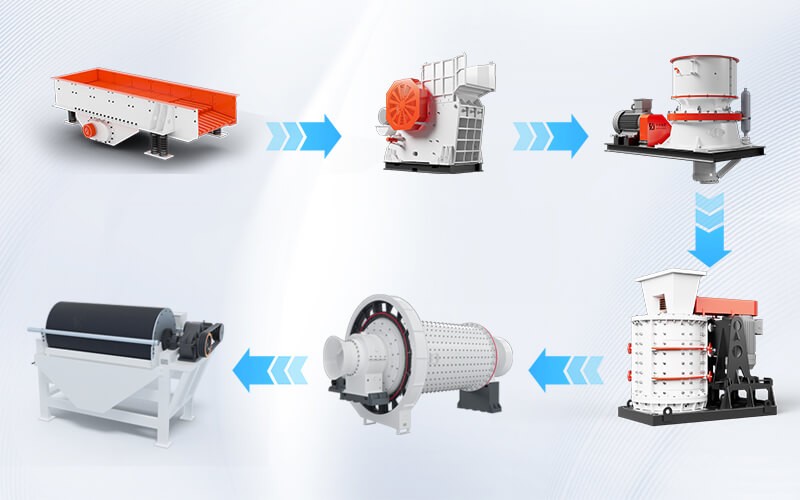

1. Process Overview

Magnetite is a strongly magnetic mineral. The core process of mineral processing is weak magnetic separation. Combined with the characteristics of the ore, it is flexibly matched with gravity separation, flotation, roasting and magnetic separation to achieve efficient separation. According to the difference in magnetic strength, the process is divided into two categories:

Strong magnetic iron ore process: suitable for low-grade magnetite, using stage grinding or multi-stage grinding process, medium coke fine grinding technology can increase the concentrate grade to 67%.

Weak magnetic iron ore process: after being converted into a strongly magnetic mineral through magnetization roasting, it is processed according to conventional magnetic separation method.

2. Applicable ore body characteristics

Strong magnetic ore body: mainly magnetite, with coarse or fine embedded particles, easy to select but energy consumption needs to be optimized.

Weak magnetic ore body: requires magnetization roasting pretreatment, with complex associated minerals (such as quartz, sulfur, titanium).

Composite ore body: contains recyclable elements such as sulfur and titanium, requiring multiple processes for coordinated sorting.

3. Process advantages

Fine grinding technology innovation

Two-stage grinding + fine screening and re-grinding process reduces over-grinding, increases concentrate grade by 2%, and increases processing capacity by 15%.

Zoomjo fine grinding technology enables concentrate grade to exceed 67%, reaching the industry-leading level.

Staged grinding and selection reduces costs and increases efficiency

The "early collection and early disposal" strategy combines staged grinding with multi-stage magnetic separation to reduce energy consumption by 20%-30%.

Composite process collaborative separation

The combined process of magnetic separation, gravity separation and flotation can simultaneously recover associated minerals such as sulfur and titanium, increasing resource utilization by 40%.

Fully closed-circuit system optimization

Six-stage grinding and separation closed-circuit process ensures smooth process and stable recovery rate of over 90%.

4. Typical Cases

Case 1: A low-grade magnetite technical transformation project in Inner Mongolia

Ore characteristics: ore grade 12%-16%, fine embedded particle size, strong magnetism.

Original process pain points: high cost of three-stage grinding, concentrate grade 65.58%.

ZOOMJO GROUP solution: stage grinding + stage separation, optimized closed-circuit system.

Results:

The concentrate grade increased to 67.81%, and the recovery rate was 92.69%;

Energy consumption decreased by 25%, and the annual cost savings exceeded 3 million yuan.

Case 2: Xinjiang 3300t/d Iron Mine EPC Reconstruction Project

Core technology: three-stage grinding, six-stage closed-circuit magnetic separation + double dehydration of concentrate and tailings.

Innovations:

Maximize the use of existing equipment and add a new concentrator to realize tailings water recycling;

The dehydration efficiency of the disc filter is increased by 30%, and the moisture content of the concentrate is ≤8%.

Results: The recovery rate has stabilized at 90.5%, and customer satisfaction is 100%.

Case 3: Anhui 600t/d polymetallic iron ore project

Ore complexity: Contains iron, sulfur and titanium, requiring coordination of multiple processes.

Scheme design:

Stage grinding, six-stage magnetic separation (iron recovery) → gravity separation and tailings discarding → flotation separation of sulfur and titanium.

Environmental protection: dust closed collection, wastewater recycling rate> 85%.

Comprehensive benefits:

Iron concentrate grade 65.2%, sulfur recovery rate 78%, titanium recovery rate 62%;

Tails dry stack, certified as "green mine".

English

English

中文

中文