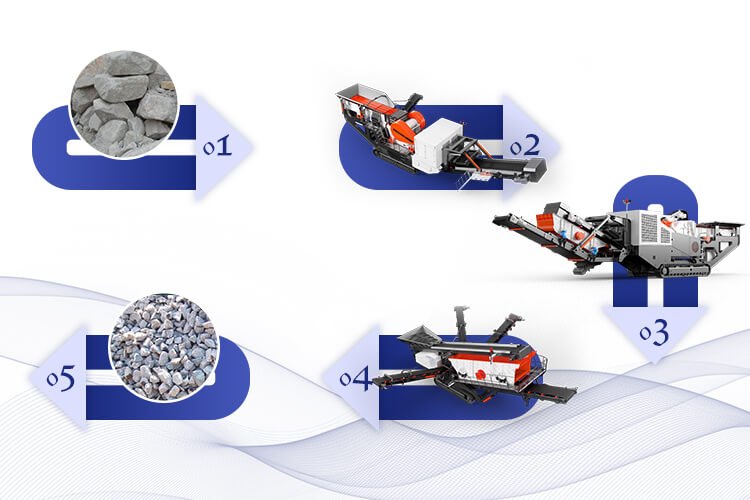

200 tons per hour limestone mobile production line in Lang Son Province, Vietnam

"ZOOMJO GROUP's mobile production line has completely changed our production model!The equipment has been running for three months without any failures, and the quality of the finished product has made our cement factory customers very satisfied." - General Manager of Vietnam Building Materials Company

Customer feedback

"ZOOMJO GROUP's mobile production line has completely changed our production model!The equipment has been running for three months without any failures, and the quality of the finished product has made our cement factory customers very satisfied." - General Manager of Vietnam Building Materials Company

Project Background

As a major building materials supplier in northern Vietnam, Mr. Nguyen's company has long used fixed production lines. With the surge in infrastructure projects along the China-Vietnam border, traditional production lines face three major challenges:

The scattered mining areas lead to high raw material transportation costs.

Fixed production lines have complex environmental assessment procedures.

It is difficult to quickly respond to the diverse needs of different customers.

Design

Innovative design highlights:

✔ Economical configuration: compact design with an output of 200 tons per hour, 40% lower investment than European and American brands.

✔ Intelligent control system: supports Vietnamese operation interface and real-time monitoring of equipment status.

✔ Environmental protection compliance: integrated pulse dust removal system, dust emission <20mg/m³.

✔ Fast transfer: the entire station migration only takes 8 hours (including debugging).

Core device configuration

| Equipment type | Specially designed in Vietnam |

|---|---|

| Mobile jaw crusher plant | High temperature and high humidity resistant electronic control system |

| Mobile impact crusher plant | Quick-change wear-resistant plate hammer |

| Mobile screening station plant | Anti-mildew and anti-rust treatment |

| Dust removal system | Complies with TCVN 5939 standard |

Operational results

Cost savings: 60% reduction in raw material transportation costs.

Market response: Can meet the aggregate needs of 3 different project departments at the same time.

Environmental benefits: Passed the surprise inspection of the Ministry of Resources and Environment of Vietnam.

Customer Testimonials

"We were worried that the Chinese equipment would not be suitable for Vietnam's climate, but now the production line is running stably in the rainy season. We have already placed an additional order for a second set of equipment!" - General Manager Nguyen Van Hung

English

English

中文

中文