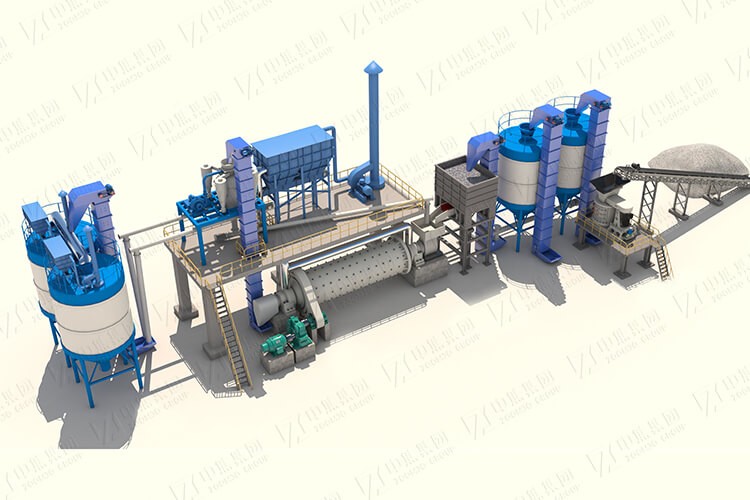

1. System Overview

The cement grinding station is the core unit of cement product production, which is dedicated to the fine grinding of clinker and additives such as gypsum and slag to form cement products that meet the GB/T 21372 standard. The designed production capacity is 25-195 t/h, supporting the production of various cement varieties such as PO, PC, PP, etc., adapting to the layout of urban suburbs, reducing storage and transportation costs, and meeting the large-scale production needs of 1000-6000 tons/day.

2. Core Process System

Closed-circuit grinding process

Process: clinker pre-crushing (≤25mm) → batching system (accurate proportion of gypsum/slag) → ball mill grinding → high-efficiency powder classifier classification (finished product fineness ≤45μm) → pulse dust collection → automatic packaging

Advantages:

20-30% energy saving compared to open circuit system

Surface area of finished product 350-450 m²/kg controllable

Particle size uniformity (R45μm sieve residue ≤12%)

Key equipment configuration

| Equipment module | Functional characteristics |

|---|---|

| Ball mill | Double sliding shoe support, loading capacity 210-230t |

| Roller press | Pre-grinding system, crushing power consumption ≤3.5kWh/t |

| High-efficiency powder separator | Classification efficiency ≥85%, fineness adjustment accuracy ±2% |

| Pulse dust collector | Emission concentration ≤10mg/m³ |

| Automatic packaging machine | Dual-mouth packaging, accuracy ±0.5kg |

3. Energy consumption optimization

Energy-saving technology:

Pre-grinding system: roller press + dynamic powder selector combination to reduce the load of ball mill

Grinding aid addition: reduce over-grinding and increase output by 15-25%

Intelligent water spray cooling: temperature control in the mill ≤120℃ to prevent gypsum dehydration

4. Detailed explanation of core equipment

Ball mill

Powder Classifier

Three-stage sorting:

Centrifugal pre-classification (removal of particles > 150μm)

Eddy current fine classification (core area wind speed 4-6m/s)

Dynamic adjustment (variable frequency motor accuracy 0.1Hz)

Dust removal system

Three-stage filtration:

Cyclone pre-dust collection (efficiency ≥ 80%)

Pulse bag filter

Exhaust humidity control (dew point ≤ 45℃)

5. Typical customer case

Southeast Asia 300,000 tons/year cement grinding station

Configuration: Φ4.6×14m ball mill + roller press

Results:

Power consumption reduced to 29.5kWh/t

Specific surface area qualified rate>98%

Automation degree reached 85%, operators reduced by 40%

6. Core Advantages

Customized design

Customize mill aspect ratio and powder selector parameters according to raw material characteristics (clinker grindability, mixed material types)

Support EPC general package, including process design-equipment installation-production training

Increase efficiency and reduce costs

Pre-grinding process: electricity consumption per ton of cement is reduced by 8-12kWh

Wear-resistant technology: long liner life, steel consumption ≤50g/t

English

English

中文

中文