Green Cement Project in Java, Indonesia

The intelligent cement production line of ZOOMJO GROUP allows us to take the technological high ground in the Southeast Asian market! The whole process automation design from limestone crushing to clinker calcination, the failure rate is less than 0.5%, the heat consumption is reduced to 2700kJ/kg, the dust emission is only 5mg/m³, and it easily passes the environmental protection certification of SNI Indonesia. More critically, the project payback period is 40% shorter than expected, truly realizing a win-win situation for both efficiency and environmental protection!

Customer Feedback

“The intelligent cement production line of ZOOMJO GROUP allows us to take the technological high ground in the Southeast Asian market! The whole process automation design from limestone crushing to clinker calcination, the failure rate is less than 0.5%, the heat consumption is reduced to 2700kJ/kg, the dust emission is only 5mg/m³, and it easily passes the environmental protection certification of SNI Indonesia. More critically, the project payback period is 40% shorter than expected, truly realizing a win-win situation for both efficiency and environmental protection!”

--Bambang Sutrisno, Production Director, IndoCement Group, Indonesia

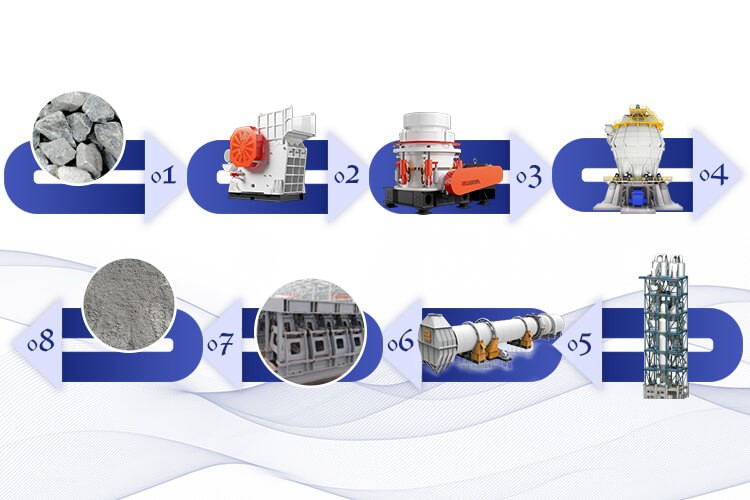

Production Line Process

1. Intelligent crushing and pre-homogenization

Graded crushing: Limestone is roughly crushed to ≤100mm by jaw crusher, and then finely crushed to ≤30mm by multi-cylinder hydraulic cone crusher.

Digital pre-homogenization: Raw material enters pre-homogenization warehouse, adopting proportioning algorithm, CaO fluctuation control <±0.2%.

2. Raw material preparation and decomposition

Vertical roller mill: grinding power consumption ≤26kWh/t, with nano-coated dust collector, dust emission <8mg/m³.

Preheat decomposition system: raw material decomposition rate ≥97%, heat consumption as low as 2650kJ/kg-clinker.

3. Calcination and cooling in rotary kilns

Φ6.0×95m rotary kiln: adopting gradient composite refractory lining, free calcium of clinker ≤0.8%, 28-day compressive strength ≥58MPa.

Grate cooler: heat recovery efficiency ≥78%, discharge temperature ≤ ambient temperature +15℃.

4. Cement grinding and intelligent logistics

Roller press final grinding system: the specific surface area of cement is controlled at 360±5m²/kg, and the power consumption per ton of powder is ≤30kWh.

Unmanned shipment: Finished products are accurately measured by ship loading system, and the shipment efficiency reaches 300 tons/hour.

English

English

中文

中文