1. Process Overview

Gravity separation is based on the difference in mineral density and is separated by gravity, fluid power or mechanical force. It is particularly suitable for the separation of medium and high density minerals such as gold, tungsten, tin and titanium. Through more than 40 years of technological iteration, Zhongjiao has formed a modular gravity separation process system that combines efficient separation with environmental protection advantages. It is suitable for the treatment of coarse, medium and fine-grained minerals, with a recovery rate of 5-15% and a reduction in energy consumption of 20-30%.

2. Applicable ore types and sorting indicators

| Ore type | Typical mineral combinations | Applicable particle size | Recovery rate range |

|---|---|---|---|

| Placerous gold ore | Native gold, magnetite, ilmenite | 0.1 - 1.0mm | ≥90% |

| Wormite ore | Wormite, scheelite, quartz | 0.01 - 15mm | 80 - 85% |

| Cassiterite polymetallic ore | Cassiterite, pyrite, sphalerite | 0.02 - 5mm | 85 - 90% |

| Ilmenite ore | Ilmenite, rutile, zircon | 0.05 - 2mm | 75 - 82% |

| Baryte ore | Baryte, fluorite, galena | 0.1 - 3mm | 88 - 93% |

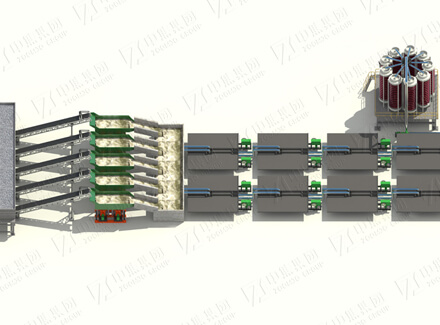

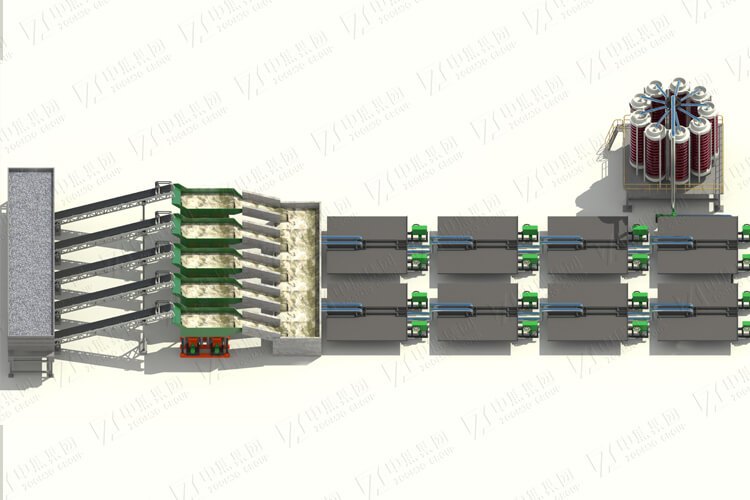

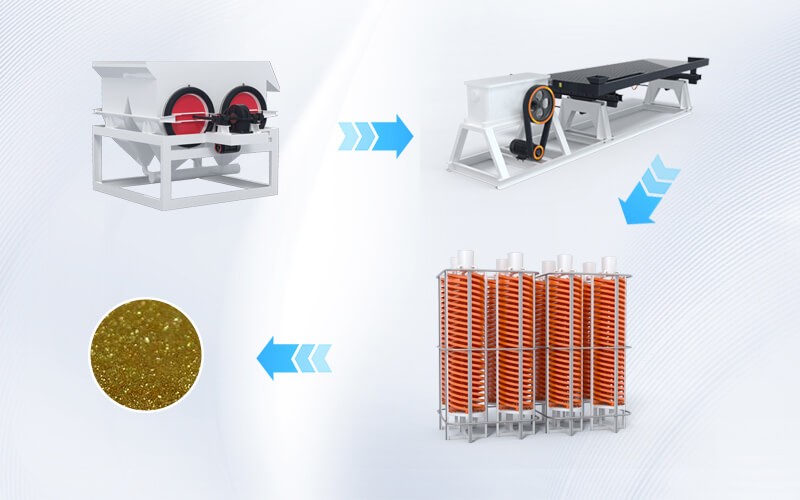

3. Core process flow

Pretreatment stage

Crushing and screening: jaw crusher (feed ≤ 500mm) + circular vibrating screen (grading accuracy ±1mm)

Washing and desludging: spiral ore washer (desludging rate ≥ 95%)

Sorting stage

| Process type | Equipment configuration | Applicable scenarios |

|---|---|---|

| Jig separation | Jig (processing capacity 10 - 50t/h) | Rapid pre - enrichment of coarse - grained minerals (>0.5mm) |

| Shaking table separation | 6 - S shaker (processing capacity 0.5 - 2t/h) | Purification of medium - fine - grained minerals (0.1 - 2mm) |

| Centrifugal separation | Centrifugal concentrator (processing capacity 5 - 20t/h) | Enhanced recovery of fine - grained minerals (0.02 - 0.1mm) |

| Heavy medium separation | Heavy medium cyclone (density adjustment accuracy ±0.1) | Pre - disposal of complex embedded ores |

Post-processing stage

Dehydration and drying: high-efficiency concentrator (underflow concentration ≥ 65%) + rotary dryer (water content ≤ 8%)

Tailings management: dry storage or preparation of building materials (utilization rate ≥ 30%)

4. Typical Customer Cases

Sudan 500t/d gold mine project

| Project parameters | Design value | Implementation effect |

|---|---|---|

| Ore grade | 0.811g/m³ | Raw gold grade 85%, recovery rate 93.38% |

| Process flow | Two-stage jigging (LTA1010/2) + shaking table selection (6-S) | Water saving 40%, energy consumption reduced 25% |

| Environmental protection measures | Circulating water system (recycling rate ≥85%) | Heavy metal leaching concentration of tailings <0.1mg/L |

5. Technical advantages

Efficient sorting

Particle size adaptation: covering all particle sizes from 0.02 to 15 mm, with a recovery rate 5-10% higher than traditional processes.

Energy saving and consumption reduction

Modular design reduces the number of equipment by 30% and the installed power by 25%.

Energy consumption per ton of ore for heavy medium separation ≤1.5kWh.

Environmental compliance

Dry tailings discharge technology (water content ≤ 15%).

Reduction of reagent dosage by 50% (cyanide-free and non-toxic inhibitors).

Flexible expansion

Supports customization from 100t/d small line to 5000t/d large line.

Quickly switch the separation medium (ferrosilicon/magnetite powder) to adapt to multiple mineral types.

6. Equipment selection recommendation

| Equipment type | Processing capacity | Applicable scenarios |

|---|---|---|

| Jig | 10 - 50t/h | Pre-selection of coarse-grained gold and tungsten ores |

| Centrifugal concentrator | 5 - 20t/h | Recovery of fine-grained tin and titanium ores |

| Heavy medium cyclone | 50 - 100t/h | Pre-disposal of complex polymetallic ores |

| 6-S shaker | 0.5 - 2t/h | Selection of medium- and fine-grained minerals |

Note: This solution supports EPC general contracting services, covering mineral selectivity testing, process design, equipment installation and commissioning, and operation training, and provides recovery rate guarantees, helping customers achieve the goal of maximizing resource value and building green mines.

English

English

中文

中文