1. System Overview

The magnetic separation equipment is specially designed for mineral separation. It is suitable for the extraction and purification of magnetic minerals such as magnetite, hematite, ilmenite, etc. (specific magnetic susceptibility ≥3.8×10⁵ m³/kg), and can also remove magnetic impurities in non-magnetic ores. It is suitable for wet/dry separation processes, with a processing capacity of 10-280 t/h, a concentrate recovery rate of ≥90%, and a residual magnetic substance in tailings of ≤5%, meeting the needs of efficient separation and maximum resource utilization in mines.

2. Core Process System

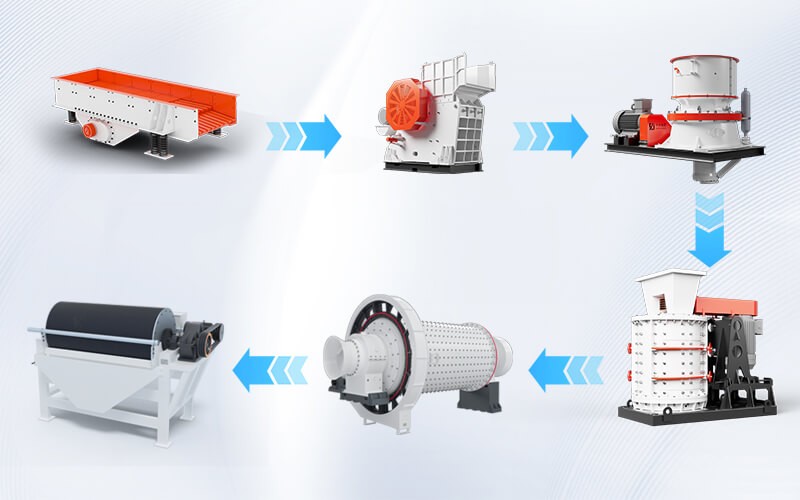

Pretreatment system

Crushing and grading: jaw crusher (coarse crushing to ≤100mm) → cone crusher (medium crushing to ≤30mm) → ball mill (fine grinding to ≤0.075mm, accounting for 90%)

Screening control: high-frequency vibrating screen (grading accuracy ±0.1mm)

Magnetic separation module

| Sorting stage | Equipment type | Magnetic field strength | Applicable minerals |

|---|---|---|---|

| Rough selection | CTG dry magnetic separator | 800-1500 GS | Strongly magnetic minerals (magnetite) |

| Sweep selection | SLon high gradient magnetic separator | 10000-20000 GS | Weakly magnetic minerals (hematite) |

| Fine selection | Wet drum magnetic separator | 400-1200 GS | Fine-grained embedded minerals |

Aftertreatment system

Concentration and dehydration: high-efficiency concentrator (underflow concentration ≥ 65%) → ceramic filter (water content ≤ 10%)

Drying and packaging: rotary dryer (hot air temperature 200-350℃) → fully automatic ton bag packaging machine

3.Technical parameters and configuration solutions

| Indicators | Standard type (wet selection) | High efficiency type (dry selection) | Ultra-fine type (high gradient) |

|---|---|---|---|

| Processing capacity | 50-150 t/h | 30-100 t/h | 10-50 t/h |

| Magnetic field strength | 400-1200 GS | 800-1500 GS | 10000-20000 GS |

| Particle size range | 0.1-3 mm | 1-30 mm | 0.01-0.1 mm |

| Energy consumption | 3-5 kWh/t | 2-4 kWh/t | 8-12 kWh/t |

| Recovery rate | ≥92% | ≥88% | ≥85% |

4. Advantages of magnetic separation process

Sorting efficiency

Strong magnetic minerals: single separation efficiency ≥ 95% (magnetite concentrate grade ≥ 68%)

Weak magnetic minerals: gradient magnetic separation increases recovery rate by 20-30% (hematite TFe ≥ 60%)

Energy saving and environmental protection

Dry sorting: 100% water saving, suitable for arid areas

Closed-loop water system: water resource recycling rate ≥ 85%

Dust control: pulse dust removal system (emission concentration ≤ 10mg/m³)

5. Typical application cases

Case 1: Indian hematite sorting line

Raw materials: hematite ore (TFe 48-53%)

Process: two-stage ball milling → weak magnetic-strong magnetic separation

Results: concentrate TFe 67-68%, recovery rate 95%, production capacity 15t/h

Case 2: Nigerian manganese ore purification project

Challenge: Manganese content 28%, fine embedded particle size (<0.5mm)

Solution: Crushing to 70mm → Jigging pre-selection → Strong magnetic separation (15000 GS)

Result: Manganese content of concentrate 41.23%, recovery rate 93.6%

Case 3: Pakistani coal powder desulfurization

Requirement: Reduce the sulfur content in coal (original sulfur 0.11%)

Technology: Wet high gradient magnetic separation (1.0T) → flotation sweeping separation combined process

Result: Clean coal fixed carbon recovery rate 98.7%, ash content ≤2.86%

6. Equipment Selection Guide

Select by mineral magnetic properties

Strong magnetic minerals: dry magnetic separator (low investment, easy maintenance)

Weakly magnetic minerals: high gradient magnetic separator (separation accuracy ±0.5%)

Ultrafine minerals: wet drum magnetic separator + centrifugal concentrator combination

Configuration according to capacity requirements

Small mines (<50t/h): modular design

Large concentrators (>150t/h): fully automatic production lines, supporting 24-hour continuous operation

7. Core Advantages

Customized Solutions

Design separation process based on ore magnetic susceptibility (X) and embedding characteristics

Provide mineral selectivity test and semi-industrial test services

Global service network

EPC general contractor: covering geological analysis-process design-installation and commissioning

English

English

中文

中文