Aggregates (sand, gravel, crushed stone, etc.) are core materials used in the construction industry to produce concrete, asphalt, and cement. As the demand for infrastructure grows, an efficiently operated aggregate processing plant has become a highly profitable investment option. Here are the five key steps to a successful plant:

Step 1: Select the target aggregate type

Market-oriented choices determine profit margins

Aggregates are divided into two categories: natural and artificial. The main products include:

Crushed stone: Preferred for concrete and road construction, obtained from crushed natural rock.

Sand (natural sand/mechanical sand): basic material for construction and landscaping.

Crushed stone: used for roadbed paving.

Concrete aggregate: Made from a mixture of sand and gravel, used in general construction.

Selection key: Match the application scenario based on density, water absorption, shape and other characteristics (e.g. high-strength aggregate is required for load-bearing structures).

| Raw materials | Main application industries |

|---|---|

| Limestone | architecture, glass, agriculture |

| Basalt | Roads, refractory materials |

| Dolomite | Ceramics, fertilizers |

| Recycled aggregate | Environmentally friendly construction projects |

Step 2: Factory process design

Fixed or mobile? Flexible choice based on production capacity

Standardized processing process:

Raw material collection: excavator mining (mine/construction waste recycling).

Multi-stage crushing: coarse crushing → medium crushing → fine crushing (particle size ≤ 40mm).

Screening and grading: vibrating screens separate aggregates of different specifications.

Cleaning and impurity removal: improve the purity of the finished product (key step!).

Design points:

Fixed plant: suitable for large-scale continuous production.

Mobile plant: flexible to deal with dispersed mineral sources.

Step 3: Crushing equipment selection

Multi-stage crushing to match rock hardness and production capacity

1.Coarse crushing equipment

| Equipment type | Applicable scenarios | Maximum feed size |

|---|---|---|

| Jaw crusher | High-hardness rock (granite, etc.) | 1200mm |

| Gyratory crusher | Ultra-large output (up to 14,082t/h) | 1300mm |

| Hammer crusher | One-time crushing of soft rock (limestone) | - |

2. Medium and fine crushing equipment

Cone crusher: Highly efficient crushing of hard rocks (such as basalt).

Impact crusher: Soft rock shaping, reducing needle-shaped particles.

Step 4: Efficient screening system

Accurate grading to increase product added value

Coarse aggregate (>4.75mm): used for roadbed and concrete structure.

Fine aggregate (0.06-4.75mm): mortar and decorative materials.

Recommended equipment:

Circular vibrating screen: large processing capacity, anti-clogging.

Linear screen: applicable to both wet and dry screening.

Step 5: Deep cleaning process

Purity determines product premium

| Equipment type | Advantages | Applicable scenarios |

|---|---|---|

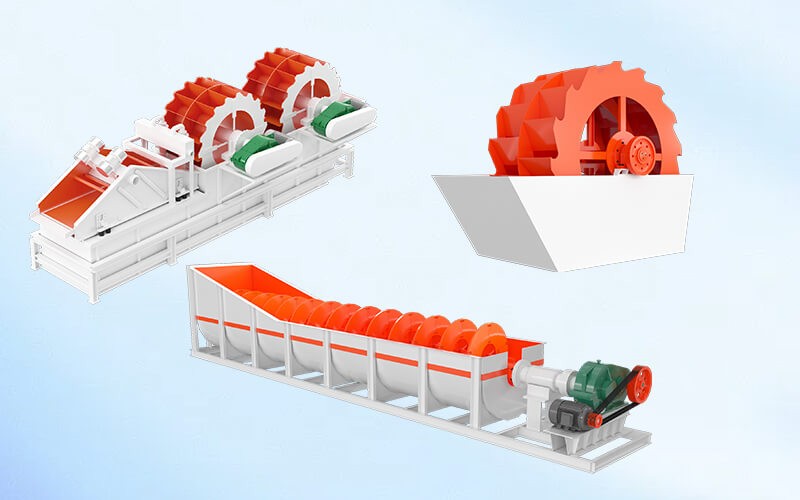

| Bucket sand washing machine | Small footprint, 350t/h efficient processing | General cleaning needs |

| Spiral sand washing machine | High cleanliness, but high loss of fine sand | High-quality concrete raw materials |

Summary

From model selection to cleaning, every link affects the final profit. ZOOMJO GROUP provides customized aggregate production line solutions to help you quickly start production and maximize profits.

English

English

中文

中文