1.Process Overview

Hematite is a weakly magnetic ore, and multiple processes are needed for beneficiation. The efficiency of the traditional single process (roasting magnetic separation, flotation, and strong magnetic separation) is limited, and now combined processes are often used to improve indicators. The mainstream technical routes include:

Roasting magnetic separation process: enhance magnetism through roasting and improve separation efficiency.

Flotation process: separate according to the difference in surface properties of minerals.

Weak magnetic-strong magnetic joint process: process different magnetic minerals in stages.

Strong magnetic flotation joint process: strong magnetic pre-tailing, flotation fine separation.

Gravity-magnetic-flotation joint process: multi-dimensional coordination, adapt to complex ore bodies.

2.Applicable ore body characteristics

This process is applicable to the following types of hematite:

Complex mineral composition: mainly hematite, with associated magnetite, quartz, kaolin, etc.

Uneven distribution of particle size: coarse and fine particles are mixed, with a high proportion of fine particles.

Difficult sorting: multiple processes are required to coordinate desludging, tailings disposal and enrichment.

3. Process advantages

Stage grinding-classification optimization

One stage closed-circuit grinding (ball mill + cyclone) ensures particle size control, and pre-discharging tailings reduces the risk of over-grinding.

High-gradient magnetic separation produces qualified concentrate in advance and reduces the amount of re-grinding of middlings.

Magnetic separation-flotation synergy

Magnetic separation can be collected and discarded early to reduce the amount of flotation processing.

Strong magnetic tailings and mud removal can create a stable pulp environment for flotation.

Reverse flotation reduces costs and improves efficiency

The reagent system is simplified to reduce organic pollution.

The "less flotation and more suppression" strategy reduces reagent consumption and improves concentrate grade.

4. Typical Cases

Case 1: A hematite mine project in the Philippines (700,000 tons per year)

Ore characteristics: mainly fine-grained hematite, containing quartz vein stone.

Process design

Two-stage desludging pretreatment, the sedimentation is subjected to the "one coarse, one fine, three sweeping" process.

The medium ore is returned to the second stage for desludging to enhance the recovery of fine particles.

Result: The concentrate grade is 69.7%, and the recovery rate is 65.4%, exceeding customer expectations.

Case 2: A hematite mine project in Shanxi

Ore characteristics: Magnetite-hematite mixture, uneven distribution of particles, quartz vein.

Process design:

Stage grinding (one stage grinding to obtain 60% coarse concentrate).

Gravity separation to discard coarse tailings, fine-grained strong magnetic-reverse flotation combined tailings.

Results: Concentrate grade 65.95%, tailings grade 10.05%, both excellent technical and economic indicators.

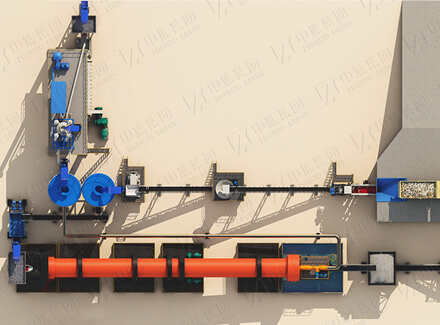

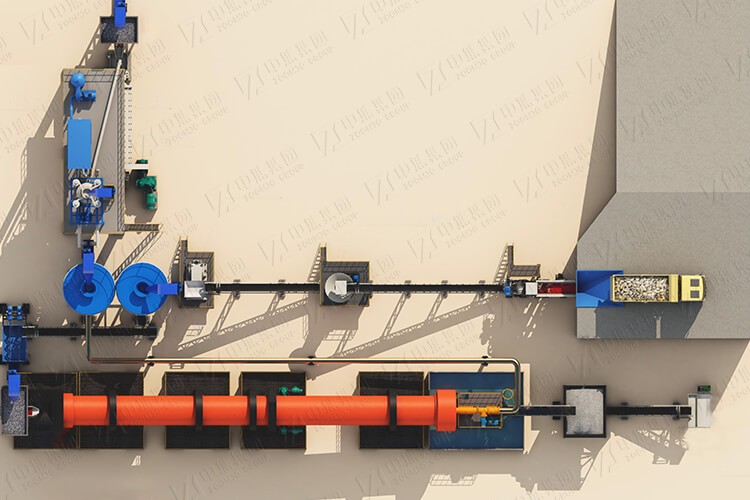

Case 3: Inner Mongolia 2500t/d Iron Ore EPC Project

Core technology:

One stage of closed-circuit grinding + four stages of magnetic separation.

Dual dehydration system for concentrate and tailings (vacuum filtration + cyclone concentration).

Results: Efficient separation of iron ore, moisture content of concentrate < 10%, and dry stacking of tailings meets environmental protection standards.

English

English

中文

中文