West Africa Mali Gold Mine Flotation Production Line Project

The gold ore in Mali's Kayes region is primarily composed of arsenic-bearing fine-grained disseminated gold ore. Traditional all-sliming cyanidation faces key challenges:1. Gold particles encapsulated in arsenopyrite/pyrite, direct leaching rate <50%; 2. Fine grinding energy consumption as high as 35kWh/t, keeping beneficiation costs elevated.

Project Background

The gold ore in Mali's Kayes region is primarily composed of arsenic-bearing fine-grained disseminated gold ore. Traditional all-sliming cyanidation faces key challenges:

Gold particles encapsulated in arsenopyrite/pyrite, direct leaching rate <50%

Fine grinding energy consumption as high as 35kWh/t, keeping beneficiation costs elevated

ZOOMJO MINING MACHINERY adopted an innovative multi-stage grinding & stepwise flotation solution, achieving three breakthroughs:

Liberation of Disseminated Gold: Stage grinding ensures full exposure of gold particles

Arsenic-Gold Separation: Developed a novel depressant for selective suppression of arsenopyrite

Energy Savings: Applied high-pressure roller mill to reduce crushing/grinding energy consumption by 28%

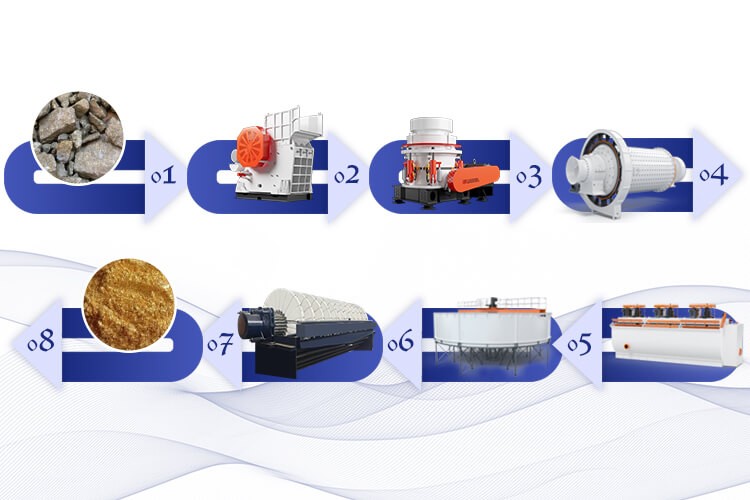

Core Production Line Process

1. Crushing & Pre-Treatment System

Coarse Crushing: JC Jaw Crusher (Capacity 680t/h, Output ≤120mm)

Fine Crushing: Secondary crushing via cone crusher

2. Stage Grinding Section

Primary Grinding: Ball Mill (Capacity 85t/h, Discharge Size -0.074mm 65%)

Secondary Grinding: Closed-circuit with hydrocyclone & Φ3.6×6m overflow ball mill (Final Fineness -0.038mm 90%)

3. Flotation Enrichment System

Roughing: KYF-16 Flotation Units (Collector: Dibutyl ammonium dithiophosphate + MIBC)

Cleaning: Combined flotation column & mechanical flotation (3-stage cleaning to upgrade concentrate grade)

Scavenging: Middlings regrinding system (Ultra-fine grinding to -0.020mm via vertical mill)

4. Concentrate Treatment Section

Thickening: High-efficiency deep cone thickener (Underflow Density ≥65%)

Dewatering: Ceramic filter (Concentrate Moisture ≤12%)

Smelting: Direct supply to bio-oxidation pretreatment plant (Gold leaching rate increased to 96%)

Project Achievements

Annual Gold Production Increase: 1.2 tons (Based on 330 operating days/year)

Cut-off Grade Reduced from 1.8g/t to 1.2g/t, Improving Resource Utilization by 33%

Tailings Arsenic Leaching Concentration <0.01mg/L, Meeting ICMM Environmental Standards

English

English

中文

中文