350-450 tons per hour mobile granite crushing production line in Sumatra, Indonesia

"ZOOMJO GROUP's mobile crushing station allows us to flexibly operate in three different mining areas, and the daily processing capacity of a single device exceeds 4,000 tons!" - Mr. Budi Santoso, Director of Mining Operations at PT Mandiri, pointed out: "The stability of the equipment in the tropical rainforest environment is far beyond expectations, and it can work continuously for 300 hours without failure during the rainy season."

Customer feedback

ZOOMJO GROUP's mobile crushing station allows us to flexibly operate in three different mining areas, and the daily processing capacity of a single device exceeds 4,000 tons!" - Mr. Budi Santoso, Director of Mining Operations at PT Mandiri, pointed out: "The stability of the equipment in the tropical rainforest environment is far beyond expectations, and it can work continuously for 300 hours without failure during the rainy season."

Project Background

To meet the needs of Indonesia's largest infrastructure project, PT Mandiri needs to:

✔ Adapt to the transfer of multiple mining areas (4-5 times per year)

✔ Comply with Indonesia's new LH environmental protection regulations (implemented in 2024)

✔ Crushing high-hardness granite (Mohs hardness level 7)

Compared with traditional production lines, the mobile crushing and screening combination solution provided by ZOOMJO GROUP:

Investment savings of 40%

Installation time shortened to 48 hours

Transfer costs reduced by 60%

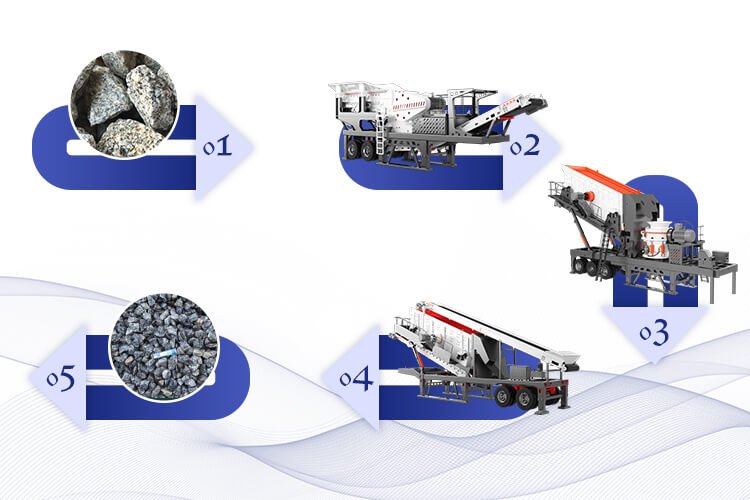

Process

Crushing system:

Coarse crushing: mobile jaw crusher (hydraulic adjustment of discharge port)

Fine crushing:mobile cone crusher (intelligent iron protection)

Precise screening:

YK2160 mobile screening station achieves three-level classification

Finished products are directly loaded onto trucks via a retractable stacking belt conveyor

Core device configuration

| Equipment type | Special tropical design |

|---|---|

| Mobile jaw crusher Plant | Moisture-proof electric control cabinet |

| Mobile cone crusher Plant | Enhanced cooling system |

| Mobile screening station Plant | Anti-mold screen |

| Dust removal system | Rainforest-grade waterproof design |

Operational advantages

Flexible transfer: The entire station can be moved in just 8 hours (including commissioning)

Energy saving and environmental protection: Hybrid power saves 30% of fuel

Quality of finished products: MB value of machine-made sand < 0.7 (special standard for high-speed rail)

English

English

中文

中文