1. System Overview

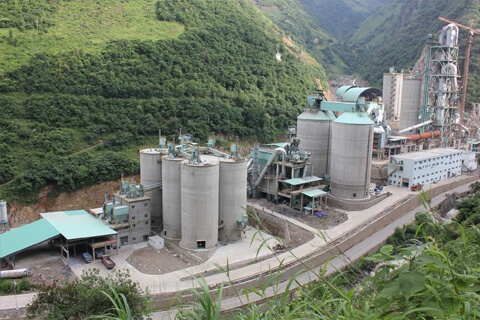

This solution is a new dry process cement production line with a designed clinker capacity of 1000 t/d. It adopts the core technology of five-stage cyclone preheater + decomposition furnace + rotary kiln + grate cooler, and is suitable for raw materials such as limestone, clay, and iron ore.

2. Core technology and equipment configuration

| Process section | Core equipment | Key technical parameters |

|---|---|---|

| Raw material crushing | Single-stage hammer crusher | Processing capacity 100-140t/h, discharge ≤75mm |

| Raw material drying | Dryer | Processing capacity 100-140t/h, discharge ≤75mm |

| Raw material preparation | Closed-circuit raw material ball mill | Production capacity 45-55t/h, specific surface area ≥3200cm²/g |

| Powdered coal preparation | Air-swept steel ball coal mill | Production capacity 5.5-7.6t/h, fineness R80μm≤12% |

| Clinker calcination | Rotary kiln + five-stage preheater system | Heat consumption ≤3400 kJ/kg, decomposition rate ≥90% |

| Clinker cooling | Monocular cooler | Discharge temperature ≤65℃+ambient temperature, heat recovery rate ≥60% |

| Cement grinding | High-yield and high-fine cement ball mill | Production capacity 27-31t/h, specific surface area ≥3600cm²/g |

| Environmental governance | Pulse bag dust collector + denitrification system | Dust ≤20mg/Nm³, NOx ≤320mg/Nm³ |

3. Process highlights

Efficient raw material pretreatment

Single-stage crushing: Hammer crusher can crush limestone to ≤75mm in one step, reducing equipment investment by 15%

Dynamic homogenization: Raw material pre-homogenization yard capacity ≥3 days of consumption, homogenization coefficient ≥8

Intelligent calcination control

Five-stage preheater: C1 outlet exhaust gas temperature ≤320℃, system pressure loss ≤5000Pa

Decomposition furnace fuel substitution: support biomass fuel (substitution rate ≥15%), CO₂ emission reduction 10%

Energy-saving grinding technology

Closed-circuit raw material mill: Powder classifier efficiency ≥85%, circulation load ≤150%

High-fine cement mill: 3-32μm particles account for ≥65%, hydration activity increased by 20%

Environmental protection in-depth treatment

Multi-stage dust removal: cyclone dust removal (efficiency ≥ 80%) + bag dust removal (emission ≤ 20mg/Nm³)

SNCR denitrification: ammonia consumption ≤ 3.5kg/t clinker, NOx emission reduction efficiency ≥ 50%

4. List of core equipment

| Equipment name | Quantity | Key parameters |

|---|---|---|

| Single-stage hammer crusher | 1 | Power 200kW, processing capacity 140t/h |

| Rotary kiln | 1 | Slope 3.5%, speed 0.5 - 3.0r/min |

| Five-stage cyclone preheater | 1 set | System thermal efficiency ≥55% |

| Grate cooler | 1 | Secondary air temperature ≥1000℃ |

| Cement ball mill | 1 | Main motor power 1000kW |

| Packaging machine | 2 | 8-mouth rotary, accuracy ±0.5kg |

English

English

中文

中文