1. Process Overview

Gold flotation is the core process of rock gold ore beneficiation. It enriches fine gold in sulfide minerals through physical and chemical methods. It is suitable for sulfide gold-bearing quartz vein ores and polymetallic gold-bearing sulfide ores, especially for gold minerals with fine embedded particle size (0.01-0.1mm). This scheme adopts staged grinding and flotation process, and achieves gold recovery rate ≥90%, concentrate grade ≥30g/t, and tailings gold loss ≤0.5g/t by optimizing reagent system and process design.

2. Core Process System

Crushing and grinding

Coarse crushing: jaw crusher (feed size ≤500mm → discharge size ≤100mm).

Fine grinding: ball mill + cyclone closed-circuit classification (grinding fineness: -200 mesh accounts for 85-95%).

Stage grinding and flotation: coarse grinding (-200 mesh 65%) → flotation tailing → regrinding (-200 mesh 90%) → concentrating

Flotation process

| Agent type | Function | Recommended agents | Dosage (g/t) |

|---|---|---|---|

| Collector | Selective adsorption of gold minerals | Butyl xanthate/black medicine (Z - 200) | 50 - 150 |

| Activator | Enhance the surface activity of sulfide minerals | Copper sulfate | 100 - 300 |

| Foamer | Stabilize the foam structure | Pinpineol/MIBC | 20 - 50 |

| Inhibitor | Inhibit impurities such as arsenic and antimony | Lime/sodium sulfide | 500 - 1500 |

3. Key technical parameters

| Index items | Design range | Key points of control |

|---|---|---|

| Grinding fineness | -200 mesh accounts for 85 - 95% | Adjust in stages according to the characteristics of gold embedding |

| Slurry concentration | Roughing 30 - 40%, fine selection 20 - 25% | Roughing high concentration to ensure recovery, and fine selection of low concentration to improve quality |

| Flotation time | Roughing 5 - 8min, fine selection 3 - 5min | Adjust the level of the flotation machine and the amount of aeration in a linkage manner |

| pH value control | 8.5 - 10.5 (lime adjustment) | Inhibit pyrite oxidation and reduce reagent consumption |

4. Typical case: a gold mine renovation project in Yunnan

Ore characteristics

Ore type: Arsenic-antimony pyrite type fine-grained gold ore

Ore grade: 3.30g/t

Pain point: Arsenic-antimony mineral adsorption agent, low flotation efficiency

Transformation plan

Process optimization:

Stage grinding and flotation: coarse grinding (-200 mesh 65%) → flotation tailing → regrinding (-200 mesh 92%) → enhanced selection

Equipment upgrade: cyclone replaces spiral classifier, flotation column enhances sweeping

Adjustment of reagents:

Add combined inhibitor (lime + sodium humate) to inhibit arsenic and antimony

Use high-efficiency collector (Y89 + ammonium butyl black medicine) to improve selectivity

Transformation effect

| Indicators | Before renovation | After renovation | Improvement |

|---|---|---|---|

| Concentrate grade (g/t) | 33.35 | 34.38 | 0.031 |

| Gold recovery rate (%) | 81.8 | 90.62 | 0.108 |

| Tailing loss (g/t) | 0.68 | 0.34 | -0.5 |

5. Technical advantages

Efficient recovery: stage grinding and flotation + combined reagents, gold recovery rate increased by 10-15%

Precise control of impurities: Arsenic and antimony suppression efficiency ≥ 85%, concentrate impurity content ≤ 1%

Energy saving and consumption reduction:

Cyclone classification efficiency ≥ 90%, mill power consumption reduced by 20%

Flotation column sweeping section saves 30% of reagent usage

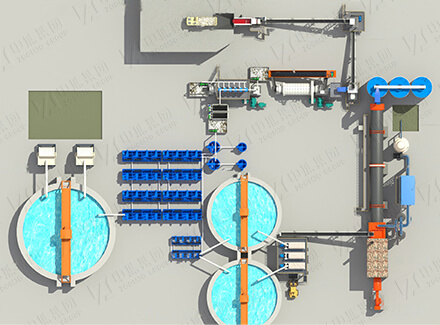

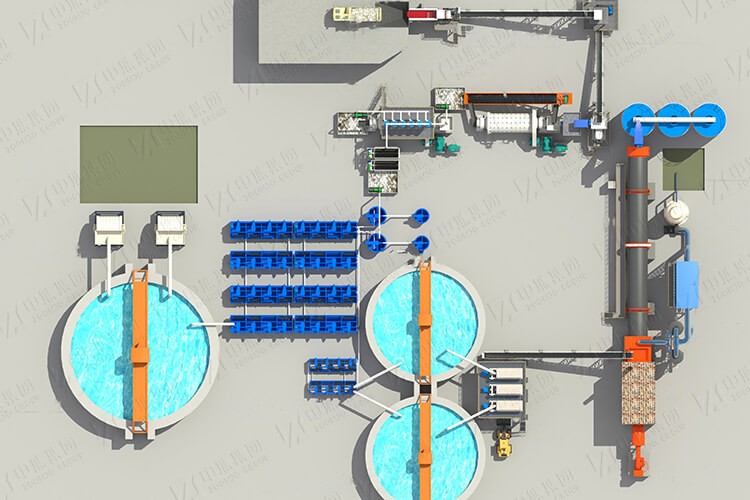

6. Equipment configuration recommendation

| Process section | Core equipment | Key parameters |

|---|---|---|

| Crushing | Jaw crusher | Processing capacity 56t/h, power 55kW |

| Grinding | Ball mill + cyclone group | System processing capacity 300t/d, circulation load ≤200% |

| Floatation | Flotation machine + flotation column | Single tank volume 24m³, aeration volume 1.5m³/(m²·min) |

| Dewatering | High - efficiency concentrator + plate and frame filter press | Filter cake moisture content ≤15% |

7. Selection and Service

Customized design:

Match the number of grinding and flotation stages according to the ore embedding characteristics (clear gold/encapsulated gold)

Special reagent solution for high arsenic antimony ore (environmentally friendly inhibitor)

EPC general contractor:

Including mineral selectivity test, process design, equipment installation and commissioning.

Provide operation training.

Note: This solution supports the green mine upgrade option, which can integrate the wastewater recycling system (reuse rate ≥ 95%) and the tailings dry discharge module to help pass the environmental impact assessment.

English

English

中文

中文