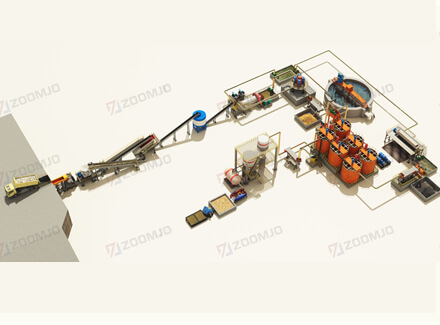

1. Process Overview

CIL (carbon-on-leach) is a gold extraction process that combines cyanide leaching with activated carbon adsorption. It is suitable for high-grade gold mines and polymetallic mines with associated silver and copper, and is especially suitable for 500-5000t/d scale concentrators. Compared with the traditional CIP process, CIL combines leaching and adsorption into one step, shortening the process cycle by 30-50%, reducing the backlog of gold retention by 20-30%, and reducing the overall investment cost by 40-60%. The typical recovery rate is ≥91.5%, and the purity of gold ingots is ≥99.9%.

2. Core process flow

| Process stages | Technical points | Key equipment | Technical parameters |

|---|---|---|---|

| 1. Cyanide leaching | - Stepped leaching tank | High-efficiency cyanide leaching tank | Single tank volume 60m³, leaching rate ≥95% |

| - NaCN concentration 0.03 - 0.06% | Central aeration lifting pipe | Power consumption reduced by 70%, slurry suspension uniformity ≥90% | |

| 2. Carbon adsorption | - Dynamic adsorption of coconut shell activated carbon (gold loading 8 - 12kg/t) | Carbon screen | Screen gap 1.0mm, carbon loss rate ≤1% |

| - Synchronous adsorption of associated silver and copper (recovery rate ≥80%) | Hydraulic filter press | Filter cake moisture content ≤18%, processing capacity 200t/h | |

| 3. Desorption electrolysis | - High temperature and high pressure desorption (150℃, 0.5MPa) | Desorption and electrolysis integrated machine | Desorption rate ≥99%, electrolysis efficiency ≥98% |

| - Direct electrolysis of precious liquid to produce gold mud | High-frequency gold melting furnace | Gold ingot purity ≥99.9%, smelting capacity 100kg/h | |

| 4. Carbon regeneration | - Acid washing (3% dilute nitric acid) + thermal activation (650℃) | Activated carbon regeneration furnace | Iodine value recovery rate ≥96%, carbon cycle times ≥15 times |

3. Technical advantages

Efficient collaboration

Synchronous leaching and absorption: shorten the process cycle to 18-24 hours, reduce the backlog of gold retention funds by 20-30%.

Associated metal recovery: the comprehensive recovery rate of silver and copper is increased by 15-25%.

Cost optimization

Investment savings: 66% less than the traditional CCD process, 30% less infrastructure cost than the CIP process.

Low consumption of activated carbon: regeneration technology reduces the amount of new carbon by 70%, and the carbon consumption per ton of ore is ≤0.1kg.

Energy saving and environmental protection

Waste heat utilization: desorption waste heat preheats the slurry, saving 25% energy

Tail liquid treatment: hydrogen peroxide cyanide breaking process, total cyanide concentration ≤ 0.2mg/L

4. Typical case: Tanzania 1200t/d gold mine project

| Project parameters | Design value | Implementation effect |

|---|---|---|

| Ore grade | Au 7.5g/t, Ag 15g/t | Gold leaching rate 91.5%, silver recovery rate 83% |

| Process flow | CIL carbon leaching method | Saving investment of $486,000/year compared with CIP |

| Key equipment | Leaching tank + desorption system | Power consumption per ton of ore ≤18kWh, carbon loss rate ≤1% |

| Environmental benefits | Tail liquid cyanide concentration ≤ 0.2mg/L | Passed ISO 14001 certification |

5. Equipment configuration plan (taking 1200t/d concentrator as an example)

| Equipment name | Quantity | Key parameters |

|---|---|---|

| Cyanide leaching tank | 9 | Single tank volume 60m³, gas filling volume 0.8m³/(m²·min) |

| Carbon screen | 6 | Processing capacity 150t/h, screen surface area 15㎡ |

| Desorption and electrolysis integrated machine | 3 | Desorption cycle 4h, current density 20A/m² |

| Activated carbon regeneration furnace | 2 | Processing capacity 2t/h, gas consumption 80m³/h |

| High-frequency gold melting furnace | 2 | Smelting capacity 100kg/h, temperature 1250℃ |

English

English

中文

中文