300 tons per hour coal gangue comprehensive utilization production line in Gauteng Province, South Africa

"ZOOMJO GROUP's gangue solution has made us a leader in the Johannesburg mining waste treatment market! The equipment has been running for 9 months without any failures. "

Customer feedback

ZOOMJO GROUP's gangue solution has made us a leader in the Johannesburg mining waste treatment market! The equipment has been running for 9 months without any failures;——Pieter van der Merwe, Operations Director of Minergy

Project Background

South Africa, as the largest coal producer in Africa, produces more than 60 million tons of coal gangue every year. Minergy invested about 2 million US dollars to build the ZOOMJO GROUP coal gangue treatment system. The core requirements are:

✔ Adapt to the plateau climate (1,800 meters above sea level)

✔ Pass the DMR mining waste treatment certification

✔ Equipment maintenance cycle > 800 hours

ZOOMJO GROUP's solution saves 35% of investment compared to European suppliers, and the actual production capacity reaches 330t/h.

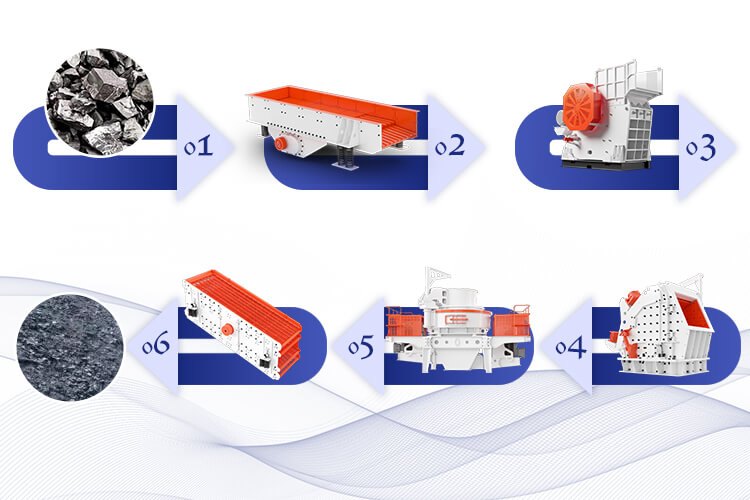

Process

Pre-screening system:

ZSW490×110 feeder equipped with iron removal device

Spray dust suppression system (adapted to arid climate)

High-efficiency crushing combination:

Coarse crushing: PE-600 jaw crusher

Medium crushing: PFV1520 impact crusher

Environmental control:

Dry dust removal system (dust<15mg>

Core device configuration

| Equipment name | Model | Special solution for South Africa |

|---|---|---|

| Vibrating feeder | ZSW490×110 | Vibrating feeder |

| Jaw crusher | PE-600 | Jaw crusher |

| Impact crusher | PFV1520 | Impact crusher |

| Fine crusher | 1600×1600 | Fine crusher |

| Vibrating screen | 3YK2460 | Vibrating screen |

Operational Results

Resource utilization rate: The comprehensive utilization rate of coal gangue reaches 92%

Economic benefits: Processing costs per ton are 65 rand lower than landfilling

Environmental benefits: Obtain carbon trading credits

English

English

中文

中文