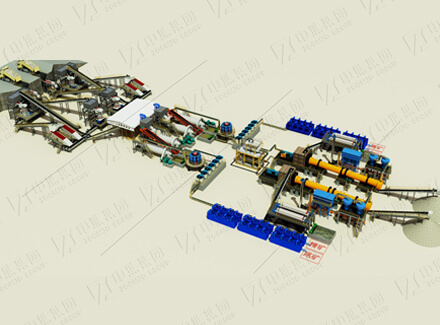

1. Process Overview

The core of copper ore dressing is flotation, which achieves efficient enrichment of copper minerals through crushing, grinding, flotation, concentration, dehydration and other processes. For sulfide ores, oxide ores and complex associated ore bodies, ZOOMJO GROUP adopts customized process design, combined with advanced equipment and reagent optimization, the copper recovery rate can reach 85%-95%, and the concentrate grade is >20%.

2. Core process flow

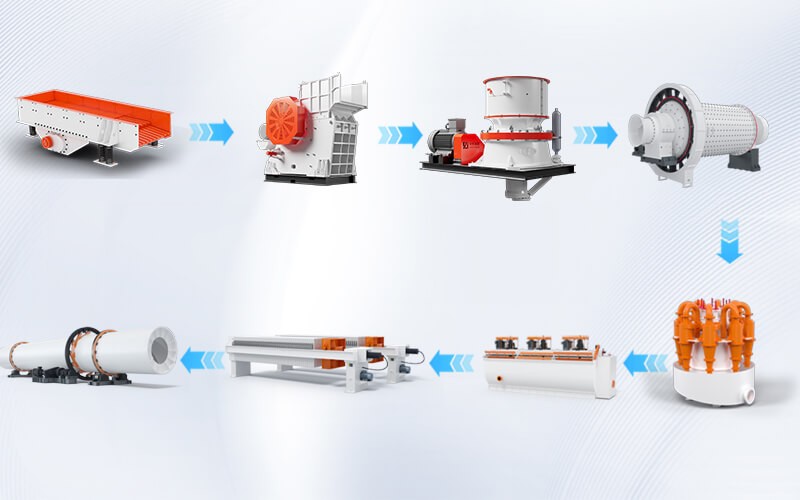

1. Crushing stage

Coarse crushing: The jaw crusher crushes the raw ore to 100-200mm, with a processing capacity of 8000t/d.

Medium and fine crushing: The cone crusher performs multi-stage closed-circuit crushing, producing a uniform particle size of 10-30mm, reducing the energy consumption of grinding.

2. Grinding and Classification

Equipment configuration: ball mill + spiral classifier/cyclone group closed-circuit system, precise control of grinding fineness (-0.074mm accounts for 85%-90%).

Technical highlights:

Cyclone classification efficiency> 80%, reducing over-grinding;

Frequency conversion ball mill saves 15%-20% energy.

3. Flotation separation

Slurry optimization:

Collector: xanthate (such as amyl xanthate) targets copper minerals for adsorption;

Frother: MIBC regulates foam stability;

Adjuster: lime controls pulp pH (8-10) and inhibits pyrite.

Flotation process:

Roughing: 80% copper minerals are quickly floated out, and the grade of the rough concentrate is 5%-8%;

Fine selection: 2-3 fine selections, the concentrate grade is increased to 20%-30%;

Scavenging: tailings are refloated, and the copper recovery rate is increased by 5%-8%.

4. Concentration and dehydration

Concentration: high-efficiency thickener sedimentation, the moisture content of the concentrate is reduced to 30%-50%;

Dehydration:

Chamber filter press: moisture content ≤15%;

Dryer (optional): moisture content of the concentrate is<10%, meeting the smelting requirements.

5. Tailings treatment

Dry discharge technology: cyclone + dewatering screen combined process, tailings water content<15%, can be used as a resource;

Environmental protection return water: return water rate ≥85%, achieving zero discharge.

3. Key equipment configuration

| Process stages | Core equipment | Technical advantages |

|---|---|---|

| Crushing | Jaw crusher, cone crusher | High processing capacity, low failure rate |

| Grinding | Energy-saving ball mill, cyclone group | Precise particle control, energy consumption reduced by 20% |

| Floatation | Aerated mechanical agitator flotation machine | Even distribution of bubbles, recovery rate increased by 8% |

| Dehydration | Automatic chamber filter press, drum dryer | Efficient dehydration, low operation and maintenance costs |

| Environmental protection | Bag dust collector, tailings dry discharge system | Dust concentration 10mg/m³, green compliance |

4. Technical advantages and benefits

High-efficiency flotation system:

Copper concentrate grade>25%, recovery rate≥90% (sulfide ore);

Oxide ore adopts sulfide flotation + activator, and the recovery rate is increased to 75%-85%.

Energy-saving and consumption-reducing design:

The energy consumption of the entire process is reduced by 25%, and the cost per ton of ore is saved by 10-15 yuan;

The life of the equipment is extended by 30%, and the maintenance cost is reduced by 20%.

Resource recycling:

Tailings are used to make building materials (such as bricks and cement aggregates), increasing added value by 50%;

The wastewater recycling system saves 1 million m³ of water annually.

5. Production Example: A Large Copper Mine Project in Peru (8000t/d)

Ore characteristics: Contains 0.8% copper, accompanied by molybdenum and gold, and the embedded particle size is uneven.

Process solution:

Stage grinding and flotation: coarse grinding and discarding tailings (-0.15mm) → fine grinding and selection (-0.074mm accounts for 90%);

Copper and molybdenum separation: coarse concentrate regrinding + inhibitor (sodium hydrosulfide) preferentially floats molybdenum.

Results:

| Indicators | Ore grade | Concentrate grade | Recovery rate |

|---|---|---|---|

| Copper (%) | 0.8 | 28.5 | 92.3 |

| Molybdenum (%) | 0.02 | 45.6 | 68.7 |

| Gold (g/t) | 0.35 | 12.5 | 63.2 |

Benefits: Annual output value exceeds 1.5 billion yuan, and tailings resource utilization generates revenue of 30 million yuan per year.

With the goal of "fine sorting and full utilization of resources", ZOOMJO GROUP provides EPC general contracting services for copper ore dressing, covering sulfide ores, oxide ores and polymetallic associated ores. It has more than 200 successful cases worldwide, helping customers achieve a win-win situation of economic benefits and environmental responsibility.

English

English

中文

中文