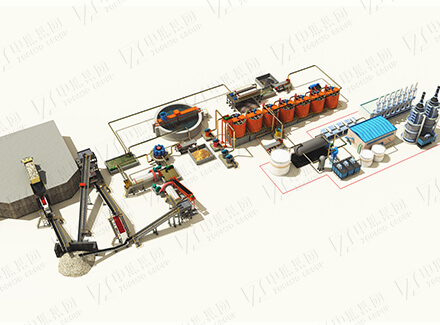

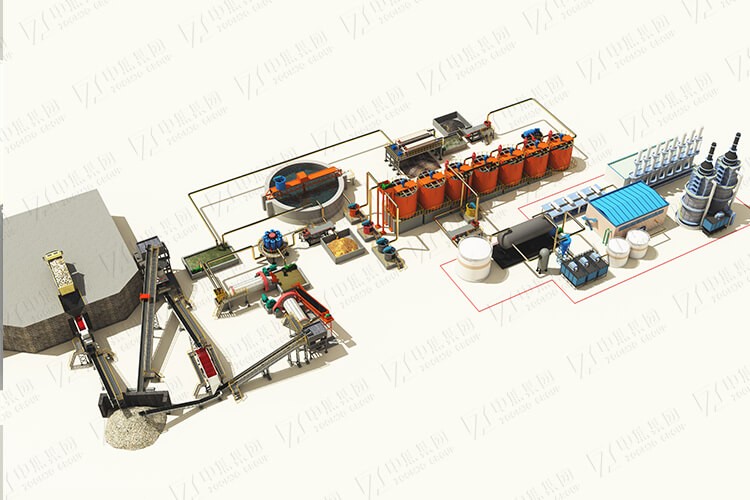

1. Process Overview

CIP (carbon-in-pulp process) is an efficient gold extraction process, specially designed for flotation of gold concentrate, high-mud oxidized gold ore and amalgam/gravity separation tailings. It achieves a gold recovery rate of ≥96% and a concentrate grade of ≥98% by adsorbing gold ions in cyanide slurry with activated carbon. Compared with traditional processes, this solution eliminates the solid-liquid separation link, reduces investment costs by 30-50%, reduces production costs by 8-35%, and is suitable for 1-5000t/d scale concentrators.

2.Core process flow

| Process stages | Technical points | Key equipment | Technical parameters |

|---|---|---|---|

| 1. Pretreatment | - Slurry screening (removal of impurities > 0.3 mm) | High-frequency vibrating screen | Screening efficiency ≥95%, processing capacity 50 - 200t/h |

| - Activated carbon pretreatment (rounded corners, particle size 1 - 3 mm) | Activated carbon grinder | Carbon loss rate ≤2%, processing capacity 5t/h | |

| 2. Leaching and adsorption | - Cyanide leaching (NaCN concentration 0.03 - 0.08%) | High-efficiency cyanide leaching tank | Leaching rate ≥95%, adsorption cycle 6 - 12h |

| - Dynamic adsorption of coconut shell activated carbon (gold loading 6 - 10 kg/t) | Carbon screen | Sieve gap 0.8mm, carbon slurry separation efficiency ≥99% | |

| 3. Analytical electrolysis | - High temperature and high pressure desorption (150°C, 0.5 MPa) | Desorption and electrolysis integrated machine | Desorption rate ≥99%, electrolysis efficiency ≥98% |

| - Direct electrolysis of precious liquid to produce gold mud | High-frequency gold melting furnace | Gold ingot purity ≥99.9%, energy consumption ≤15kWh/kg | |

| 4. Carbon regeneration | - Acid washing (5% dilute sulfuric acid) + thermal activation (650°C) | Activated carbon regeneration furnace | Iodine value recovery rate ≥95%, carbon cycle times ≥10 times |

3. Technical advantages

High-efficiency adsorption system

Coconut shell activated carbon: adsorption capacity ≥1000g/t, wear resistance ≥95%, 20% higher adsorption capacity than apricot kernel carbon.

Fluidization design: slurry flow rate in the adsorption tank is 0.8-1.2m/s to avoid carbon deposition.

Energy saving and consumption reduction

Heat recovery: waste heat from desorption is used to preheat the slurry, saving 30% energy.

Closed-circuit water circulation: cyanide wastewater reuse rate ≥ 95%, new water consumption ≤ 0.5t/t ore.

4. Equipment configuration plan (taking 500t/d concentrator as an example)

| Equipment name | Model | Quantity | Key parameters |

|---|---|---|---|

| Cyanide leaching tank | XH-JC-500 | 8 | Single tank volume 50m³, power 11kW |

| Carbon screen | GKS-1200 | 4 | Processing capacity 120t/h, screen area 12㎡ |

| Desorption and electrolysis integrated machine | XH-JX-200 | 2 | Desorption cycle 4h, electrolysis current density 15A/m² |

| Activated carbon regeneration furnace | XH-ZS-10 | 1 | Processing capacity 1t/h, gas consumption 40m³/h |

| High-frequency gold melting furnace | XH-MJ-50 | 1 | Smelting capacity 50kg/h, temperature 1200℃ |

English

English

中文

中文