1. Gold ore types and pretreatment

Main gold ore types:

Placer gold ore: Direct extraction through gravity separation.

Rock gold ore (Carlin type/volcanic type/iron cap type): requires a combined process of crushing-grinding-ore dressing.Pretreatment process:

Placer gold ore: ore washing → desludging → gravity separation.

Rock gold ore: three-stage crushing (jaw crusher + cone crusher + impact crusher) → ball milling → classification.

Ⅱ. Comparison of the five major gold extraction technologie

| Methods | Applicable ores | Recovery rate | Core advantages | Limitations |

|---|---|---|---|---|

| Cyanide method | High-grade gold ore (Au:Ag>5:1) | 85%~95% | Mature technology, low cost | High environmental risk |

| Carbon-in-pulp process (CIP/CIL) | Oxide ore, mud ore | 90%~98% | No need for solid-liquid separation, high activated carbon adsorption efficiency | Large equipment investment |

| Resin-in-pulp process | Complex polymetallic ore | 88%~93% | Strong wear resistance, no organic pollution | Poor adsorption selectivity |

| Flotation method | Sulfide ore, fine-grained gold | 80%~90% | Can enrich a variety of metals | High reagent cost |

| Gravity separation | Placerous gold, coarse-grained gold | 70%~85% | No chemical pollution, simple operation | Low recovery rate for fine gold |

Ⅲ. Detailed explanation of key technologies

1. Cyanidation method

Process:

Grind the ore to -200 mesh → Leach with sodium cyanide solution (48~72 hours).

Zinc powder replacement precipitation → Electrolytic purification.

Optimization direction:

Use ozone oxidation to replace cyanide (environmentally friendly process).

2. Carbon-in-Pulp Method (CIP/CIL)

Core differences:

CIP: leaching first and then adsorption, suitable for high-grade ores.

CIL: leaching and adsorption are synchronized, suitable for low-grade ores.

Equipment: High-efficiency desorption electrolysis system can reduce energy consumption by 30%.

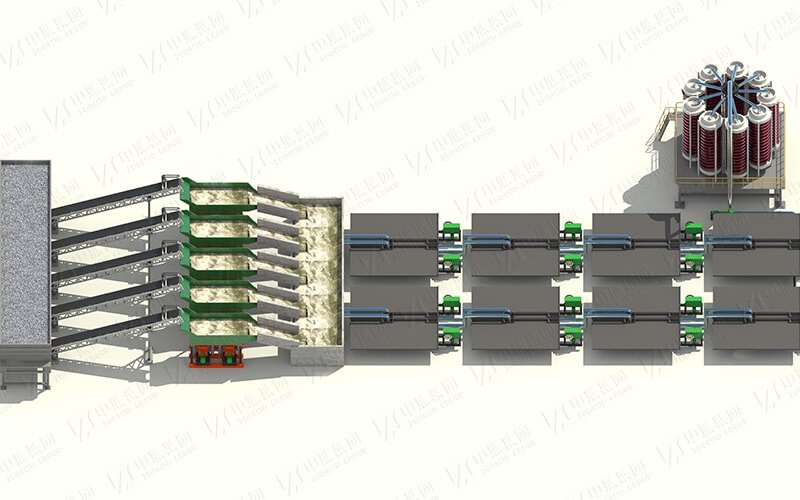

3. Gravity separation

Equipment selection:

Jigging Machine: Processing particle size 0.04~50mm, recovery rate>80%.

Shaking table: Sorting 0.037~3mm fine gold, the concentrate grade increased by 5 times.

Spiral chute: Low-cost processing of 0.03~0.6mm ore.

Ⅳ. Practical suggestions for improving recycling rates

Combined process:

Rock gold ore: gravity pre-selection + flotation + cyanidation (recovery rate increased by 15%).

Placer gold ore: spiral chute + shaking table (fine gold recovery rate > 90%).

Equipment upgrade:

The ball mill uses rubber lining, which doubles its lifespan.

The flotation machine is equipped with a microbubble generator, which reduces the amount of reagents used by 20%.

English

English

中文

中文