Jiangxi 800 tons per hour granite sand production line case

Granite is a high-hardness raw material (Mohs hardness 6-7), which has extremely high requirements for crushing equipment. ZOOMJO GROUP engineers innovatively adopted the "three-stage crushing + two-stage shaping" process to ensure the excellent quality of 0-5mm fine machine-made sand in view of the characteristics of raw materials ≤1000mm:

Customer Background

Ganzhou, Jiangxi, as an important building materials production base in East China, has rich reserves of granite resources. In 2022, local entrepreneur Mr. Chen invested in the construction of a granite sand production line with an output of 800 tons per hour. The full set of equipment was provided by Henan ZOOMJO GROUP Machinery with professional solutions. After a year and a half of stable operation, the production line has become a benchmark supplier of high-standard machine-made sand in southern Jiangxi, and its products are widely used in high-end fields such as high-speed rail and commercial concrete mixing stations.

Project Overview

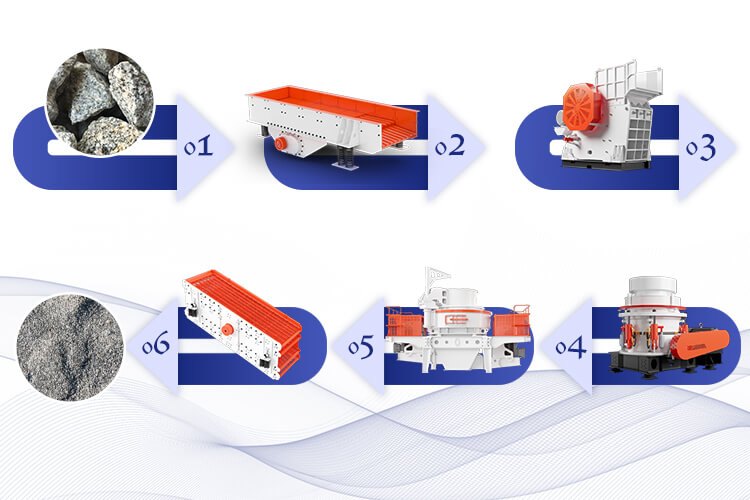

Granite is a high-hardness raw material (Mohs hardness 6-7), which has extremely high requirements for crushing equipment. ZOOMJO GROUP engineers innovatively adopted the "three-stage crushing + two-stage shaping" process to ensure the excellent quality of 0-5mm fine machine-made sand in view of the characteristics of raw materials ≤1000mm:

Process

Coarse crushing stage

The raw materials are evenly fed into the PE1200×1500 jaw crusher through the ZSW600×1600 heavy-duty vibrating feeder and crushed to 250-300mm.

Secondary crushing stage

Secondary crushing is carried out by HPG400 hydraulic cone crusher, and the particle size of the output is controlled at 30-50mm.

Fine crushing and shaping

Two sand making machines are used for vertical shaft impact crushing to achieve "stone hitting stone" + "stone hitting iron" dual-mode sand making.

Screening, washing and grading

3YK3080 high-frequency screen: three-level precise screening

XS3620 bucket sand washer: adjustable powder content (3-10%)

Core device configuration

| Equipment type | Model | Technical advantages |

|---|---|---|

| Vibrating feeder | ZSW600×1600 | Dual motor drive, feeding capacity 800t/h |

| Jaw crusher | PE1200×1500 | Cast steel movable jaw, life extended by 40% |

| Cone crusher | HPG400 | Intelligent hydraulic system, automatic adjustment of discharge port |

| Sand making machine | VX-1263×2 | Quick change design of peripheral guard plate, convenient maintenance |

| Circular vibrating screen | 3YK3080 | German technology bearing, long screen life |

| Sand washing and recovery system | XS3620+Fine sand recovery machine | Sand loss rate<5%<> |

Operational data

Energy consumption control

1.8 kWh per ton (industry average 2.3 kWh)

Finished product quality:

Fineness modulus 2.6-3.0 adjustable

Stone powder content can be controlled at 5-15%

Crushing index<14%>

Economic benefits:

Daily output 6,500 tons

Net profit 25-35 yuan per ton

Customer Testimonials

"ZOOMJO GROUP's production line completely overturned our understanding of granite sand making. Not only did the output exceed expectations, but most importantly, the finished sand could be sold for 8-10 yuan more per ton at the local commercial mixing station. After the equipment was put into operation for 18 months, the lining of the cone crusher was replaced for the first time, which truly achieved high production and low consumption!" - Mr. Chen, Ganzhou Building Materials

ZOOMJO GROUP provide:

✔ Free raw material testing ✔ 3D design of production lines ✔ Operator training ✔ 24-hour technical support throughout the year ✔ Spare parts supply guarantee

Conclusion

The successful implementation of this project marks that Zhongjiao Machinery has set a new benchmark in the field of hard rock sand making. Now we are launching a "special solution", and the first 10 contracted customers can enjoy discounts!

English

English

中文

中文