High-efficiency lime project in Luzon, Philippines

The intelligent lime production line of ZOOMJO GROUP gives us a head start in the Southeast Asian market! The whole line adopts modularized design, heat consumption is reduced by 22%, the activity degree is stable above 380mL, and the dust emission is only 6mg/m³, which is far beyond the Philippine DENR environmental protection standard

Customer Feedback

“The intelligent lime production line of ZOOMJO GROUP gives us a head start in the Southeast Asian market! The whole line adopts modularized design, heat consumption is reduced by 22%, the activity degree is stable above 380mL, and the dust emission is only 6mg/m³, which is far beyond the Philippine DENR environmental protection standard. --Manuel Reyes, Operations Director of Luzon Building Materials Group, Philippines

Production line configuration

| Equipment | Model | Quantity |

|---|---|---|

| Heavy-duty plate feeder | BWZ-800×3000 | 1 unit |

| Intelligent belt conveyor | STJ800 | 12 sets |

| High-efficiency rotary kiln | Φ3.2×50m | 1 unit |

| Five-stage cyclone preheater | CDC-5X | 1 set |

| Planetary cooler | XLC-600 | 1 unit |

| Laser particle size sorter | LSS-200 | 1 unit |

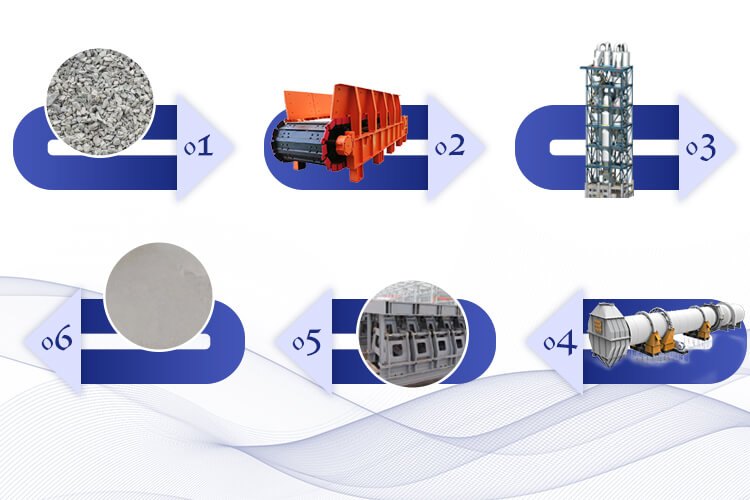

Production process

1. Intelligent raw material processing system

Three-dimensional warehousing: limestone (particle size 25-50mm) is sorted by three-dimensional laser scanning, impurity ores with magnesium content >2% are eliminated, and the purity is increased to 99%.

Pre-decomposition optimization: Qualified raw materials enter the five-stage preheater and are preheated to 850°C through 1100°C exhaust gas at the end of the kiln, with a decomposition rate of ≥30%, reducing the heat load in the kiln.

2. Low-carbon calcination process

Oxygen-enriched combustion technology: rotary kiln adopts biomass gas + pulverized coal dual-fuel system (substitution rate ≥ 20%), kiln temperature control precision ± 5 ℃, calcined belt temperature stabilized at 1250-1350 ℃.

Nano thermal Insulation Coating: Kiln surface temperature is reduced by 50℃, thermal efficiency is increased to 82%, and CO₂ emission per ton of product is reduced to 650kg.

3. Deep cooling and intelligent sorting

Grate cooler: cools the material to 65 degrees Celsius and discharges it from the cooler

Particle size control: After cooling the material through the laser particle size sorter, 0-5mm fine powder is used for the production of desulfurization agent, 5-40mm particles are used as raw materials for steel making, the resource utilization rate reaches 100%.

English

English

中文

中文