High-efficiency grinding project in Quang Ninh Province, Vietnam

Quang Ninh Province in Vietnam has the best talc resources in Southeast Asia, but due to backward processing technology, the product has long been stuck in the low-end market below 200 mesh. In 2023, ZOOMJO GROUP will build an intelligent talc deep processing base for Halong Company to address the problems of 90% humidity in the rainy season and high silicon impurities (5-8%) in the raw materials in the region. It will be equipped with 2 fully automatic production lines, integrated ultrafine grinding and surface modification technology, and promote the upgrading of Vietnam's talc industry from rough processing to high value-added fields such as pharmaceutical and food grades.

Customer feedback

The talc grinding production line of ZOOMJO GROUP makes us stand out in the Southeast Asian market! The investment cost of the whole line is 15% lower than that of local equipment, energy consumption is reduced by 25%, and dust emissions are only 1.5mg/m³, far exceeding the standards of the South Environmental Protection Administration (VEA). The intelligent fault prediction system warns of equipment abnormalities 48 hours in advance, with zero downtime in 3 years of operation and an annual profit increase of 50%!" --Nguyen Van Hung, General Manager of Halong Mining Company in Vietnam

Project Overview

Quang Ninh Province in Vietnam has the best talc resources in Southeast Asia, but due to backward processing technology, the product has long been stuck in the low-end market below 200 mesh. In 2023, ZOOMJO GROUP will build an intelligent talc deep processing base for Halong Company to address the problems of 90% humidity in the rainy season and high silicon impurities (5-8%) in the raw materials in the region. It will be equipped with 2 fully automatic production lines, integrated ultrafine grinding and surface modification technology, and promote the upgrading of Vietnam's talc industry from rough processing to high value-added fields such as pharmaceutical and food grades.

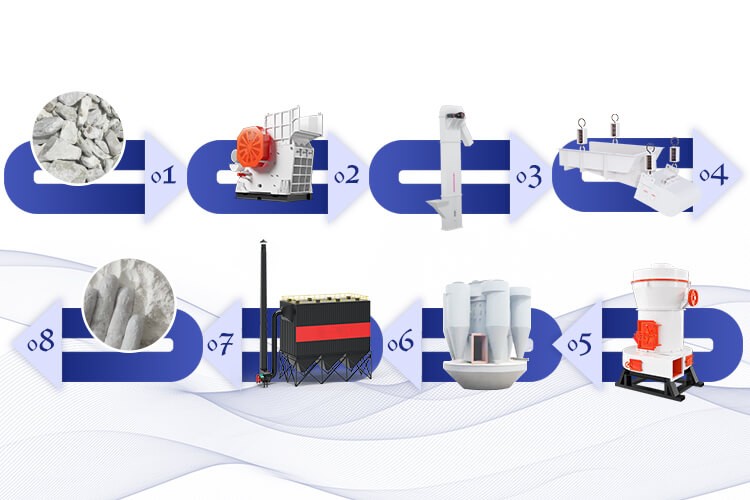

Production line process

1. Intelligent crushing and purification

Jaw crusher: The raw ore is crushed to ≤30mm by jaw crusher, equipped with hydraulic overload protection system, and the crushing efficiency is increased by 60%.

Photoelectric sorting: After crushing, the material passes through the X-ray fluorescence sorter to accurately remove impurities such as quartz and dolomite, and the purity reaches 99.8%.

2. Raymond mill ultrafine grinding

Nano-level grinding: Zirconia ceramic grinding roller + silicon carbide liner, finished product fineness covers 300-500 mesh, D90 particle size control accuracy ±1μm.

Anti-humidity and heat design: The core bearing is equipped with nitrogen seal + dehumidification module, which can operate stably in an environment with a humidity of 95%.

Online modification: Through plasma surface treatment technology, the antibacterial and dispersibility of powders above 400 mesh are improved.

3. Precision grading and sterile packaging

Turbine ultrafine classifier: dynamic adjustment, 500 mesh powder accounts for ≥98%, fineness error <±0.3%.

Medical grade collection: finished products are collected by high-efficiency filter, microbial control <50CFU/g, in line with USP/EP pharmaceutical standards.

Fully automatic packaging: using aseptic ton bag filling line, equipped with inert gas filling function, to meet the needs of moisture-proof shipping.

Technical highlights

Adaptability to extreme climates: The device shell is made of 316L stainless steel + nano-hydrophobic coating, and the circuit system is IP69K certified to resist typhoon and salt spray corrosion.

Circular economy: The sorted tailings are used for soil improvement in the Red River Delta, and the waste heat is used for pre-drying of raw materials through heat exchangers, with the comprehensive resource utilization rate reaching 99%.

English

English

中文

中文