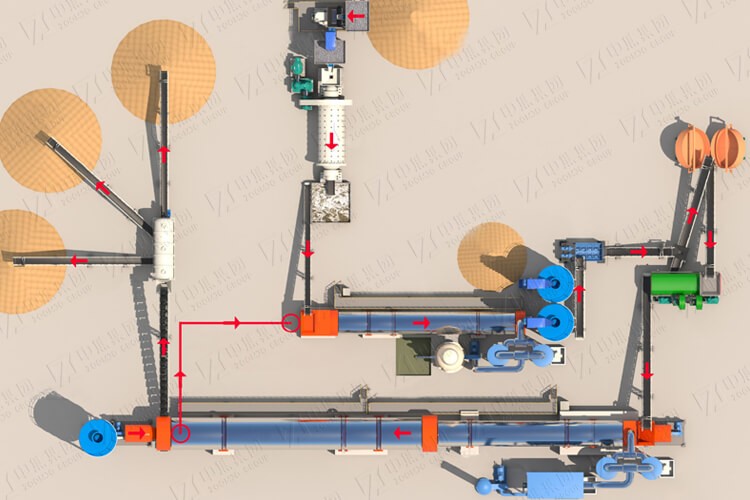

1. System Overview

LECA (Lightweight Expanded Clay Aggregate) is a porous lightweight building material made by high-temperature sintering process, which is widely used in green buildings, hydroponic gardening, water treatment and other fields. This production line has a designed capacity of 1.9-76 t/h, suitable for raw materials such as clay, shale, industrial waste, etc., and produces aggregates with a density of 300-900 kg/m³ and a particle size of 0.1-25 mm to meet the needs of different scenarios. The finished product has the characteristics of high strength, heat insulation and sound insulation, environmental protection and non-toxicity, and complies with the EN 13055-1 international standard.

2. Core Process System

Raw material pretreatment module

Coarse crushing: jaw crusher (feed ≤ 1200mm → discharge 10-350mm)

Fine grinding: ball mill (particle size ≤ 0.075mm, accounting for ≥ 90%)

Mixing and tempering: double-shaft mixer (clay: shale = 1:1, moisture content 15-20%)

Forming and drying modules

| Equipment | Function | Key parameters |

|---|---|---|

| Disk granulator | Prepare spherical particles (particle size 5-25mm) | Ball formation rate ≥93%, production capacity 4-24t/h |

| Drum dryer | Pre-dry to moisture content ≤8% | Hot air temperature 850℃, processing capacity 76t/h |

High temperature sintering module

Rotary kiln system:

Sintering temperature: 1100-1250℃ (precise temperature control ±10℃)

Residence time: 45-60 minutes (expansion rate control ±5%)

Fuel: natural gas/biomass pellets (heat consumption ≤850kcal/kg)

Cooling system:

High-efficiency cooler (discharge temperature ≤ 200 ℃, recycled heat utilization rate ≥ 30%)

Finished product processing module

Grading and screening: multi-stage trommel screen (grading accuracy ±1mm)

Intelligent packaging: ton bag/25kg bag dual mode packaging line (speed 40 bags/minute)

3.Equipment configuration and technical parameters

| Equipment module | Technical indicators |

|---|---|

| Jaw crusher | Processing capacity 435t/h,power 160kW |

| Ball mill | Cylinder speed 19r/min,installed power 1250kW |

| Rotary kiln | Production capacity 10000t/d, Slope 3.5% |

| Trommel screen | Screening efficiency ≥95%, processing capacity 280t/h |

| Dust removal system | Emission concentration ≤10mg/m³, filtration area 1280㎡ |

4.Performance Indicators and Grading Applications of LECA

| Particle size (mm) | Density (kg/m³) | Compressive strength (MPa) | Typical applications |

|---|---|---|---|

| 0-4 | ≤710 | 3.0-7.0 | Lightweight concrete, water filtration |

| 4-10 | ≤480 | 2.5-5.0 | Green roof, noise barrier |

| 10-20 | ≤380 | 1.5-3.0 | Horticultural substrate, road filling |

| 0-25 | ≤430 | 2.0-4.0 | Building decoration, aquaculture |

5. Technical Advantages

Highly efficient energy saving

Waste heat recovery system: reduce energy consumption by 25% (compared with traditional process)

Intelligent temperature control technology: rotary kiln thermal efficiency is increased to 85%.

Environmental innovation

Zero wastewater discharge: Dry condensate water recycling

Low-carbon process: Support biomass fuel substitution, CO₂ emission reduction by 30%

Intelligent control

DCS central control system: real-time monitoring of 200+ process parameters

AI quality prediction: prejudge the expansion rate through the kiln temperature curve, accuracy ≥95%.

Raw material adaptability

Can handle gangue, tailings and other industrial solid wastes (substitution rate ≤50%)

Clay moisture content tolerance up to 25% (pre-drying system adjustment)

6.Typical Customer Cases

Case 1: European Green Building LECA Project

Production capacity: 50t/h

Raw material: shale + construction waste soil (1:1 mix)

Achievements:

Aggregate density 420kg/m³, thermal conductivity 0.12W/(m·K)

Applied to passive buildings, energy saving rate increased by 40%

Case 2: Southeast Asia hydroponic gardening substrate line

Configuration:

Disk granulator (particle size 4-8mm)

Low-temperature sintering process (1050℃)

Indicator:

pH neutral (6.8-7.2), porosity ≥65

Annual supply of horticultural substrate 200,000 tons

7. Core Services

Full-cycle support

EPC general contracting service: including process design-equipment installation-worker training

Intelligent operation and maintenance system: equipment health monitoring + remote fault diagnosis

English

English

中文

中文