Jizan Industrial City Project, Saudi Arabia

The intelligent sand dryer of ZOOMJO GROUP has completely changed our production pattern! Under the extreme environment of 50℃ high temperature and frequent sandstorms, the continuous operation rate of the equipment reaches 99.8%, the thermal efficiency is increased to 82%, and the energy consumption of tons of sand is reduced to 18kW-h.

Customer Feedback

“The intelligent sand dryer of ZOOMJO GROUP has completely changed our production pattern! Under the extreme environment of 50℃ high temperature and frequent sandstorms, the continuous operation rate of the equipment reaches 99.8%, the thermal efficiency is increased to 82%, and the energy consumption of tons of sand is reduced to 18kW-h. ”

-- Khalid Al-Mansoori, Technical Director, Arabian Sands, Saudi Arabia

Equipment Core Advantages

Extreme climate adaptation:

Cylinder body is coated with nano insulating ceramic, reducing surface temperature by 45°C

Electrical system IP68 certified to resist sand and dust intrusion (PM10 concentration ≤ 2000μg/m³ environment)

Energy saving revolution:

Integrated three-stage waste heat recovery device, waste heat utilization rate of exhaust gas ≥ 75

Gas-fired hot air furnace supports LNG/solar complementary heating, reducing carbon emissions by 40%.

Production Line Configuration

| Equipment | Technical Parameters |

|---|---|

| Intelligent vibrating feeder | Capacity 800t/h, temperature resistance 70°C |

| High-efficiency three-cylinder dryer | Φ3.2×20m, LNG heat consumption≤35m³/t sand |

| Pulse bag filter | Filter area 1280m², emission <5mg/m³ |

| Sand shaper | The sphericity coefficient is increased to 0.92±0.02 |

| Intelligent sorting system | 5 levels of particle size sorting, precision ±0.1mm |

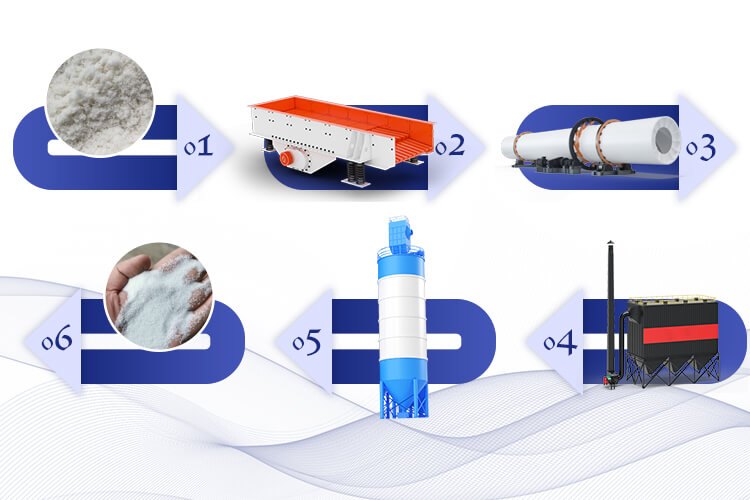

process

Raw material pretreatment:

Raw desert sand is removed from salt (Cl- content<0.01%) by="" screw="" sand="" washer="">

Water content reduced from 15% to 8% by high frequency dewatering screen

Gradient drying:

Wet sand is fed into the three-cylinder dryer from the feeder

Adopting counter-current + down-flow composite heat exchange process:

First zone (120-180 ℃): rapid evaporation of surface water

Second zone (80-120 ℃): the depth of the removal of water of crystallization

Third zone (50-80 ℃): slow Su homogenization treatment

Precision sorting:

Dried sand enters the shaper to enhance sphericity

Output through sorting system:

20-40 mesh (frac sand)

40-70 mesh (glass raw material)

70-140 mesh (3D printing sand)

Intelligent warehousing:

Finished sand enters the constant humidity silo through pneumatic conveying system.

Robot automatic palletizing, with a daily shipping capacity of 5,000 tons.

English

English

中文

中文