1. Process Overview

Manganese ore is a weakly magnetic mineral. The strong magnetic-medium magnetic combined process is the core technology. Through multi-stage magnetic separation and classification, efficient enrichment of manganese ore can be achieved. The customized solution of Zoomjo can increase the manganese grade by 4%-10%, and the concentrate recovery rate can reach 85%-95%. It is suitable for low-grade manganese ore (15%-25%) and complex embedded ore bodies.

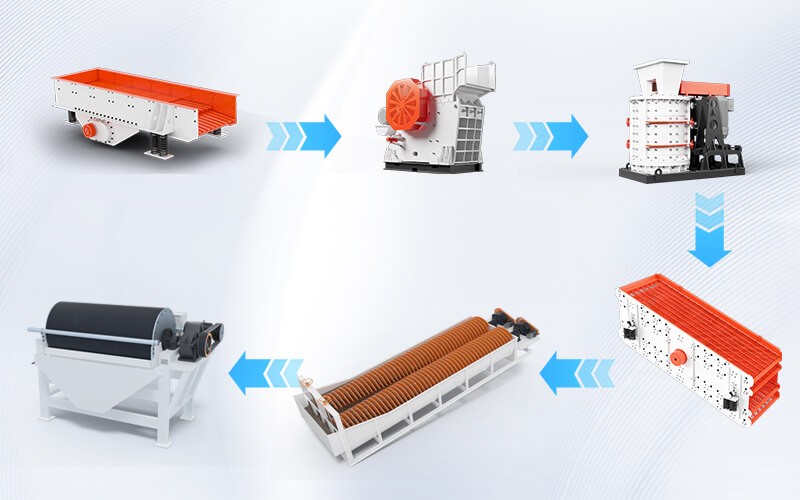

2. Core process flow

1. Crushing pretreatment

Coarse crushing: jaw crusher processes raw ore to 100-200mm, with a processing capacity of 5000t/d; Fine crushing: CNC sand machine accurately controls particles to 0-30mm, reducing over-crushing and reducing energy consumption by 20%.

2. Strong magnetic roughing (primary enrichment)

Equipment: high gradient magnetic separator (magnetic field strength 1.2-1.5T);

Technical highlights:

Quickly discard 60%-70% of gangue, and increase the manganese grade of coarse concentrate to 25%-30%;

The tailings are directly discharged into the concentrator to reduce ineffective circulation.

3. Grading optimization (granularity control)

Spiral classifier:

The bottom flow (coarse particle size) enters the medium magnetic separation, and the overflow (fine particle size) is concentrated and reused;

Classification efficiency>85%, accurately separating +0.1mm and -0.1mm particles.

4. Medium magnetic separation (deep purification)

Equipment: Permanent magnetic cylinder medium magnetic machine (magnetic field strength 0.6-0.8T);

Technical highlights:

Secondary separation removes residual quartz and clay, and the manganese grade of the concentrate reaches 35%-40%;

The manganese loss rate of tailings is less than 5%, and the resource utilization rate is maximized.

5. Concentration and dehydration (closed loop)

Concentration system:

High-efficiency thickener sedimentation, bottom flow concentration>60%, overflow return water rate≥90%;

Dry tailings discharge:

Combined process of dewatering screen + filter press, tailings moisture content < 15%, can be directly stored or made into building materials.

3. Technical advantages and benefits

Taste Leap:

The manganese grade of the raw ore is 18% → the grade of the concentrate is 38%-45%, and the purification rate exceeds 100%;

Compared with the traditional single magnetic separation, the recovery rate is increased by 10%-15%.

Energy saving and consumption reduction:

CNC sand machine + closed-circuit grading system, energy consumption per ton of ore is reduced by 25%;

Power consumption of strong magnetic machine is less than 3kW·h/t, and operating cost is leading in the industry.

Green production:

Tailings dry discharge technology reduces storage capacity pressure, and water recycling saves 30% of water resources;

dust closed collection system, PM2.5 in the working area<15μg>

4. Production Example: A Low-Grade Manganese Mine Project in Guangxi (3000t/d)

Ore characteristics:

Manganese grade 19.5%, fine embedded particle size (-0.074mm accounting for 65%), containing quartz and clay.

Process design:

Strong magnetic roughing: tailing rate 65%, coarse concentrate grade 28.3%;

Medium magnetic concentrating: concentrate grade increased to 42.7%, recovery rate 89.4%.

English

English

中文

中文